How to make silent sewage: an overview of the methods of the

Agree, the silent sewage system today is not a whim, but a real necessity. At least, because in most modern apartments there are plastic risers that perfectly convey the sound of flowing streams of water and various sewage.

Previously, such a problem did not exist, because highways were made of cast iron, and this metal due to its structure almost completely absorbed all such sounds.

However, this was probably the only advantage of the old systems. Now they have been abandoned in favor of plastic for many reasons - we will consider them in the comparative table below.

| Cast iron properties | Plastic properties |

| 1. Great weight | 1. Pipes from this material are very light, which greatly facilitates work with these products. |

| 2. Low level of corrosion resistance | 2. Plastic does not rot and does not rust, and because of this its service life is very high |

| 3. The cast-iron sewer riser is difficult to install and repair. | 3. The PVC system is quickly assembled and, if necessary, its problematic elements can be easily replaced. |

So, it turns out that the use of plastic products for the assembly of sewage is definitely more appropriate.

However, there is a specific minus - it is the inability of plastic to suppress noise from liquids passing inside it.

In this article we will look at how this flaw can be eliminated with your own hands.

The device is silent sewage

It should be noted that we will consider only the most popular and time-tested methods that really "work"

As a first illustrative example, let's take a situation where sewage is only planned.

Installation from scratch

In this case, I mean that the riser itself is not there yet, and the work is at the stage of buying the material. This is where an interesting and effective solution is hidden - the fact is that there are special silent sewage pipes for sale. Let's take a look at what it is.

In fact, these are the same plastic products, only they consist of three layers. The inner and outer layers of this type of products are made of PVC, while the middle layer is made of a soft material like foam rubber.

Please note that this technology really allows you to suppress most of the sounds, but it is not always possible to do this at 100%. Much more depends on how and how the riser is sheathed, how many turns the sewer system has, etc. Therefore, doing such work, try to take into account the maximum factors.

In general, the material is very good, and its only drawback is the high price.

You need to mount the system based on such moments:

- Try to plan the highway so that it has a minimum of sharp turns.. After all, the more there will be such bends, the more resistance the fluid will meet on its way. Accordingly, there will be more "sources" of noise.

- Do not save and buy cheap sewer fittings. Cranes, adapters should be of high quality in the sense that on their inner plane there should be as little as possible protrusions, which theoretically can interfere with the "smooth" passage of water.

- You should not use pipes of small section, where the norms require a large diameter pipe. The fact is that if the fluid passes through the track with a small diameter, then the pressure will be greater. And this is at least the cause of vibration.

Tip: try to lay silent pipes for sewage in a separate utility room. Or, alternatively, you can sheathe the trunk with a special box. Such a set of measures will allow to minimize the noise level in the apartment or in the house.

Now let's understand what to do if the riser is already mounted and the most common plastic pipes are used.

Sound insulation of existing sewage

So, it turns out that we have, in general, a fairly standard situation: a PVC system that needs to be soundproofed as much as possible.

The first method is carried out according to the following scheme:

- If the pipes are located in a niche, then it is necessary to wrap them with some dense material. For example, mineral wool is perfect for this task. If there are no funds to buy it, then you can use old blankets, jackets, etc.

- Next you need to cover the niche as it were. That is, simply speaking, sheathe it with boards, plywood or any other sheets. It is important to understand that the thicker and denser the skin will be, the worse the sound will penetrate through it.

For your convenience, we publish a table with insulators suitable for wrapping pipes.

| Material type | Practical properties |

| 1. Foam polyethylene | Differs in the small weight and small thickness. It is very convenient in work that the speed of installation is high. Able to absorb about 30% noise |

| 2. Fiberglass (for simplicity, glass wool familiar to everyone) | The material is great for outdoor use. Good sound insulator and in addition a great heat barrier |

| 3. Modern mineral wool | Such a heater is not afraid of fire, it is relatively inexpensive, and besides it absorbs noise well |

| 4. Synthetic rubber | It is mainly used where low temperatures are present. The insulator has a very tight connection - the seam is glued together and due to this it turns out very tight |

| 5. Foam rubber | It has a porous structure, low weight. This is a kind of "economy version" of sound insulation of pipes. Efficiency is, but not very good |

Now about the second method - it is more time-consuming, but more effective.

Its essence consists in the following steps:

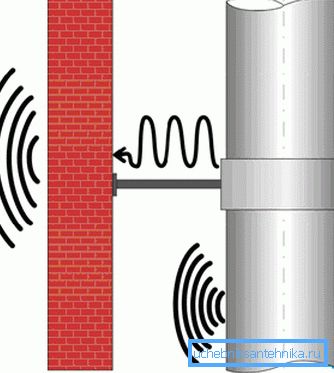

- We seal the entry and exit points of the highway from partitions or ceilings. To do this, you need to clear all the free space around the pipes in the places where they pass through brick or concrete. And after that everything should be blown out with ordinary foam.

- It is very important to fix the pipes well. That is, it is necessary to make sure that the “route” does not dangle from side to side during the vibration arising due to the passage of water flows, but is reliably fixed. Here in the case are special fasteners and clamps with rubber gaskets inside.

Tip: in principle, it is not necessary to purchase fittings whose price is too high. It is quite possible to save. Use the most common metal fasteners, and make rubber seals yourself (for example, from bicycle or car cameras).

Well, the third step is that the pipes (as in the previous method) are wrapped with insulating wool and closed with a lid or box.

The box can be made from any wooden sheets, or from drywall. In this case it would be great if the main sheets are on top (or from the inside of the box) are also sheathed with expanded polystyrene.

And one more variant of how you can make silent sewage pipes yourself is to sheathe them with a special sound insulating membrane.

This membrane is rather thin compared to the same mineral wool, however, it still gives a certain effect. It is made of dense foam rubber or rubber. Externally, the material resembles pipes, which have a longitudinal section along its entire length.

The membrane simply puts on a plastic or any other pipe, and then turns into a special tape. Or as an option - instead of tape, you can fasten it with wire or even ropes.

The advantage of the technology lies mainly in the fact that such foam rubber products are relatively inexpensive and can be “put on” the main line very quickly.

In addition, this material does not need additional coatings, unlike the same mineral wool, which must be protected with something from above. Otherwise, it will pollute the air with small particles of glass and basalt.

Well, the disadvantage of using a membrane is that it is impossible to soundproof a sewage system in this way by 100%.

On this our review is over. Let's summarize the article.

Conclusion

As you can see the instructions for the device silent sewage is quite simple. Such a system is quite realistic to do yourself. And both from scratch, and to improve the already existing highway.

We have provided you with the general principle of technology, we hope that the information will be useful in business. If you want to know even more, then check out the video in this article.