Installing a shower tray - features of the work yourself

If you decide to build a shower stall yourself or purchase a ready-made version and install it, then you need to know the main features of the installation operations. And if some work can be done in only one way, then others are done differently.

For example, there are several options for carrying out this type of work as installing a shower tray - on bricks, on special supports, on an even basis, it all depends on the type of construction.

We will consider the main types of pallets and decide how best to fasten each of them in order to ensure maximum reliability and durability.

Types of pallets

On the market you can find several versions of the base for shower corners and cabins, consider the most common ones:

| Cast iron | This option is distinguished by a low price with a rather impressive reliability and durability. The material can withstand even very strong shocks, but the enamel from such adverse effects cracks, which degrades the appearance of the surface. Of the minuses, you can select a fairly large mass of products. |

| Steel | Difference from cast iron is a much smaller wall thickness, which significantly reduces the strength and increases the noise level that occurs when water is turned on. In general, this option can be considered the most budget, but at the same time its longevity leaves much to be desired. |

| Ceramic | These options are made of porcelain (cheaper) or earthenware (more expensive, but more attractive), their main advantage - an attractive appearance and sparkling surface. Among the shortcomings, it is necessary to highlight the fact that when heavy objects fall, they can simply split, so when operating it is necessary to observe accuracy. |

| Acrylic | A very interesting solution that is most popular due to the following factors: low cost, low weight of the structure, very attractive appearance and just a huge choice of colors and shapes. Among the shortcomings can be identified weak resistance to high loads, because of what the surface bends and can crack. |

| Marble | This option is distinguished by the beauty of natural stone, the highest reliability and durability, but it also costs ten times higher than other options, which is why it is practically not common. |

Tip! Never save on quality and choose options not from the budget, but at least from the middle price segment, since the cheapest models often leave much to be desired and are very unreliable.

Main types of work

Consider how to install the shower tray with your own hands, depending on the material of manufacture.

Acrylic designs

The most common option, which we consider first.

You will hold the following events:

- First of all, the assembly instructions are being studied, believe me, if you have never done such work, then without careful study of each item, you are unlikely to succeed.. Therefore, take this recommendation seriously and sort out every detail of the workflow.

- First of all, it is necessary to assemble a frame that provides the rigidity of the structure and carries the main load bearing, ideally, it should be a one-piece element that is attached to the body through the leg connections. Best of all, the options of stainless steel have proven themselves, but also the usual high-quality painted systems last long enough.

Tip! Some options are not equipped with a frame, but only supporting legs that are attached to the surface, it is better not to use such options, since their rigidity is much lower, because there is no solid frame, which serves as a reliable basis.

- Next, you need to attach the siphon and connect it to the sewer system, after which it is recommended to pour a bucket of water to check the tightness. If there are leaks, they should be fixed.

- After that, using the level, the position of the structure, this is done simply: all the legs of the system are adjustable, it is enough to twist them in the right direction. When this work is completed, the points of fastening of the pallet to the wall are marked on the wall, usually there are four of them - two on each side, then the structure is shifted and holes for fasteners are drilled in the wall.

- After fastening, it is recommended to treat the abutments to the wall with sanitary sealant to prevent moisture penetration under the pan.

Ceramic options

If you have to install a shower corner with a pallet with your own hands, then it is best to have the ceramic option included, as it provides good reliability and is placed directly on the floor surface.

Works are performed as follows:

- First of all it is necessary to bring the drain sewer pipe to the right place.. In addition, you will need a niche in the floor for the location of the siphon there. A certain part is cut out in the wooden surface, and a niche is made in the concrete with a perforator (or even better, when filling the platform, to provide for this question and insert a bar, which is removed after setting).

- It is important that the base is smooth, if necessary, it can be corrected by a self-leveler., if the tile will be laid on the floor, then it is better that it lay under the tray, this makes the situation more accurate.

- When installing, a siphon first joins, after which the system is put in place, and water pours into it. After that, the structure is lifted and all joints are checked for leaks. If everything is in order, you can proceed to the mount.

- For fixing the pallet, the tile adhesive is kneaded and applied on the base, after which the structure is put and gently pressed, at the same time, the level is checked for correctness

Iron and steel pallets

The most reliable option for installing such options is the use of brickwork, the works are performed as follows:

- First, the sewer pipe is brought to the right place., it is important that it is located as close as possible to the sink on the pallet.

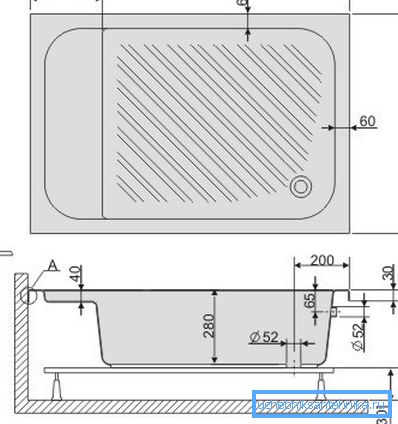

- Next, brickwork is made, its outer edge must correspond to the size of the structure, and the height must be such that the bottom does not touch the surface., and there was enough space for a flat siphon. During the work, the usual masonry mortar is used and any bricks that are on hand are used.

- In order for the design to gain strength, you need 2-3 days, then you can proceed to further work. To begin with, the drain is checked as described above, and, if everything is normal, it is possible to fix the pallet, for this, the brickwork around the perimeter is smeared with mortar and the structure is gently pressed and leveled.

- Subsequently, the visible parts of the brick can be revetted with the same tile as the walls or the floor, or it can be finished in any other way..

Conclusion

Proper installation of the tray ensures the reliability and stability of the entire shower structure, so pay close attention to this issue. The video in this article will tell some important facts from the topic discussed and will help to get to the heart of the matter even more deeply.