Marble sink: natural stone and artificial counterpart

People carry out hygienic procedures daily, therefore practically in each dwelling there are special devices for washing and rinsing hands. The most sophisticated option is a marble sink, which allows not only to ensure the implementation of the above activities, but also to give a separate part of the room an interesting look.

Material review

The stone used for the manufacture is a rock that includes calcite and some impurities of other minerals with organic compounds. Its density usually ranges from 2.3-2.6 g / cu. see. The formation of the source material occurs through metamorphism, when the structure of limestone changes significantly under specific physico-chemical conditions.

Natural stone

In this case, the raw materials are obtained naturally in the external environment. The deposits are located in many regions of our country, but Karelian marble is considered the most popular. The largest deposits are also noted in the Urals (read also the article Double shell: why it is needed, what is good and what are the nuances).

Products from this stone have high aesthetic characteristics. For example, a marble sink for a kitchen or bathroom can transform the internal space. In addition, the finished product of this material is environmentally friendly.

Among the shortcomings, it can be noted that the price of manufactured products is quite high, which is associated with the complexity of processing the material and its extraction.

Artificial counterpart

With this option, the stone is obtained by artificial means, so its cost is much lower. If necessary, the sink of molded marble can be made by hand.

The following are the most important advantages of products from this material.

- Products have sufficient strength to mechanical stress, and therefore do not require excessive caution during operation.

- Resistance to various chemicals provides an opportunity to carry out cleaning with special means.

- The durability of the finished product is quite high. It can be used for a long period of time.

- The artificial stone is easy to process, therefore it is possible to make holes for the crane and other elements without any special problems.

Addition! Sinks from cast marble for a bathroom or kitchen are not inferior to products made of natural stone in terms of aesthetic and strength characteristics, so they can be successfully used in residential buildings.

Color shades

White color indicates the absence of additional inclusions, however, some streaks can still be observed. This type of stone is much easier to grind and cut.

The rock of gray shades may have a fine-grained or coarse-grained structure. Usually in the total mass it is possible to isolate a large number of light or dark patches.

Green color is given to the material by silicates containing iron in their base. If the rock contains manganese and limonite, then the stone acquires a pleasant beige color. Most rarely there are blue tones, as blue diopside is not very common.

Red marble is considered the most valuable, because it looks original in any design decisions. Hue material acquires due to the content of a large amount of iron oxide.

So that the marble sink for the bathroom or kitchen fits well into the interior, you need to choose the right color scheme.

Manufacturing process

Products made of artificial marble can be made independently. This will allow not only to save resources, but also to build an exclusive bowl, and the handmade work is now very much appreciated.

Below is information on how to make a sink from cast marble.

- First a special form must be made or purchased.. Its interior is completely processed with a wax separator to make the product easier to remove. That is, when they are used, an anti-adhesive barrier is created between the product and the container.

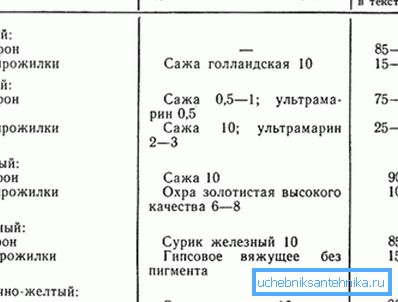

- After that, the gelcoat is sprayed, which will act as a decorative protective coating for the products being manufactured.. Substance consists mainly of epoxy resin, mixed with the necessary dyes. On the matrix composition should be applied evenly.

- Then you can proceed to the preparation of the basic solution.. To do this, mix cement with pebbles and sand. When the dry mass is homogeneous, you can add dyes and fillers. Water and plasticizers are added to the bulk solution, followed by thorough mixing.

- At the last stage, the liquid solution is poured into the matrix and aged for a day, but the product will pick up the final strength after a longer period. After 24 hours, the artificial marble sink can be removed from the mold.

Attention! To reduce the porosity of the finished product, it is necessary to expel the maximum possible amount of air. For tamping the mixture is recommended to use vibration installation.

As a conclusion

Above was presented the instruction that allows you to make a marble bowl by artificial means, but for elegant interiors, it is desirable to use sinks made of natural stone. Then the dwelling will be dominated by an atmosphere of luxury and wealth, which, if there are large financial resources, may be relevant (see also the article What kind of stone sink is used for the kitchen and bathroom).

For a visual presentation of thematic information posted a video in this article.