Metal shower tray: choose the type of material and put the

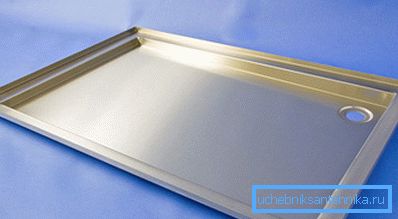

Metal shower trays are not as varied in shape and design as their acrylic, quarian and plastic counterparts. They heat up for a long time and are quite noisy. However, the material has its undoubted advantages. Metal shower tray and will be the subject of study in our article.

Types of fixtures

Products are classified according to several criteria.

Types of metal

Such plumbing fixtures are made of cast iron, steel, stainless steel and black iron, enameled.

- Cast iron is reliable, strong and very durable, it can serve for many decades.. Although it heats up slowly, however, heat retains well. Like baths, cast iron trays are coated with white or colored enamel. The main disadvantages of the variety are a large weight, a small variety of designs and shapes. The mass of the device for its operation does not matter, however, it creates difficulties during transportation and installation. As a result, the price of these services increases.

- Black steel pallets are necessarily enameled to enhance their aesthetics and rust protection.. They also heat up slowly and have a low degree of sound insulation. However, such products are much easier to cast iron with a high level of strength. The reliability of products to a large extent depends on their thickness.

Note! Quality steel shower trays are enhanced. Manufacturers increase the thickness of their walls with polyurethane and cover with durable enamel.

- Stainless steel fixtures are not susceptible to corrosion and do not need enameling.

Dimensions and shape of the product

When choosing a metal fixture, pay special attention to the thickness of its steel. The thinner the material, the less weight the user can withstand. Due to overloading the pallet will begin to sag. In addition to the loss of aesthetics, this will lead to the destruction of the enamel coating and leakage of the drainage system.

As for the size and shape, the standard are rectangular and square fixtures.

The conventional gradation of the dimensions of the products is as follows:

- the smallest devices - 70x70 cm;

- medium fixture - metal shower tray 80x80;

- the largest ones are analogues of 90x90 cm.

The bottom table shows the product parameters.

| Dimensions, in cm | Depth, in cm | Steel thickness, in mm |

| Square steel pallets | ||

| 70–70 | 13 | 0.8 |

| 80? 80 | eight | 0.6 |

| 80? 80 | 13 | 0.8 |

| 80? 80 | sixteen | one |

| 90–90 | sixteen | one |

| Semicircular steel | ||

| 80? 80 | sixteen | 0.8 |

| 90–90 | sixteen | 0.8 |

| Metal frame for pallet installation | ||

| 70–70 | ||

| 80? 80 | ||

| 90–90 |

Sometimes on sale there are corner fittings made of steel. Their sizes are the same as those of acrylic counterparts.

The degree of convenience that the shower cabin with a metal tray provides also depends on its depth. Here the product model matters. The depth of the fixtures ranges from 8 cm (shallow) to 16 cm (deep).

Pallet installation

- Installation of the device from metal, unlike acrylic, is impossible without arranging the seat. It is a support for adaptation, at the same time masking engineering communications. The seat can be a finished metal frame or a low pedestal of brick. If such a possibility is provided by sewer communications, then you can simply make a recess in the floors. Usually in apartments and houses drain pipes are located above the floor, so only the first two options are possible.

Laying out a brick pedestal is very simple. Four walls with a height of 15–20 cm are constructed from the blocks. A pallet is placed on them after the masonry mortar has dried.

- Next, you will need to put a siphon. Since space under the pan is limited, its drainage device is combined with a drain hole in one node - a siphon drain hole. Its output can be vertical or horizontal. A specific type is selected based on the type of sewer release in the shower.

- Place the pallet in place, mark the areas of the drain hole and profile. Next, remove the fixture and disconnect parts of the drain. Connect the outlet opening to the sewer outlet. Check the installation of gaskets.

Note! The siphon must be properly connected to the sewer. The instruction recommends using a corrugated (flexible) tube for this. The mediator between it and the socket sewer is a rubber sealing cuff.

- The very installation of a metal shower tray with your own hands can be done by fixing it with silicone sealant or polyurethane foam. The most common method of fixing a plumbing fixture is by wedging it between the tile and the base. This method is suitable only when the pallet is placed before laying the tile on the wall. If the tile has already been laid, the installation of a metal shower tray with its own hands by fixing it to the base with foam or sealant is optimal.

- When the glue dries, all that remains is to revet the parapet (if there is one). In most cases the brick is tiled.

Conclusion

Metal shower trays have both disadvantages and advantages. However, in any case - it is durable and reliable plumbing fixtures. Now manufacturers have significantly improved the aesthetics of their appearance. The video in this article will continue to acquaint you with this topic.