One-section and two-section washing: features

A two-section or single-section sink is installed on a kitchen cabinet or cupboard, but the number of bowls, as a rule, depends on the size of the room and the design of the furniture. Simply put, the longer the kitchen facade, the larger the sink can be installed there, therefore, vessels with two containers will look good only in large rooms.

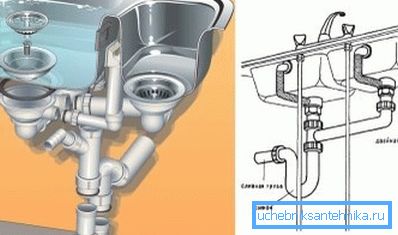

Of course, their installation and connection is somewhat different from the standard, but more on that below, and for a more complete picture, the video in this article is offered to your attention.

Kitchen sinks

Note. All sinks that are used for sanitary purposes can be distinguished by their shape, the number of containers in one device, the material and the method of installation.

Materials

- The most popular material for the manufacture of sinks can be called stainless steel - it is the cheapest, but its technical qualities are always high. Such capacity is not afraid of temperature differences, which is often possible when washing dishes, stainless steel is neutral to various chemically active detergents, it is not afraid of shock and abrasion of the surface.

- In addition, due to the low weight of the device, it is very convenient to mount it yourself - You will not be afraid of dropping the sink on the floor or scratching it with any tool.

- Installation of such sinks on the cabinet or cabinet in most cases is done in an overhead way, and only occasionally, when there is no seat in the worktop, it has to be cut out with a mill or an electric jigsaw.. In form, such shells can be very diverse - round and oval, square and rectangular.

- Often, the container on the left or right side has a corrugated pedestal, which is used for storing dishes when washing it..

- Of course, for more luxurious kitchen interiors, you can use sinks made from natural or artificial stone. (granite, marble), but their price will increase several times.

- In most cases, preference is given to artificial stone - it is much lighter than natural stone and responds well to processing, Yes, and at the cost of products made of artificial stone get a little lower. In addition, for a composite material, you can always change the color, shade and texture - these parameters are determined by the composition.

- So, for the manufacture of a composite, up to 80% of mineral (granite or marble) crumbs of medium or small fraction are used (the texture depends on this), and the remaining 20% are polyester resins, coloring agents (dioxides) and a catalyst for solidification..

- The resulting mixture is poured into a mold of a certain configuration and put on a vibrating table for shrinkage, then, when the product hardens, it is released from the mold.. Finally congealed shell is subjected to grinding on a polishing machine.

- But composite products are not limited to marble and granite - you can also buy a sink made of artificial onyx made using a similar technology, only here 65-67% of aluminum oxide and 2-7% of color paste are used as a filler..

- This filler is mixed with polymer resins, to which a catalyst is added for hardening, the mixture is poured into a mold and placed on a vibrating table.. Then everything happens, as with granite or marble - hardening, release from the form and polishing, only here the instruction requires that the washing should be covered with a special film, since such a composite does not have sufficient strength.

- In addition, you can find a kitchen sink made of ceramics, but it can be either porcelain or earthenware, and it is almost impossible to distinguish them visually (without detailed inspection). The fact is that the earthenware has a less dense structure compared to porcelain, but the finished product is coated with glaze, from which the surface is ideally smooth.

- But ceramics have one serious drawback - it is afraid of temperature extremes and impacts., therefore, you can only use such a sink in the kitchen if you have a dishwasher.

Installation Methods

In the upper photo, you can see how two-piece stainless steel sinks are installed in a laid-on way, however, this also applies to any other sinks (composite, ceramic) that have a different shape. The essence of this installation is that a seat is provided in advance on the cabinet or cabinet, so you just have to fasten a mixer with a siphon to the sink and lower the device into its place.

But the invoice method does not always provide for a ready place for planting - sometimes it is necessary to cut it yourself. However, if the horizontal sides of the shell fall on the tabletop, that is, it is supported on them, then such an installation will be called a consignment note.

Embedded installation differs from the invoice in that the sides of the bowl do not overlap on the tabletop, but are recessed flush, or slightly below this level, as you see in the top photo.

When buying such a sink in a store, you can purchase a worktop with a cut-out complete with it - the sink is installed on the glue and the joint remains almost imperceptible. But sometimes such an opening has to be done on its own and for this it is best to invite a specialist.

Note. The installation methods described above are applicable to all types of sinks.

Conclusion

Connecting double sinks is almost no different from single - the same mixers and the same siphons. But if you need only one tap, then you need to connect two siphons, that is, by the number of drains.