Plastic shower for garden

Now almost every garden plot owners try to install a comfortable summer shower. There are dozens of variants of such structures and each of them is good in its own way. One of the most popular in terms of cost, ease of construction and durability deserved are shower cabins made of plastic for the garden.

Such a design can be bought in the finished form or build your own hands, but first things first.

What does the modern industry offer?

Each of us saw such a useful invention as a mobile bio-toilet. It is a fairly practical booth made of thick plastic and equipped with a module for collecting biomass. But the creators of this design did not stop there, and developed several alternative options for operating the product.

One of these options is a plastic shower cabin to the country. In fact, if you look, the solution lies on the surface. It is only necessary to remove the toilet seat and install a shower tray.

By itself, the design is a modular module, each node of which can be dismantled. Therefore, when buying, there is always the option of picking.

Almost at half of the domestic garden plots there is an acute problem of space deficit. It is for such villas was developed booth, combining a toilet with a shower.

At the same time, the chair was pushed into a corner, made it slightly smaller and was separated from the pallet by a plastic shutter. The result exceeded expectations, in fact, the customer receives the product two in one.

But this is not the only combination. In the presence of a free square meter, you can order a booth, divided by a rigid, stationary partition and a separate entrance. And although her price is higher, this design is more like summer residents.

If funds allow, then of course the best option would be to purchase separate specialized shower and toilet cabins. Thus, the problem of the smell in the shower is solved. Indeed, ideally, the instruction instructs the shower to be installed no closer than 2 meters from the drain hole.

As already mentioned, the majority of firms provide the opportunity to choose a complete set for individual orders, and the price varies depending on the number of additional options. The manufacturer is not so important, what nodes to complete this designer.

Tip: the shower tray in the booth can be connected directly to the septic tank, it will be cheaper. But if you take a two-in-one construction or the drain hole is near, then it makes sense to install a siphon with a dry closure on the pallet. It will block access to sewage gases, plus there is no moisture in it and in case of frost the siphon will not break.

If you want to have warm water guaranteed, then it is better to immediately install a plastic tank with built-in electrical heating elements and a thermostat. It is much more economical and safer than a flowing water heater. In addition, this tank is mounted, instead of the roof and in sunny weather will be heated in a natural way.

Homemade plastic construction

In this case, not every plastic for a shower cabin can be used, the design will be mounted in a sunny place, open to all winds and frost. The best material is now considered cellular polycarbonate, some try to use PVC sheets, but they are thinner and the tightness of such structures leaves much to be desired.

Advantages of polycarbonate

- The shower, sheathed with polycarbonate, without a foundation, that is, one design, is assembled quite quickly. In the presence of material and tools, everything will take you a maximum of a couple of days. And from the tool you need a screwdriver, drill and grinder or hacksaw.

- The elasticity of the sheets allows you to create a variety of models. If you wish, you can build an exclusive booth with a non-standard layout.

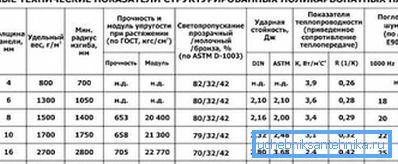

- Often, a double-layer cellular sheet with a thickness of up to 16 mm is used, whose thermal insulation characteristics and durability exceed glass at least 5 times.

- The material is well resistant to forty-degree frost and midday July heat, plus it practically does not react to ultraviolet radiation.

- Cellular polycarbonate is much lighter than glass or metal, so there are usually no problems with transportation and installation.

- Translucent cellular polycarbonate does not need further staining. You just have to choose which color is more suited to the interior of your site, and purchase material of this color.

Tip: when installing polycarbonate, holes and joints should be done with a gap of at least 1 mm. Since this material is able to expand when heated, and when cooled to return to its previous size.

Shower frame

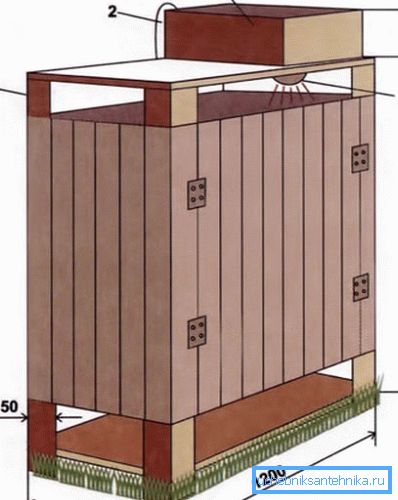

Any construction of such a plan requires a supporting frame, polycarbonate or other material is just a covering. Here you can go two ways. If you are trying to save money, then use a wooden bar, a section of 50x50 mm is enough.

Only previously it will need to be treated with an antiseptic, the cheapest option is to cover the tree with engine oil.

For a more durable and solid structure, a profiled 40x40 or 40x60 mm metal pipe is taken. As you know, this material perfectly bends, therefore, it is possible to make round, oval or any other booths from it.

If you have a metal corner, ranging in size from 25 mm and more, then you can quickly and easily assemble a frame for a shower stall from it. Moreover, in its strength and stability, such a design will surpass all existing analogues.

Tip: if there is a choice between a corner and a shaped tube, take the tube. The thickness of the metal in it is slightly more than 1 mm, so the screws on the metal, which will be attached sheets, it is easy to drill. With a corner this does not work, it will have to pre-make holes for each screw.

The video in this article contains useful tips on the topic.

Conclusion

Shower cabins made of plastic for summer cottage, lightweight construction and do not require a solid foundation. Serial modules can generally be put on bricks and fixed on the ground with staples.

At homemade, it all depends on the design of the drain. You can do a couple of buckets of rubble and a wooden ladder, and you can pour a stationary foundation with a tray.