Polycarbonate shower cubicle on your site

Not every country owner can boast that he has the opportunity to comfortably wash himself after work, but there is a way out for this - these are summer showers for polycarbonate, which you can purchase through a retail network (warehouses, shops and even a network). The Internet).

The properties of this material are such that they allow minimal care for the cleanliness of the booth - the fungus and mold are almost impossible there, and practically every household worker can afford to install such a device. But before you get down to business, let's find out in more detail about this plastic and consider some designs of showers, and in addition, the video in this article is offered to your attention.

Country shower

Properties and features of polycarbonate

Explanation. Polycarbonate is called polymer plastic, which differs from other plastics in a rather unique structure. This material is extruded, as the sheets are made using extrusion of granules. Owing to this method, the finished PC retains all the properties that the granules had before remelting.

- Cellular polycarbonate manufacturing method makes it about six times lighter than glass. This allows you to use the material for the most complex structures without any special difficulties during installation work.

- Considering its molecular structure, the sheets are subjected to the ability of mechanical loads, such as bending and impact.. With proper mounting, the PC is able to withstand quite large loads at pressure (weight, wind).

- Once again, you can pay attention to the honeycomb structure of the material - thanks to this structure, it is an excellent sound and thermal insulation.. This is possible due to the presence of voids inside the air.

- If we talk about showers, the PC is simply perfect here - neither boiling water nor cold water can be used for it, since its temperature range is between -40? C and +120? C.

- The sheets are fairly resistant to chemicals and precipitation, therefore, with the care of them you can use almost any household detergent.

- Due to its flexibility, the PC can be bent almost to large angles, without fear of cracking the material - this factor is very convenient for arranging arched structures and roofs including. Moreover, working with it is safe - it is almost impossible to hurt yourself with polycarbonate, unless you really want to.

| Test parameters | Test Method | Measuring unit | PC |

| Elastic modulus | ISO 527 | MPa | 2200 |

| Ultimate tensile strength | ISO 527 | MPa | 60 |

| Stretching | ISO 527 | % | 80 |

| Permissible tensile strength | ISO 178 | MPa | ?95 |

| Bending modulus | ISO 178 | MPa | 2350 |

| Density | ISO 1183 | Q / cm3 | 1/2 |

| Translucency | ASTM D1003 | % | 86 |

| The softening temperature of the structure (according to Vic) | ISO 306 | ?C | 145 |

| Temperature limit | ISO R75 | ?C | 135 |

| Impact Toughness (Charpy) | ISO179 | KJ / m2 | ?40 |

| Water absorption | ISO62 | % | 0.2 |

Technical characteristics of the finished sheet polycarbonate

We are developing a project

Note. At once I would like to note one important feature of the construction - you will never be hindered by the drawing - let it be the most primitive and even for the simplest and easiest architectural structure. But there are always sizes, both general and detailed, that during installation will serve you as an instruction manual.

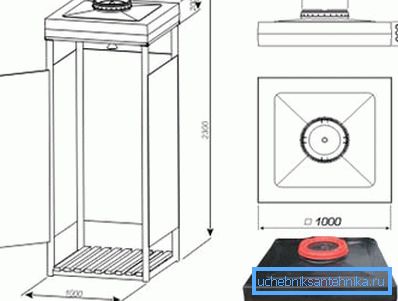

Before you start building and even purchasing material, you need to find out what room sizes you will need and whether there will be a dressing room in the booth - although the price of a PC is not high, but it still makes no sense to overpay when force majeure occurs, for example, with a shortage of 30 cm2 material you have to buy a whole sheet.

Also, you should tie these parameters to the tank size and foresee whether you will use a tubular electric heater (TEN) there. In addition, you have to provide a drain and drainage system - this will allow the water not to stagnate and, thus, avoid unpleasant odors.

Pay attention to the size of your family members or those who will have to operate the shower stall - there should be spacious for any person, therefore, the minimum area should be about a cubic meter (100,100 cm).

This also applies to the height of the room - even the tallest person should not bend down when washing, which means that the height of the watering can sometimes reach 220-230 cm. If a dressing room is provided, then its area can be made a little smaller, but at a minimum it is 0, 6m2 or 10060 cm

Making the foundation

Of course, you can install polycarbonate garden shower cabins on an ordinary wooden grid, which will be installed on the posts, and all the water will flow directly onto the soil, but then by the end of summer unpleasant smells will appear on your site.

There is another option - to install a drain ladder on the slab foundation and divert sewage into a cesspool (also not the best option in terms of hygiene) or a septic tank, which will turn out to be somewhat more expensive, but it will meet all sanitary standards.

To do this, we first install the column foundation, although it can rather be called pile-stuffed - we take four segments of asbestos-cement (azeid) pipes with a cross section of 100-150 mm, approximately 60-70 cm long, and we dig them into the ground to a depth of 30 -40 cm, depending on the slope on the site.

After that, we fill the pipes with concrete (best of all, fine-grained) and for the fortress, you can stick them in the middle of a piece of reinforcement. Between them, in the area of the booth (no need for the locker room), we fill the stove with a slope of 1-1.5 cm per linear meter - water will flow down it.

At the bottom of this drain (at the base) should be equipped with drainage and a compost pit as a septic tank - note that the volume of the compost pit should be at least twice the capacity of the tank that you will use for bathing.

Instead of an inclined slab of concrete, you can equip any other waterproof layer - just pour the sand, screenings or rubble under the same slope and cover it with hydroglass glass, although this can also be an ordinary roofing material or a dense cellophane film.

Recommendation. It is not recommended to have a compost pit directly under a shower - water flowing there will mold, which will cause an unpleasant smell. It is better to equip it nearby, in an open place for the sun's rays.

We are going to a booth

The most convenient way is to make a frame from a wooden bar, in order to fix the polycarbonate sheets on it with self-tapping screws - this, of course, can be done on the metal profile frame, but there you will need to drill a hole for each fastener for the screw.

For risers and top trim, you can use a bar of 10,050 mm or even 70x50 mm, but this will not be enough for the lower binding - there you need to use at least 10,050 mm or even 1,550 mm - you should still take into account the weight of the water tank and the washable one person

After assembling the frame (wooden or metal), you will only have to cut and fasten polycarbonate for the shower cabin with screws on wood or metal - everything will depend on the frame profile. Self-tapping screws are best used with a press washer - they do not rust and press the sheet well.

In the upper photo you can see that the tank is under the arched ceiling - this feature allows you to use the booth in rainy weather.

Conclusion

As you can see, it is not so difficult to equip a good polycarbonate shower stall with your own hands, as it may seem at first glance. In addition, thanks to the material, it will look very modern (see also the article How to install semicircular showers).