Polymer sand well

In the construction of underground utilities (water supply, sewage), the durability and reliability of materials such as wells, pipelines, etc. play a large role. Also, an important role in private construction is played by the mass of mounted elements, especially reinforced concrete wells, since these are extra costs for special equipment, delivery, plus it is not always possible to use it, due to the constrained conditions of the construction site. An excellent alternative to the traditional reinforced concrete well is a polymer sandstone well, which is devoid of all these disadvantages.

Manufacturing

For the production of polymer-sand wells, sand is used as a filler, and composite polymers - as binders. As polymers, polyethylene is usually used. All components are mixed together and under the action of high temperature and pressure in special molds "baked". After this treatment, a very durable and slightly porous material is obtained.

Benefits

For a long time there was no alternative to reinforced concrete wells, although they had a lot of shortcomings, ranging from mass to fragile and very poor airtightness. In place of reinforced concrete comes a new material - polymer sanding, which has several advantages:

- Small weight in comparison with a reinforced concrete well. The weight of one element of a polymer sand well does not exceed 60 kg, while the mass of a reinforced concrete ring with a diameter of 1 m and a minimum height of 60 cm is 400 kg.

- High frost resistance. It can withstand about 500 cycles of freezing and thawing.

- Long service life. The well can be in the ground without loss of bearing capacity for up to 100 years.

- High strength. Can be installed on the roadway.

- Resistance to aggressive substances. Do not need external waterproofing, unlike reinforced concrete wells.

- Thanks to the tongue and groove system, the well construction is easily mounted without the use of cement-sand mortar.

- High hydrophobic properties. Water absorption does not exceed 0.03%.

The disadvantages of polymer-sand wells include their high cost and small range - today the industry produces wells with a diameter of 1 m.

Application and device

The scope of application of this type of wells is very wide:

- device of sewer system;

- drainage device;

- installation of water supply systems;

- arrangement of the caisson well.

Polymer sand well is not used for the device of the water supply well, since the polymers used for the production of wells have toxic properties - their direct contact with drinking water is unacceptable.

The device of a polymeric sand well is the following:

- bottom plate;

- wall rings;

- neck;

- Luke.

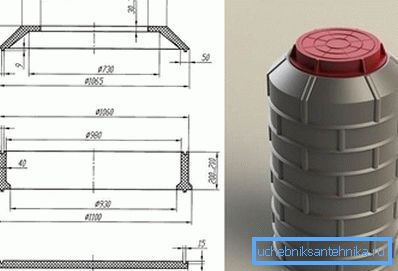

The bottom plate (base) is a disk with a diameter of 110 cm and a thickness of 3 cm, on the one hand the plate has a selected groove, the diameter of which coincides with the diameter of the ring.

The ring is a cylinder with a height of 20 cm, the outer diameter of which is 106 cm, and the inner diameter is 97 cm. The lower end of the ring has a ridge, and there is a groove on the upper end. The number of rings dialed depending on the depth of the well.

The neck has a truncated cone 15 cm high. The size of the lower diameter of the cone is equal to the diameter of the ring, and the outer diameter of the upper base is 74 cm, which is equal to the size of the hatch.

Installation of a well

The preparatory works for the installation of polymer-sand wells are the same as for the installation of a well of reinforced concrete elements. For a start, digging a ditch, if the depth of the excavation in sandy soils is more than 1.5 m, then you need to dig with slopes not less than 0.5 m. the following, and so on to the required height. The neck is installed on the final ring.

To completely seal the well, the joints should be coated with bitumen mastic during installation; such a well can be installed at a high level of groundwater, without fear of ingress of water inside.

The final stage of installation is cutting technological holes for communications. This can be done before installation or at the place. You can cut a hole using a standard crown of the desired diameter. The gap between the pipeline and the wall of the well sealed with mastic or sealant. After everything is assembled, the well is filled with soil that does not contain large stones, and the sinuses are carefully rammed.

Video

Watch a video about precast polymer sandwich pits. It provides answers to emerging questions: