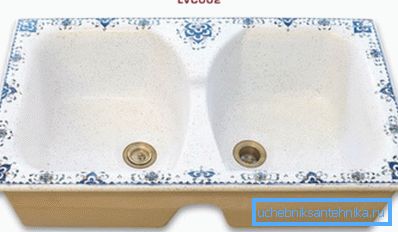

Porcelain sink - beauty of natural stone

Familiar to many of us, porcelain stoneware appeared in the 2nd half of the last century in Italy. Over the past decades, people have appreciated its high performance and attractive appearance.

Today, porcelain is used as a finishing material and for the manufacture of sanitary ware.

General requirements for ceramic granite sinks

Kitchen sinks made of porcelain stoneware, as well as kitchen sinks made of porcelain stoneware and other sanitary ware for the bathroom or toilet have become especially popular lately.

There are several general requirements that are put forward to the sinks, and other plumbing:

- the material should be hard enough, the material should carry light shocks without problems;

- the surface should be smooth, the material should not absorb liquids and change color;

- temperature differences sink should endure without cracking;

- Resistance to aggressive household chemicals, various cleaning products, alkalis, acids and other substances is especially important;

- the material must be environmentally friendly and not emit harmful substances. This requirement is especially important for kitchen sinks, because foodstuffs come into direct contact with its surface;

- the interior of the kitchen is also important, so when choosing you need to take into account the appearance (shape, color, etc.);

- it is desirable that the sink was silent.

All the listed requirements are fully consistent with the ceramic-granite sink. It is also important that the price of such shells remains at an acceptable level, you can choose a pretty model at a price of 5,000 rubles or more.

Learn more about artificial stone sinks.

Quite often, such models are called granite, although this is not entirely true. It will be correct to call this material an artificial stone, because it is prepared from a mineral filler and a binder (most often polymer). Nevertheless, in terms of operational properties, artificial stone is almost as good as natural.

The strengths and weaknesses of stoneware sinks

In addition to artificial granite, stainless steel, cast iron and even plastic can be used to produce, for example, kitchen sinks.

But when compared to porcelain stoneware, all the listed competitors gain:

- artificial granite is highly durable;

Note! Despite its high strength, it is possible to chipping an artificial stone upon impact. So, if the installation of the sink will be done by hand, then you need to avoid sharp blows to the sink as much as possible - you can easily break off a piece.

- this material does not absorb liquids, so the color of the shell will remain the same as it was when it was purchased. (of course, subject to timely cleaning);

- compared to stainless steel counterparts, porcelain stoneware models are characterized by absolute noiselessness;

- without problems can withstand temperatures of about 280-300? C;

- on sale you can find models that mimic such materials as marble, onyx, various types of granite, so that the appearance is at a height;

- Some manufacturers, seeking to attract customers, add to the mixture of ions of silver, Teflon. As a result, the sink also acquires disinfectant and dirt-repellent properties.

There are not so many disadvantages, except that:

- the complexity of transportation and installation is a direct consequence of the large weight;

- the need for regular cleaning, in more detail about how to clean the sink of porcelain, further in the article;

- Also, manufacturers do not recommend using powder cleaners to care for the sink, and metal scrapers are not recommended.

Rules for the care of a sink made of artificial stone

Despite the fact that the artificial stone is about 3 times stronger than the natural stone, you should not use powder cleaners and metal scrapers when cleaning. The fact is that microscopic scratches can form on the mirror surface of the sink, and then it will be very difficult to get rid of them.

Note! If you still could not avoid scratching, then the damaged place can be simply sanded. The surface will again be perfectly smooth.

It is much easier to clean it regularly to prevent dirt from entering the material. With regard to the choice of cleaning products, then there are special formulations for artificial stone. You can also pay attention to products containing hydrochloric acid, it is quite effectively removes all types of pollution.

Instructions for cleaning the sink is quite simple, you need:

- apply a cleaning agent to the surface and wait a couple of minutes;

- then the sink is wiped with a stiff brush or cloth, and the water jet finally removes dirt from the tap.

Note! If you need to get rid of scale, then the usual table vinegar will do.

It is a little about the production technology and composition of an artificial stone

Porcelain stoneware sinks are molded from a mixture containing a binder, dyes and aggregates, the total number of components can reach 16. It is necessary to include pure quartz sand, feldspar and clay. And clay is used most often illite - it is more plastic than kaolin, and a little lower refractoriness does not play any role for the sink.

Also, the mixture may include mineral aggregate (for example, marble chips) and dyes, which determine the appearance of the finished product. As an option, you can consider buying a glazed porcelain stoneware shell, due to savings on dyes achieved significant savings.

As for the technological process of production, it consists of the following stages:

- first, the components are ground in a huge drum;

- then a slip (a mixture of water and crushed clay, sand and other materials) is fed to the pool, where it is stored;

- the composition of the mixture is prepared and the casting of the sink or any other plumbing equipment in the mold is made;

- then the mold is removed, and the product is sent to the furnace, where at high temperature it acquires high strength characteristics;

- This is followed by quality control and shipment to the warehouse.

In conclusion

Porcelain stoneware sinks are an excellent substitute for nondescript stainless steel or plastic counterparts. Thanks to its excellent appearance, durability and performance, this “new thing” will perfectly fit into any interior (see also the article Ceramic sink: everything you need to know about it).

Not the least role is played by the low cost of such sinks. The video in this article proves the high performance properties of ceramic granite sinks.