Sewage clearing by hydrodynamic method: parameters, features

Hydrodynamic cleaning of sewage is a modern way of dealing with blockages of a pipeline of various origin. The method is characterized by high efficiency, safety and simplicity. We will tell what a hydrodynamic sewage treatment is.

Features of the method

Operating principle

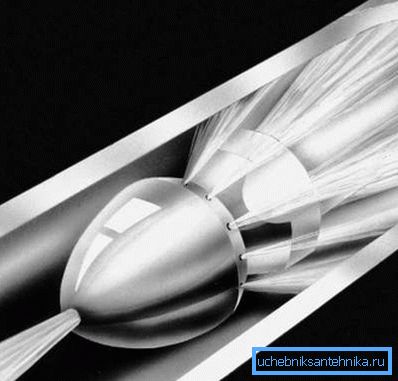

Hydrodynamic sewage cleaning is the effect of high-pressure water jets on blockages and deposits on pipe walls. To do this, a flexible high-pressure hose is introduced into the pipe, at the end of which a special nozzle with a system of nozzles is located, which form and direct the jets of a certain shape and intensity.

The front part of the nozzle has a sharp or rounded shape depending on the purpose. The bulk of the water is thrown back tangentially to the pipe walls. Thus, it is possible to wash off almost any deposits, in addition, the jets create jet thrust, which moves the sleeve with the nozzle into the interior of the pipeline.

Part of the water is thrown forward to facilitate the punching of blockages and congestion. Some types of nozzles can rotate for the best fight against fatty deposits and viscous raids.

Water can be cold and hot, the maximum heating can reach 140 degrees, since water is under pressure, it does not go into a state of steam. In addition, in some cases, they use not pure water, but a special chemical solution that helps to clean complex perennial traffic jams.

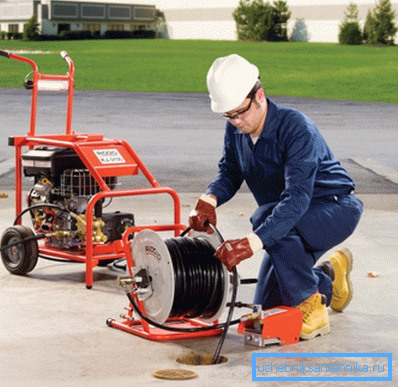

Note! To supply water with the necessary parameters of pressure and temperature, hydrodynamic machines are used to clean the sewers, which can have different sizes and performance.

To work with the house pipeline, a small unit is enough that fits in the trunk of a car.

Features and Benefits

For operation of the system, ordinary tap water is used. Pure cold water is most often used, however, if necessary, after diagnosing a blockage and making a cleaning map, it can be decided to heat the water and add certain chemicals.

Working pressure is usually about 150 atm. In some models, the pressure can reach 300 atm., But such installations are used for work on an industrial scale. The diameter of the pipes can be from 100 to 1500 mm.

Installations of water supply are equipped with high-pressure pumps running on electric or gasoline engines. The sleeve is most often made of a metal-plastic composition or polymer fabric, it allows you to quite successfully direct and manipulate the head. The maximum length of the sleeve is about 40 meters, but sometimes there are cars with a length of 100 meters or more.

Note! The equipment and the method itself are distinguished by high safety: the instruction allows working with any materials - cast iron, steel, plastic, metal-plastic and polymer compositions. The pressure is regulated, and the pressure is chosen so as not to harm the walls and seams of the pipeline.

Hydrodynamic cleaning of pipes has a number of unique advantages that have determined the popularity of the method among modern consumers:

- Cleaning takes place down to the base surface of the pipes., that is, dirt and plaque are completely removed. With mechanical or plunge processing of this degree of purification is impossible to achieve;

- A simple technology that does not require special knowledge or special skills of staff. Enough basic skills and responsibilities;

- High performance and speed of work. Clearing the usual domestic sewer blockage rarely takes more than an hour;

- The pressure of the water jets is such that they cut off any deposits and congestion. - fat, silt, salt, calcareous, corrosive, stone and other, as well as remove various organisms and plants;

- The impact of water under pressure is completely safe for the material of the pipe walls, their joints, welds and various threaded and extruded joints;

- Hydrotreating allows full restoration of the working gap of the pipeline and return it to a state close to the original. It is incomparably cheaper to replace pipes with new ones;

- The method allows working in remote and hard-to-reach areas of the water supply system.. In addition, the units are characterized by mobility and are most often installed on a self-propelled vehicle base;

- The equipment allows you to work successfully with frozen pipe sections and ice jams.

Note! Separately, it is necessary to single out such an advantage as the ability to simultaneously pierce traffic jams and remove garbage with water streams.

Scope of application

The method of hydrodynamic cleaning is used for pipes for the following purposes:

- Plumbing, both external and internal;

- Sewerage;

- Heating systems and heat exchangers;

- Wells and wells;

- Gutters;

- Drainage systems;

- Storm sewer.

Note! Buying a unit for work with your own hands does not make sense, since the price of services of a professional team is on average 200 - 300 rubles per linear meter with a car price of at least 700 dollars.

Conclusion

Cleaning pipes with high-pressure water is one of the most effective and safe ways to care for communications. The method allows both emergency and prophylactic use. The video in this article clearly shows the effectiveness and principle of operation of the high-pressure cleaning unit.