Sink 50х60 - the universal decision for kitchen

Choosing a sink for the kitchen is not an easy task, because besides the look and the material from which it is made, you also have to take into account the installation method. The simplest option can be considered as an overhead installation, but there are a couple of other important points of installation. The article deals with the surface mounting, its weaknesses and strengths compared with other types of installation.

What sinks are suitable for surface mounting

There are several types of moek.

For example, by type of material they can be divided into:

- plastic, the cheapest option - ordinary cast sinks, resemble a plastic basin with the only difference that they have a drain hole for connecting to the sewer. In some models there was a place for the holes for the mixer. Also available are more expensive acrylic models, reinforced with fiberglass;

- 500x600 mm washbasin can be considered a universal option. It can only be noted that some noisiness of such models, but low cost and durability outweigh this disadvantage;

- ceramogranitny sinks on properties practically do not differ from granite or marble sinks, except that the cost is several times less;

- cast iron enameled models could be called ideal from all points of view, if not for their fragility.

Also, classification can be made according to the shape, size, type of sink (single or double). All this must be considered when choosing the type of installation.

As for the surface mounting, the main thing is the shape of the shell. The fact is that the sink will simply be placed on a special cabinet (it is also a base), so it is desirable that its shape be geometrically correct. Otherwise, it will simply be more difficult to fabricate a frame for it and to achieve a tight fit of the sink to the upper belt of the frame.

Comparison of how to install a sink in the kitchen

You can select several different ways to install a sink in the kitchen:

- surface mounting - while the kitchen sink will require the construction of a separate pedestal under it. Its size is equal to the dimensions of the shell itself;

- mortise installation - while in the tabletop just cut a hole that follows the contour of the sink. Then the wash is inserted into it;

- under-table mounting - with this method of fastening the sink is under the table-top, from the point of view of tightness it is the best option;

- It is possible to single out such a method of placing the car wash, when it is literally just placed on a flat surface. An example is the installation of a designer stone sink - at the bottom, of course, there are holes for draining water, but on the whole the sink does not mask.

If we compare the listed installation methods, then the unprofitable installation can be considered as the leader in terms of ease of installation. True, there is also a flip side of the medal - on both sides of the pedestal it will not be possible to get rid of the cracks, so there is an increased risk that the wooden elements will simply become damp.

Mortise installation is a little more complicated, but the result is worth it. The sink looks much more profitable against the background of a solid tabletop. Since the shape of the wash does not matter in this case, it is possible to choose any model, including an asymmetric shape in the plan. The price of such a sink will be slightly higher than a simple square or rectangular.

Under-table placement allows almost 100% to ensure that water splashes do not fall under the countertop. The only seam between the side of the sink and the table top is reliably sealed.

Other methods of installation in the kitchen do not apply due to the fact that it is too inefficient use of free space. In the kitchen is very important.

An example of installation of a wall washer

For convenience, the process can be divided into 3 stages:

- measurements and assembly of underframe frame, its trimming;

- sink installation;

- its connection to the sewer.

What should be the frame under the sink

The requirement for the sub-base put forward the following:

- it should be tough and durable enough, for example, washing from a stone 450 600 mm is quite weighty, so that the cabinet should withstand its weight without problems;

- moisture should preferably not have a strong effect on the material;

- the cabinet under the kitchen sink should not have a back wall - this will facilitate its connection to the sewer;

- it is desirable to raise it above the floor level, and the gap between the bottom of the base and the floor can always be covered with a wooden plank.

With regard to the material used, for the cabinets under the invoice installation can be used:

- Chipboard - if you install a pair of transverse strips of material in the frame, the design will be quite rigid;

Note! In the manufacture of cabinets with their own hands, it is allowed to strengthen the joint of sheets of chipboard with metal corners from the inside.

- You can also use ordinary wooden planks. Of them simply going to frame, which is then sheathed with wood. And the appearance at height, and the strength of the structure is provided;

- plastic frames should be considered solely as an option to give. You can install a plastic sink on them and stop it on the street without fear that the material will be sodden. Under heavy enameled cast-iron or plastic stone washing is not suitable.

Assembly of the frame under the sink

Most errors are allowed when assembling the cabinets of chipboard. Moreover, these errors relate mostly to trifles, for example, chipboard sheets are not correctly connected, but as a result, this can reduce the strength of the structure.

Attention should be paid to such moments as:

- the correct cutting is of great importance, the cabinet for the kitchen sink 50x60 centimeters should have exactly the same dimensions;

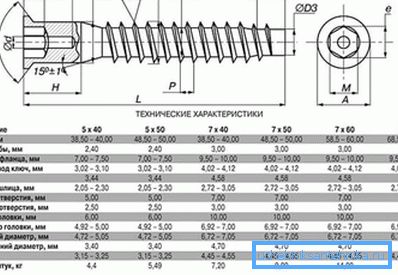

- For the connection of sheets, confirmatics must be used (they are also euro screws). Normal black screw will not work;

- constantly need to control the perpendicularity of the walls of the cabinet and the evenness of the upper surface.

More detailed assembly instructions are as follows:

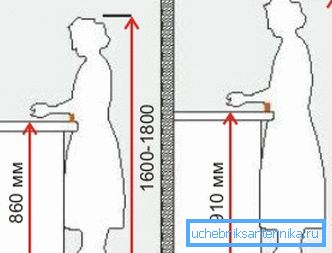

- cutting is performed. If the shape of the shell is geometrically correct, then this should not pose any particular problems. Before that, you need to estimate a convenient shell height - in this matter a lot depends on a person’s height, but usually a height of 0.85–1.0 m is sufficient;

Note! When selecting the optimum height of the sink, it is necessary to take into account its depth. For example, the same kitchen sink 50x60 centimeters, but of different depths, will require different installation heights.

- after this, the walls of the cabinet are directly connected. More details on the technology of confirmatory compounds are discussed below;

- a siphon is connected to the sink, this will simplify its connection to the sewage system after installation;

- the cabinet under the sink 50x60 is placed in the right place and you can install a sink on it.

The support of the elements of the cabinet by the confirmatists is good in that it is always possible to close their heads with pretty plastic plugs, and the strength of such a connection, while observing the technology, is quite high.

When using euro screws, you must adhere to the following rules:

- a hole must be drilled under the threaded part and under the keg;

- the depth of the hole must be at least equal to the length of the threaded part;

- when drilling the barrel hole (part of the euro screw between the head and the thread), you need to control the distance to the edge. The minimum distance depends on the thickness, for example, for a sheet with a thickness of 1.6 centimeters, you need to retreat from the edge of at least 0.8 cm.

Note! If this requirement is not observed, after the sheets are joined, we will most likely get an ugly bulge on the particle board.

The sink is installed using 4 special plastic mounts with an inclined slot for the screw. First, pretends to be the design position of the sink, then it moves a little forward, pretends to be the position of the plastic mounts.

Then the screws are screwed in, but not fully, the mount can move freely on them. It attaches to the bottom of the sink and shifts back so that the sink is in the correct position. After that, the screws turn to the end so that the sink is securely fastened.

The final stage can be considered the installation of the mixer and connect the sink to the sewer.

In conclusion

Kitchen sinks - one of the most important elements of the kitchen environment. Not only the appearance of the room, but also the convenience of using the kitchen as a whole depends on the correct selection and installation of the sink. The proposed material focuses mainly on the surface mounting method for the kitchen sink.

The video in this article can be considered a step-by-step instruction on how to install an invoice wash.