Sink consignment 60x60 cm stainless steel - the best option

In the premises intended for cooking, food and dishes are regularly washed, therefore it is necessary to create a comfortable place for these operations. The first step is to purchase a suitable design with a bowl.

When choosing attention should be paid not only to the shape of the product, but also to size.

The advantages of small-sized products

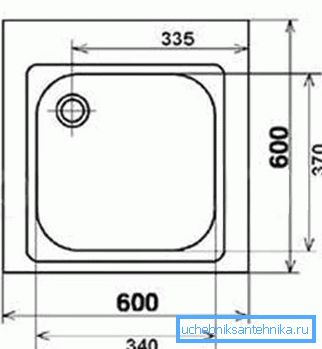

Laid on sink for kitchen 60x60 cm belongs to the category of compact plumbing devices. It is usually installed on a cabinet of appropriate dimensions, which has no upper part. Most often, products with such dimensions are used for small spaces where space saving plays a leading role.

The most significant advantages are presented below, so that the consumer can evaluate the effectiveness of this choice.

- The price of products is low, because the size of the structure depends on the consumption of certain materials.

- Small decor elements are easier to fit into the overall design, which is not true of massive objects.

- The 600 × 600 mm surface washer takes up little space, freeing up space for other kitchen appliances.

- It is much easier to clean products of this size than in the case of bulky products.

Addition! The installation process usually takes place in fairly comfortable conditions, since the need to work with large parts is eliminated. In this regard, the speed of installation increases.

About popular manufacturing material

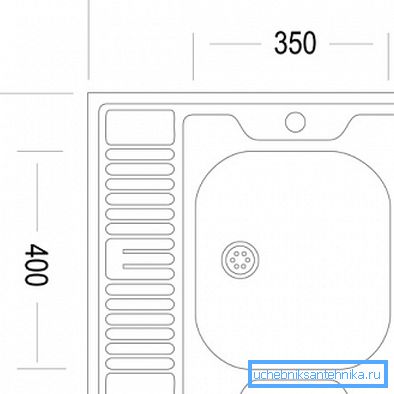

Mostly, surface-mounted sinks are made from stainless steel, although other materials may occur in certain situations. Typically, an enterprise creates a lid of a certain size, the bowl of which can take any shape. Near it, as a rule, a little space is left for drying.

The alloy acquires resistance to moisture due to the addition of a special component - chromium. For the operation of products under normal conditions, this substance must be contained in an amount of more than 13 percent. Anti-corrosion characteristics are due to the fact that a thin layer of insoluble oxides is formed outside.

The use of material for this type of product is due to its high strength. On the surface of stainless steel sinks, you can place kitchen utensils and products without fear of damage. Although strong shots with sharp objects can lead to deformation.

A set of requirements

Ideally, a 60-60-mm washing invoice should meet certain parameters that facilitate operation.

The main requirements for the design are given below, so that the consumer can pay attention to the most important points by making the right choice.

- The depth of the bowl is of no small importance, since convenience in work depends on this indicator. The best is the distance from the top edge to the bottom from 160 to 200 mm, which is explained by a sufficient capacity under normal operating conditions. Too deep a capacity can create discomfort when used.

- The thickness of the steel should not be less than 0.4 mm, but this is the minimum acceptable value. With an increase in this parameter, product quality increases significantly. Products are made by welding individual elements or by stamping. In the first case, it is possible to produce the deepest washes, but not all manufacturers can grind the seam well.

Note! The presence of drying is not a prerequisite, but welcome. A small platform for dishes and food can be located both on the right and on the left.

Installation work

The installation process is quite simple, so it can be done quite easily with your own hands, but first you need to learn the instructions, allowing you to take into account many different nuances. More complete information about the installation allows to make a high-quality installation.

The basis for the products

Surface wash is installed on the finished frame, which can be made from any material. Most often purchased a special cabinet, the dimensions of which correspond to the dimensions of stainless steel products. However, if necessary, the base can be made independently of chipboard sheets.

The floor cabinet is a fairly simple structure, which consists of side walls, bottom and doors. The width of the sheets should be 60 cm. As for the height, it can vary depending on the needs. The elements are connected to each other through wooden pins or furniture screws.

Certain difficulties are caused by the installation of doors, in the manufacture of which accuracy is important. If you make even a small mistake, they simply will not close. Special attention should be paid to the location of the loop. Each door should be hinged on two hinges.

Initially, the main frame is assembled from the side walls, after which the bottom is inserted and fixed in a horizontal position. When assembling the base from the front side, a 10 cm wide jumper is installed. It is necessary to hold the surface wash. The lower part will be securely connected by the lower plane.

Car wash mount

After the acquisition or independent construction of the supporting structure for the location of the product, you can proceed to the installation process, which consists in fixing the cover to the base.

In the course of work used fasteners with oblique slits.

- First of all, the sink fits into a convenient place to work.. Tools are being prepared: adjustable wrench, drill, pliers, tape measure, a set of screwdrivers and some other devices.

- A siphon with a thick gasket is attached to the drain hole.. Before that, it should be assembled. The nozzle joins the bottle part so that the nut presses the exit opening.

- Installation of the mixer is done immediately, otherwise the process can become very complicated.. The case is inserted into a special socket. On the inside, a gasket is put on and the fastening nut is tightened.

- Pre-marking for fasteners is applied on the surface of the side walls. Details are applied to the planes, after which the marks are left with a pencil.

- At 5 mm above the lines, blind holes are made into which the screws are screwed. Fasteners are installed on them. The height of these elements should be the same.

- The ends of the side walls are lubricated with silicone. In this case, it will be possible to protect the material from moisture, which means that its service life will increase significantly.

- Sink with the installed mixer and siphon inserted directly into the frame. The tops of the screws should fall into the holes. The lid is shifted toward the wall to lock in one position.

- At the finish, the flexible hoses of the water supply system are connected to the mixer, and the siphon is connected to the branch pipe of the sewer system. After completion of the work is performed testing.

Attention! Sink in the form of a cover cover may have additional fasteners, which are massive bars that are installed on the back side. This option is acceptable if the mass of the product is high.

Additional recommendations

- With self-made cabinets, particle boards can be glued over with a plastic film to create a decorative coating. In addition, it protects the material from external influences.

- Cutting boards of wood chips is desirable to produce an electric jigsaw, equipped with a fine tooth file. In this case, the most accurate cutting is provided.

- It is recommended to use four-hinge hinges for doors, as they fall into the category of universal ones. They are able to carry substantial loads.

- For sealing, you can purchase an inexpensive silicone rubber based product. In this case, resistance to ultraviolet radiation and rapid temperature changes are not required.

- It is best to immediately connect flexible hoses to the installed mixer in order to simplify the connection to cold and hot water. It only remains to tighten the two nuts.

- It is advisable to install a single-lever faucet with a lever, as it fits perfectly to the conditions of the kitchen room. The accuracy of the temperature setting in this case is not very important.

- If the space below is limited, it is recommended to use a corrugated siphon to connect to the drain hole. The special clamp prevents the tube from straightening.

- Sink should be installed in line with the stove to the cooking process took place in a comfortable environment. At the same time the distance between them should not be less than 60 cm.

- The drying zone can be located both on the left and on the right. However, the choice will depend on the final placement of the main elements and preferences of the owner of the dwelling.

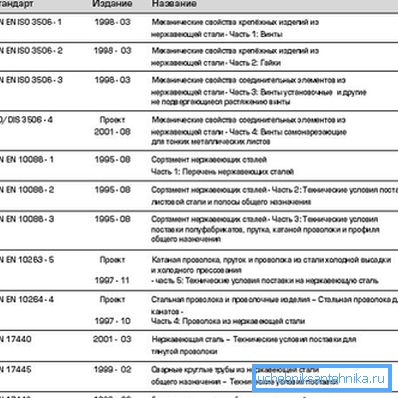

State standard

Technical conditions for product quality are set out in paragraphs of GOST 50851-96. The designation in the technical documentation is carried out using letters that define the type of product and its standard. Below is a clear example of the symbol - sink MNTs GOST 50851-96.

In the manufacture of the bottom of the product should have a bias towards the drain hole, ensuring complete removal of water. On the invisible part of the tank, a noise-absorbing coating is applied without fail. As for the visible plane, it should be well polished. Roughness more than 0.32 microns is not allowed.

The manufacturer is obliged to guarantee the compliance of structures with the requirements of the state standard under the conditions of storage and transportation. The warranty period is 2 years from the date of commissioning or sale of the object, but not more than 30 months from the date of shipment by the manufacturer.

The tolerances of the shape and flatness of a given surface of products should not be greater than the values specified in the table.

| Cross and longitudinal sides | 2 mm |

| The shape of the specified surface | 0.5 mm |

| Side walls, transition radius and bottom | 0.1 mm |

Note! Products of this type should be made of thin stainless steel suitable for polishing and stamping. The list of recommended grades of raw materials is given in the appendix GOST 50851-96.

As a conclusion

The above information gives an idea about stainless steel sinks, which are classified as small. Sizes of 6060 mm allow to successfully implement the design in the interior of small rooms.

The video in this article will help you become better acquainted with the products.