Sound insulation of sewer pipes: how to ensure peace and

How often did the noise of water streaming down the drain riser cause you discomfort? Are you ready to put up with this phenomenon? What is needed so that the peace and quiet of your home is not disturbed by the drain of the neighbor's toilet?

Will help ordinary sound insulation of sewer pipes, the arrangement of which does not require special skills and expensive materials.

Causes of noise

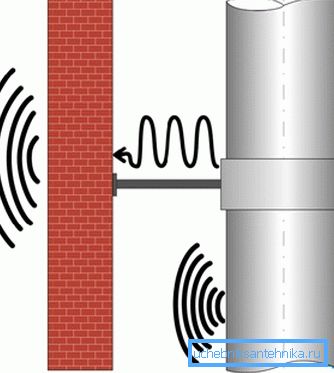

Unpleasant sounds in a sewer pipe arise due to its vibration.

And these fluctuations, in turn, are due to the following reasons:

- high rate of fluid flow (more than provided for operational characteristics of parts of the drainage network);

- water leaks from taps;

- a decrease in the internal diameter of the sewer pipe due to the accumulation of various deposits on its walls;

- the presence of internal defects of certain parts of the sewer system;

- poor attachment of the pipeline to the wall or floor.

Factors that affect the presence or absence of noise:

| Cause | Description |

| Mass details | The thicker the walls of a sewer pipe, the less noise the water flowing through it makes. |

| Material | Nowadays, PVC pipes are widely used for the manufacture of sewers. Unlike cast iron, they practically do not absorb noise, therefore they require additional sound insulation. |

| Mounting features | A central riser passing through the rooms of an apartment can cause a lot of noise. It is better when all pipelines are hidden in walls or floors (this should be provided at the design stage). Also, the details of the sewer network can be laid in special sleeves that reduce noise. |

| Compactor | Often during the installation of pipes used construction foam, which absolutely does not absorb noise. For noise insulation, you need to use polyethylene foam. |

Tip! Best of all, when measures to rid the sewer system from noise were taken at the design stage. Otherwise, it remains only to use special insulation materials.

Ways to get rid of noise

Using special parts

Modern industry produces plastic sewer pipes, which have good sound insulation characteristics.

This is achieved by adding a special mineral powder to them:

- microcalcite (marble powder or flour);

- chalk or limestone;

- dolomite.

Externally, these products are distinguished by thickened walls (like in cast-iron pipes), white color and marking with lines of two colors - red and green, applied along the part.

Remember that quality pipes are distinguished by the following features:

- presence of the name and logo of the manufacturer, as well as details of the plant that manufactured the pipes;

- an indication of the amount by which the noise is attenuated (in decibels).

The sound absorption performance of these pipes is comparable to cast iron products. Disadvantages - high price and short service life (no more than 20 years).

Freedom from infrasound

This term refers to oscillations with a frequency of up to 20 MHz that are not caught by the human ear, but have an extremely negative effect on the psyche. Sewer pipes can create resonant oscillations that reach the length of the infrasonic wave throughout the whole building.

To avoid the problem being described, you should:

- replace one of the elements of the riser, leaving untouched concrete parts in the floors;

- damping the entire plastic element of the vertical drain system.

In the first case, during repair, only the element passing in the apartment is replaced, and the crosses embedded in the ceiling and floor plates are left untouched.

To improve the permeability of the old elements, they are treated with household tools for cleaning pipes. To achieve the complete removal of plaque is not necessary. This layer will soften and wash off by itself during operation of the drain system.

The considered method of getting rid of infrasonic vibrations has the following advantages:

- repair work does not affect the capital structure;

- the replacement of vertical risers will not require the involvement of qualified specialists and can be made independently;

- estimated cost of construction is reduced - no need to purchase and install crosses.

As a result, the sounding plastic pipe will be divided into shorter sections by cast-iron elements. This will avoid the formation of resonant vibrations and change the very nature of the sound, making it harmless to the health of people living in the house.

Most likely, after such a replacement, no additional sound insulation measures will be required.

But what if the entire sewer system of the building is made of plastic?

In this case, the instruction is completely different: you need to isolate the details of the sewer network from the structural elements of the building:

- concrete interfloor overlappings - a special polyethylene cup is used;

- vertical surfaces - a special soundproofing collar is required.

Note! Polyethylene itself is a soft material, which is almost as good as cast iron in its soundproofing properties. To achieve greater effect, the design of the insulating glass is complemented by polyurethane foam.

Arrangement of such a node does not require the purchase and installation of special glasses. It is enough to buy polyethylene pipes of larger diameter, cut them and insert foam rubber inside. Through this structure, mounted in the ceiling, the riser pipe is passed.

Remember that polyethylene itself is not suitable for constructing an individual sewer network. The best characteristics have PVC pipes.

If the riser is already installed, the installation of the glass is as follows:

- polyethylene pipe is cut in half along;

- polyurethane foam wraps part of the riser passing through the overlap;

- two separate halves are inserted in the same place and fastened with clamps, and then - with cement mortar.

Tip! Do not replace polyurethane foam with foam, mineral wool or foam. They absolutely do not help for sound insulation.

Sound insulation clamps can be made independently. To do this, under the usual mounting clamp you need to put a piece of rubber.

Isolation from audible sounds

Unlike infrasound, the audible rustling and gurgling does not harm the human body, with the exception of its nervous system. You can get rid of this phenomenon with the help of polyurethane foam or foam sheath. It should be installed both on the central riser and on other parts of the sewer network.

Foam rubber is a bit more expensive, but it allows you to close rounded sections and sections of the pipeline, laid in inconvenient places. Polyfoam is easier to install, but in this case it is important that there is a gap of the right size between the pipe and the wall.

The process of sound insulation using polyurethane foam is simple:

- purchased material is cut into pieces of the desired length and width;

- these elements are wrapped around the pipes and secured with construction adhesive tape;

- It is necessary to close the canvas tightly so that no unpleasant vibrations occur.

Conclusion

Having finished all the work, you can be sure that the unpleasant sounds will never disturb you again. For more information about the work on sound insulation drain system, you can learn from the video in this article.