Stone washers: features of structures made from natural and

Stone sinks look amazing in the kitchen, perfectly harmonizing with countertops made of similar material. In addition to the attractive appearance, they also have high practicality.

In this article we will look at their qualities and varieties in more detail.

A natural stone

Sinks made of natural stone are created by grinding a single piece of rock in the desired shape. As a result, due to the need to use natural material and the complexity of the production process, the price of finished products is very high, but they have unique aesthetics and high reliability. In this case, the raw material can be used differently:

Kinds

| Title | pros | Minuses |

| Granite and basalt | The hardness of this material on the Mohs scale is eight, which guarantees the sink made of it is incredibly high resistance to mechanical stress, acids and temperature changes. | A very large weight, for example, a bowl 600 mm wide will weigh at least eighty kilograms. |

| Marble |

|

|

| Onyx |

| Very high cost, as it refers to semiprecious stones |

Tip: when caring for marble and onyx shells, stop using abrasive cleaners, as they can damage their surface.

Impregnation

The high level of porosity causes great inconvenience when using sinks made of natural stone, so once a year their surface must be treated with a special water-repellent agent, which covers the pores with a film.

Fake diamond

This material is created from:

- Mineral filler, betraying the desired structure of the finished product;

- Pigments responsible for the final color;

- Acrylic resin, which binds everything together.

Manufacturing washing of artificial stone is performed using special equipment at high temperatures.

Kinds

| Title | Description |

| Acrylic stone | The white clay crushed into powder, which is part of the porcelain, is used as a filler. It can have both monophonic coloring, and to imitate the majority of representatives of a natural stone. |

| Cast marble or artificial granite | This option is filled with a crumb of marble, quartz or granite, which gives its texture a characteristic point pattern. Thanks to the addition of pigments, it is also able to imitate any minerals. |

Now let's see what kind of washing of an artificial stone has pros and cons.

Character traits

The main advantages of washing of artificial stone:

- No pores. This is the most significant difference from products made from natural materials. Fluid, fat, acids and other substances that can spoil the appearance or even destroy the shell structure do not penetrate into their structure.

- Enough simple repairing a wash made of artificial stone with your own hands in case of chipping or other minor damage.. Glue and grinding perfectly cope with the restoration.

- UV resistance. The saturation of the color does not change throughout the entire life of the product.

- Durability. With proper care, such a sink will serve you for at least ten years, while maintaining its aesthetics.

- A wide range of shapes and colors. Almost any construction can be poured from the material under consideration, and the addition of the necessary pigments will color it in any color scheme.

Also worth mentioning are some of the drawbacks:

- Other tactile sensations. When you touch this material, it becomes clear that it is still not a natural element, but a polymer.

- Fear of high temperatures. The touch of a hot frying pan or pan can deform the surface of the sink.

Drilling

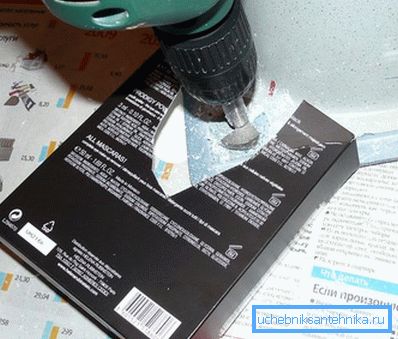

We should also touch upon the question of how and how to drill a sink of artificial stone? Because sometimes there are models without a hole for the mixer, and then it needs to be done independently.

The process is performed in the following way:

- Take a drill and a mill with a diameter of 35 mm.

- We mark the future of the hole on the back of the sink.

- We place the bowl on the waste board, having previously placed a newspaper so as not to scratch the front surface.

Tip: it is recommended to additionally substitute an empty box for collecting small chips, as it will be quite a lot in the process.

- We bring the tool and begin to drill slowly. We continue until wood chips signify the passage of the side of the bowl through.

Conclusion

Sinks can be made of both natural and artificial stone. Both materials have their strengths and weaknesses.

The video in this article will introduce additional materials. Choose only the best for your home!