Summer showers of film, profiled sheets, polycarbonate

In the summer, water procedures can be carried out directly on the street, but this will require at least an uncomplicated protective structure. When the summer shower is made to give your own hands, cheapness and ease of installation come to the fore. In this connection, the simplest but effective materials should be used in the course of the work.

The merits of summer boxing

The main structure is usually a lightweight construction that is small in size. It has some advantages when compared with stationary facilities designed for showering.

More about the positive qualities are described below.

- The low price of the facilities allows them to be arranged without serious damage to the family budget.

- If necessary, such structures can be easily moved to another place.

- Simple installation technology allows you to build a lightweight construction with your own hands.

- The construction process does not take much time, which cannot be said about massive buildings of this type.

Note! Although toilet and shower cabins for summer houses, intended for summer use, are very popular, they cannot be compared with stationary counterparts in terms of comfort and reliability.

Main options

No matter what materials the structure is made of, it must withstand the weight of the tank with water and be stable even with strong gusts of wind. To achieve good strength characteristics allows a metal or wooden frame. Barrier functions are performed by sheets of a particular material.

Film construction

The simplest option is to cover the framework of metal pipes with an opaque film. Vertical elements are installed at the corners, which are connected by bridges at the top and bottom. Parts are fastened by welding or with bolts.

The film is glued to the support posts with adhesive composition. It stretches along the perimeter of the building, after which a cut is made to enter. 15-20 cm are usually receded from the ground. However, if necessary, the side parts can be closed completely.

The construction of the profiled sheets

When the summer shower is arranged with the hands, the professional flooring is very often applied. With it, you can create a fairly strong and durable structure of the portable type. Its service life will depend on the quality of the acquired profiled sheets.

At the first stage, the frame is made of metal corners. Vertical elements are connected by horizontal bridges on the top and bottom. Additionally, you can install transverse corners to improve rigidity.

Sheets of the base material are fixed to the horizontal crossbars. For this, a hole is drilled into which a screw with a rubber seal is twisted. The corners are usually sealed with end strips so that the appearance of the finished structure is more aesthetic.

Polycarbonate Cab

Quite often, when building light objects, polycarbonate is used, which is a colorless plastic. Shower cabins and toilets for the garden are very aesthetic. This material can have different colors, which gives a lot of variations for the design.

The same metal frame or wooden base of the bars can act as a supporting part. In the second case, elements with a cross section of at least 10,050 mm are usually used. However, their final dimensions will depend on the tank dimensions and operating conditions.

If a shower cabin for a summer shower will be arranged from polycarbonate, then it is recommended to familiarize yourself with the rules for attaching the material to the base.

- The edge of the panels on the long side must necessarily lie on the bearing supports.

- If the dimensions of the structure exceed the width of the sheet, then when installing, connecting profiles are used.

- The material fragments should be positioned so that the internal cells are in a vertical position, providing a stack of condensate.

- Before installation, the ends of the panels must be glued with aluminum tape.

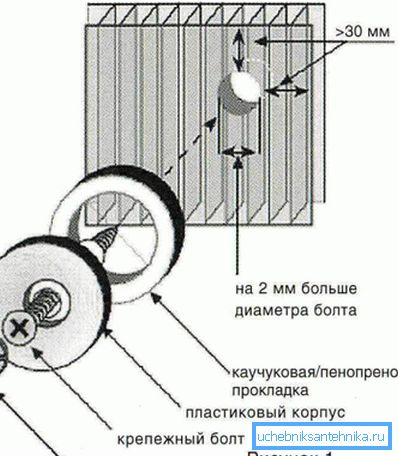

- Holes are made in the sheets for fixation, the diameter of which should be about 1-2 mm larger.

- After screwing the fasteners, you must close them with the protective caps that are supplied.

Note! Country-style shower cubicles and toilets made using wooden frames should be installed on the support tiles of reinforced concrete or other suitable materials.

Additional Information

- Water tank is recommended to install on the upper part of the frame, so that it forms a kind of roof. It is not necessary to arrange roofing flooring at all.

- Inside it is necessary to dig a shallow pit for water flow. On top of it you can put a special lattice of wooden bars and a polished board.

- For various accessories you can make a small shelf, securing it to one of the support posts. Fastening to the fence material is not recommended.

- When installing a watering can in the tank for a shower cabin, a hole is drilled. The device itself is inserted directly into it. The nuts are tightened from inside the tank. A rubber gasket is inserted for sealing.

Final part

Some individual developers are thinking about how to arrange a shower and toilet together. To do this, you need to increase the size of the structure by creating two branches at once. Other useful information regarding this topic is presented in the video in this article.