The frame for the shower tray: reliable support for our

When assembling a shower cabin with our own hands, we often face problems caused by poor quality components. And since the frame for the pallet is one of the most important elements of the whole structure, increased demands are made on its reliability.

Below we will tell you what you should pay attention to when purchasing a pallet frame, and also give a number of tips on how to make and install it yourself.

Frame specifications

Purpose and construction

The shower tray is a wide and relatively shallow container that is used to collect the flowing water and redirect it to the sewer drain. At the same time, a considerable area of the pallet, together with a small thickness of the material from which it is made, significantly complicates its use. Under load, the bottom bends, which leads to the deformation of the whole structure, as well as to the destruction of the anti-corrosive coating.

In addition, to ensure effective drainage, the pan must be installed in such a way that the drain hole is located above the entrance to the sewer riser. Accordingly, it is necessary to raise it above the floor level by about 100 mm, which is impossible to do without additional devices.

Such a device is the frame.

- First of all, it provides the pallet with the necessary support. Depending on the configuration, the frame can be located either only around the perimeter, or else under the bottom. The second option is more preferable especially for wide models: transverse reinforcing ribs give the desired stability.

- Secondly, frame legs allow you to raise the pallet above the floor to the desired height. At the same time, the mass of the structure increases slightly, which means that the load on the floors does not increase either, which is very important when equipping sanitary facilities in buildings made of lightweight materials.

- Thirdly, the design of most frames allows you to adjust the length of the legs. Thanks to this, we can quickly align the pallet on a plane, which is a prerequisite for the effective use of the shower.

Note! The shower stall must stand perfectly even, otherwise there will be problems with the discharge of water, and the doors in the rails will start to get stuck as a result of a skew. When installing frameless pallets, alignment is performed by pouring a tie on the selected area.

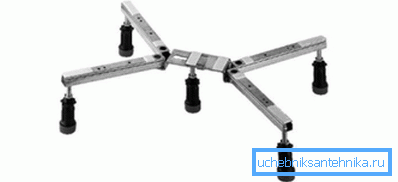

The design of such devices is quite simple:

- The basis is made up of several steel strips, connected either by welding or using angle brackets.

- At the ends of the slats and at the intersections, threaded holes are made into which sufficiently thick (10 mm and more) screws are installed.

- On the ends of the screws are screwed legs made of durable plastic. Inside the legs are also threaded, which allows you to adjust the position of the frame.

Recommendations for selection

Despite the fact that the price of such products is relatively small, they must be chosen very carefully. This is due to the fact that they perform a very important function: if the frame breaks, then its replacement will be associated with very serious labor costs, since the cabin will have to be dismantled almost completely.

Choosing a model, you need to pay attention to the following nuances:

- The first is the configuration of the support beams. It is desirable that they are located not around the perimeter of the pallet, but under its base. So the load that a person stands on the bottom will be distributed more evenly.

- Pipe thickness is also a very important factor. It is best to purchase models made from a shaped tube of at least 20x40 mm: such ones will not bend.

- Pay attention to the quality of the metal. It is very good if all the parts are covered with anti-corrosion paint: so we will be sure that even in conditions of high humidity the structure will not rust.

Tip! Particular attention is paid to the quality of processing welds, because here rust appears first. If there is even the slightest doubt, before installing it is worth treating problem areas with a protective compound again.

- Finally, you should inspect the legs and their attachment points. The parts must be screwed tight enough, but without undue effort, and on the supports there should be no cracks or other defects.

Fabrication and installation

How to make a frame

As a rule, we acquire supporting structures together with the shower tray itself. Ideally, both parts should be made by the same manufacturer - so the coincidence of sizes will be as accurate as possible.

However, sometimes it is quite difficult to find a suitable product, or the model you need is unreasonably expensive. In this case, it is possible to make the frame yourself.

For the manufacture we will need:

- Welding machine.

- Bulgarian with a cutting wheel on steel.

- Drill and drills of different diameters.

- Taps for cutting internal thread.

- Steel profile pipes (square 40 x 40 mm or rectangular 20 x 40 mm).

- Plastic nozzles on the legs.

- Steel rods with thread.

We perform the work as follows:

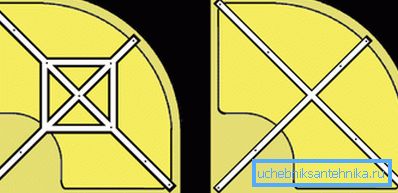

- To begin with we create the drawing of our future design. If we need a frame under the shower 90x90 cm, then the easiest way to make a cross-shaped support with dimensions of about 80x80 cm with reinforcing inserts.

- From the pipe we cut off the fragments of the required length and carefully clean them from rust.

- We put the blanks on the welding table and weld them, making sure that they are placed strictly horizontally. It is very important to control the absence of deviations in the case when we make an unregulated framework.

- If you are not skilled in welding, the parts can be bolted together. It should be remembered that the elements will be in different planes.

- Legs - the most difficult. For simple construction, it is enough to weld the bottom at an angle of 900 short lengths of profile pipe. If we need height adjustment, then in the pipes we drill holes in which we cut the threads, and then we twist the screws.

- We put plugs on the ends of the legs or twist adjustable plastic supports.

- All weld seams are carefully cleaned, and then we process the obtained part with anti-corrosion paint.

How to install the pallet on the frame

The process of installing the pallet on the frame (it does not matter, factory-made or homemade) does not present any difficulty:

- If there are mounting holes or special eyelets on the bottom of the pallet, then turn it over and fix the frame on the bottom with screws. Otherwise, the pallet will need to simply lay on a support, sometimes - with the use of sealant.

- Next, install the frame legs on the selected area of the floor. The surface should be as leveled and as clean as possible.

- Using a wrench, rotate the adjustment screws on the legs until the pan is installed perfectly flat. The process is controlled by one or several levels.

- After the installation is completed, we install decorative strips on the side supports of the pallet. In homemade designs for this purpose, you can pre-make several mounting holes.

Conclusion

As you can see, the above instruction is simple enough for self-implementation. Of course, it is more difficult to make a frame for a pallet than simply to use ready-made, but if necessary, this task can be done well.

For a more detailed study of the techniques described it is worth watching the video in this article.