The mechanism of the toilet bowl and its typical problems

In this article we have to get acquainted with how the drain tank is arranged. We will study the device of outdated and modern designs. In addition, we will address the typical problems of the mechanisms of the tank.

So go.

List of nodes

It is more than small.

- The filling mechanism for the toilet bowl (also known as the filling valve) is used for the dosed filling of the tank. When draining it opens; when rising to a certain level of water it closes the flow.

- The mechanism for flushing the toilet bowl (drain valve) is responsible, respectively, for draining. His task - after pressing a button, lever or jerk of the chain to expend the entire volume of water at maximum speed.

By the way: the so-called double drain mechanisms in one of the modes allow you to spend only a fraction of the volume of the tank, thereby saving water.

- Tank coupling unit with a shelf must ensure tightness when draining. Actually, in modern compacts, this function is assigned to an annular cuff of soft rubber.

Inlet valve

Brass with a beam

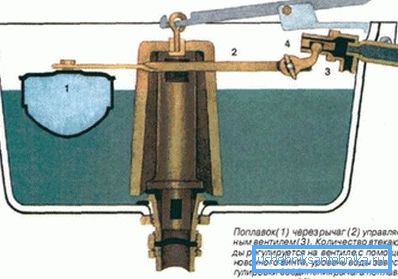

The oldest structurally, but used to this day, the filling mechanism for the toilet is a brass valve with a barrel, a yoke, a float and a rubber gasket.

The principle of its operation can be easily understood by disassembling this device:

- When the water level rises, the pop-up float pulls the long arm of the rocker up, while pressing the keg with a gasket to the conical nozzle and shutting off the water.

- When draining the float is lowered, and the barrel opens the nozzle.

Such a simple scheme, however, has several specific problems.

| Description of the problem | Cause | Elimination |

| No water enters tank | Nozzle clogged with sand or scale | Remove the pin, remove the yoke, remove the keg, clean the nozzle with wire |

| The valve does not block the water | Gasket lost elasticity | Bend the rocker; if it does not help, turn it over or replace the gasket |

| Rubbed the pin holding the yoke | Replace the stud with a piece of thick copper wire |

Plastic with a yoke

Due to the cheaper plastic compared to brass, the price of this type of valve is somewhat lower.

The design, however, has undergone a minimal amount of change.

- The adjustment of the rocker arm is not carried out by its forced deformation, but by the adjusting screw.

- Optionally added overturning float. When a certain water level is reached, he abruptly changes his position, thereby blocking the water, not gradually, but instantly.

To the above problems of the old mechanism were added related to the low mechanical strength of plastic. Now, as a rule, the stud does not fray and does not break down with rust, but gradually widens the holes in the valve body and falls out of them. Instructions for resolving this problem are, alas, reduced to replacing the entire valve.

With float guide

The modern float mechanism for a toilet bowl can get the most various forms and constructive executions. The key difference from the usual products from the Soviet Union is that the float moves along a vertical guide.

What are the advantages of such a decision:

- The fill valve takes up minimal space in the toilet.

- The displacement of the float in the horizontal plane is impossible. If so - the float can no longer interfere with the operation of the drain valve.

Adjustment of the float level, at which the water overlaps, is carried out by a screw mechanism. High-quality silicone pads have been around for decades. The only problem remains sand blocking the valve, which is treated by its disassembly and washing.

By the way: installing a coarse filter after the valve will fix the problem once and for all. But it is better not to install filters sold with valves: they have too thin grids and quickly become clogged with debris that the valve lets through without complications.

Drain valve

What could be the mechanism for flushing the toilet bowl?

Cast iron bell

These products were used in domestic overhead tanks at least from the first post-war years. A massive cast-iron valve on the lever resting on the edge of the tank was responsible for the discharge. Raising a valve attached to a lever by a chain opened the way for water; the rest of the water from the tank was sucked out by the vacuum created in the discharge pipe through the U-shaped overflow.

The typical problem of the bell is only one - the loss of gasket elasticity. Microporous rubber is used to replace the gasket. Unfortunately, the youngest models of this trouble-free design are already almost half a century old; erosion and lime deposits have practically taken them out of service.

Corrugated

This plastic misunderstanding changed the bell in the 70s of the last century. The corrugation tilted at a tug on the rope and again, due to the vacuum in the drain pipe, it sucked all the water from the tank.

This mechanism to flush the toilet was a flawed structure initially: its work is associated with the deformation of plastic. Liming its surface with water reduced the already small resource of corrugations to two years or less.

Pear

The pear, which was equipped with both the top tanks and the first compacts, became a more sensible solution. The rubber hemisphere walked along the guides and was raised with a lever or handle that went through the tank lid.

The main problem of the first sets of fittings with pears was the corrosion of steel bolts that attached the saddle to the tank body. Slightly less often the stock collapsed or the pear itself lost its elasticity. Do-it-yourself repair of fittings was reduced to the replacement of a defective item or, which was much more sensible, a complete set: its service-free life rarely exceeded 5-7 years.

A modern mechanism for flushing water in the toilet also often includes a pear; however, in it, unlike its predecessors, almost no metal parts are used. The pear is worn on a hollow polymer rod, which at the same time performs the function of overflow, and is lifted by a handle, towering above the tank lid.

Plastic bell

Simultaneously with pears in cheap plastic tanks, for a while, a mechanism was used with a plastic bell-float, worn on a cylindrical drain. When you press the button, the bell was sinking, displacing water; while it fell into the overflow and due to the dilution in the drain emptied the tank.

The design was extremely inconvenient to use, because it worked at a strictly defined level of water in the tank. The change in pressure in the aqueduct in combination with the then-popular floats with brass rocker significantly influenced this level.

Modern plums

A typical locking mechanism for the toilet, which are equipped with modern imported tanks, is a vertical plastic column. The cavity inside the column is an overflow; water is blocked by an annular gasket, worn on a hollow rod.

As a rule, drain mechanisms allow to regulate:

- Intensity of discharge due to setting the maximum distance between the seat and the gasket.

- Overflow level.

- In systems with double discharge - water consumption when pressing a button that uses part of the contents of the tank to drain.

The only typical construction problem is the gasket. For 5-8 years, it loses its elasticity and needs to be replaced. Fortunately, it is easy to purchase separately from the valve.

Pair of tank and toilet bowl

In modern toilet bowls with a molded shelf, an annular gasket serves indefinitely and does not create problems. The only design that deserves mentioning is a toilet with a separate shelf of the domestic sample.

The list of problems that it creates to the owner is quite impressive:

- Corrosion of fixing bolts.

- Chip shelves when pressed.

- Chip fixing ears toilet.

- Loss of elasticity of the oval cuff between the tank and the shelf.

- Torn conical cuff under the shelf.

A potential buyer can be given only one piece of advice: after seeing such a kit, move away from it as far as possible.

Conclusion

Of course, in one small material it is impossible to describe all the tank designs produced in the last decades. With some solutions that we have not touched, the reader will be introduced to the video in this article.

Successes!