Toilet seat valve: which versions are most reliable?

All water tanks have such a complex component as a toilet flush valve. At the moment there are several varieties of this site. You should know everything about them before you buy the device or repair it.

Node assignment

The purpose of the device is as follows.

- It opens and releases water when the tank is empty..

- Prevents the flow of water after filling the tank to the desired degree..

- The locking element provides a constant level of fluid in the tank., if there are pressure drops in the water supply. When the pressure in the system drops or increases by 0.1 MPa, the water level should not change by more than 0.4 cm.

The general principle of operation that a toilet cistern valve has is.

- As the level of liquid in the tank decreases below the permissible value, the float sinks lower and lower and thereby activates the lever.

- The pressure on the pusher rod drops. As a result, water begins to flow into the tank.

- Simultaneously, the float begins to float upward.

- When a certain level is reached, the valve is closed with a lever, the water stops being collected.

A variety of designs of float elements depends on many types of drainage systems and tanks. For example, there is a check valve on the toilet and a direct counterpart. The principle of their work is very different.

Types of valves for tank

The closures of toilet bowls can be made of metal or plastic.

Manufacturing material

Expensive models of drainage mechanisms are made of bronze and brass. These metal alloys have good strength and rigidity, are almost not susceptible to corrosion, resistant to chemical and mechanical loads.

By design, they can be a simple separate units (bulk and drain valve), and complex prefabricated units.

Note! Lever-valve assemblies from alloys are made only for models of toilet bowls of the “elite” class. For the "business" category, metal shut-off and drain elements are made separate from the filler counterpart. This greatly simplifies the system, gives it versatility during installation and allows you to repair components separately.

Most often, the toilet cistern valve is made of plastic. From the quality of raw materials, as well as the accuracy of production of elements depends on the total price of the node. In other words, there is a direct relationship here - the more expensive the shut-off valve of the tank, the more durable it will be.

Device configuration

The locking accessories of the tank have only two configurations: you can install either a separate or combined system with your own hands.

- Separate inlet valve for toilet cistern and drain analog are mounted in turn.

- The interconnection of such elements is carried out only through water.

- The fill element is a simple knot of a certain shape, having a float.

- That by means of the control thrust, acts with an increase in the level of the liquid on the valve, she closes the water.

- A separate toilet cistern drain valve may have a push button, pedals, traction, etc.

- This element has a volumetric neck. With it mates air or mechanical valve. It comes off through the traction system or through a direct impact (lifting, pressing).

Note! The main advantage of separate drain units is the ability to replace or repair their individual elements. This circumstance greatly facilitates and reduces the cost of work.

- Combined mechanisms in which the filling and discharge elements are located in the same housing and are interconnected by a straight line, guarantee maximum safety and reliability of the tank operation.

- It is worth noting that such systems are difficult to repair, in addition, they are problematic to configure.

- However, the instruction notes that with fine adjustment such a node will work flawlessly.

Types of valves on a design

In total there are three constructive types of valves for tanks:

- croydon valves;

- membrane analogues;

- piston devices.

Croydon type devices

Such valves are technologically obsolete, they are found only on models of sanitary devices of the past.

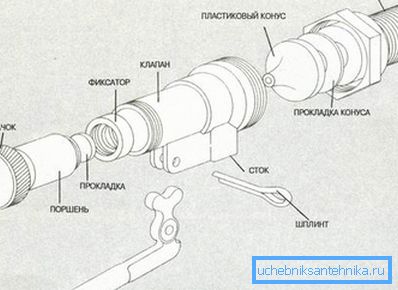

- They include a piston with a saddle, a lever axis and a valve body.

- Water is fed and cut off with a piston that moves vertically.

- It actuates its float lever.

This design quickly wears out. Therefore, over time, the valve in the toilet does not shut off the water, it flows and splashes out of the toilet tank.

Piston counterparts

- The inlet valve of the piston type toilet has an axis in the form of a lever.

- It is fixed in split pin (forked).

- When the lever moves horizontally, it causes the piston to move.

- That periodically touches the saddle. This regulates the flow of water into the storage tank.

- The piston has a seal on its end.

- When it mates with the saddle, the seal stops the flow of water.

Modern knots with a membrane

- Such a valve in the toilet bowl instead of a gasket is equipped with a membrane.

- Produce them from rubber or silicone.

- During the movement of the piston moves the membrane.

- Therefore, it, at the required moment, prevents the flow of water into the tank.

Similar valves are the most modern. They are equipped with all new models of sanitary appliances. Based on this, it is worthwhile to dwell on membrane devices in more detail.

They provide the most rapid filling of the tank with water and its overlapping. Based on the quality of the site and the accuracy of its adjustment, the process of recruiting liquid and its discharge can be silent or very loud.

Note! The main disadvantage of the membrane type of valves is that for their effective operation in the plumbing system there should not be significant pressure drops. Their value should not exceed 0.1 MPa.

In addition, for the mechanism to function normally and as long as possible, it is important that the water in the network be clean.

How a diaphragm valve works

The main phases of operation of the device are presented below.

First phase

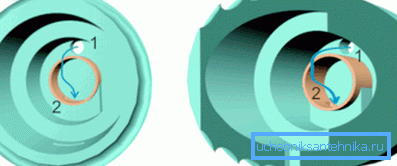

- In the first phase, the valve is open. During it, water enters the tank. The membrane, obeying the direction of flow of the liquid, moves away. Therefore, water without obstruction can fill the tank.

- At first, the liquid flows only into the preliminary section.

- So that she got directly into the tank, in this compartment there is a special hole. The process is similar to that which takes place in tanks equipped with rod valves, however there is a membrane stretched over the piston.

- There is a lumen in it, a plastic rod is passed through it. It also has a lumen section of 1 mm. Thanks to him, the water partially flows into the filling section.

- When the float is in the lowered state, a small hole is formed in the piston, having a diameter of only 0.5 millimeter. Through it a small amount of liquid flows into the tank.

- Due to the similar principle of operation of the diaphragm valve, the same pressure is created in the preliminary and filling sections and in the tank part behind them. This is the fundamental difference between such a mechanism and a counterpart having a rod valve.

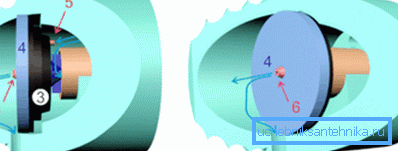

Second phase

- At this stage, the water enters the storage tank, with it simultaneously floats up the ball float.

- The process also increases the level of the stem with rubber seal.

- The seal clog the hole.

- Upon subsequent movement of the rod, the piston with the diaphragm is pressed against the saddle. Thereby, the filling section is sealed.

Based on the fact that the water pressure in the filling part of the tank is related to the pressure of the pop-up float, the membrane is very tightly pressed against the saddle. This prevents the flow of water into the storage tank.

Third stage

- The third stage is to drain the water after using the toilet bowl.

- At that moment, when the liquid comes down from the tank and flows into the bowl of the toilet bowl, the pressure effect of the float on the rod disappears.

- The slot in the piston at this time does not overlap the rod. On this basis, and in the filling section, the pressure decreases sharply.

- The pressure remains only from the water supply system, and it acts on the piston with the membrane, moving them to the side.

- Due to this, the drain mechanism again goes into the first stage.

Conclusion

The design of the drain system, including its valve, is of great importance for the efficiency and reliability of the toilet bowl. When choosing a sanitary device, do not forget to make sure that it is equipped with its modern model.

The video in this article contains a lot of additional information.