Wash 60 by 60 centimeters and others

Let's start with the fact that a kitchen sink of 60x60 cm or other sizes will not necessarily be made of stainless steel and with a patch type of installation - just this model that you see in the photo is the most popular among the population. Sinks of this type can differ significantly from each other and these signs can be called the materials from which one or another bowl is made, the method of its installation and the number of containers in one copy.

Below, we will discuss all these distinctive features in more detail, and for persuasiveness, we will show you the video in this article.

What is the difference kitchen sinks

By production material

- As already noted above, stainless steel is very often used for kitchen fronts, but it can be of different thickness, for example, a 600x600 mm stainless steel sink can be from a sheet whose thickness varies from 0.4 to 1.2 mm. As you understand, the thicker the steel, the harder the construction, therefore, it is easier to install, and there is no such danger of bending from shocks and other mechanical loads.

- Stainless steel, as a material, has very valuable qualities for this product. - she is not afraid of sudden changes in temperature, which is almost inevitable when washing dishes, as well as weak strokes that can be applied with a cup or a plate and such a bowl can be cleaned with almost all household (and not only) chemical means.

- Such a sink can be installed both in a laid-on and embedded way., but for this you may or may not need a tie-in. For example, if you have an ordinary cabinet under a sink 60 by 60 centimeters, then you simply put a bowl on its frame, but it could be a cupboard with a tabletop, where the container will have to be embedded.

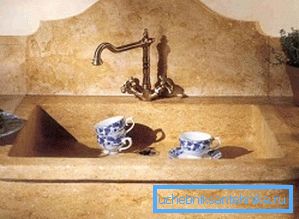

- Very presentable sinks made of artificial and natural stone, it may be granite or marble, but composite materials are still more popular and this has its own reasons. Firstly, the composite, unlike natural stone, is much easier to process (drill, cut), secondly, it weighs less and is easier to install, thirdly, the price of artificial material is lower, and, fourthly, the composite the texture is absolutely not inferior to this mineral.

- The composition of such composite materials includes about 80% of mineral (marble or granite) crumbs of small or medium fraction, and the remaining 20% of the volume is occupied by polymer resins with coloring substances (dioxides) and catalysts for hardening.. This mixture is poured into the mold and placed on the vibrating table for forced shrinkage of the components, then, after hardening, the mold is removed, and when the bowl finally solidifies, it is subjected to grinding on a polishing machine.

- It is noteworthy that an artificial stone of this type, like stainless steel, is not afraid of temperature changes, mechanical loads, abrasion and material fatigue. (wear or destruction of the structure over time).

- Very similar to the production of the above-described mineral composites, the manufacture of artificial onyx, however, the filler here is already seriously different in terms of quality and quantity.. Thus, artificial onyx contains about 65-67% aluminum dioxide and from about 2% to 7% color paste from mineral powder - all this is again mixed with polymer resins and catalysts for curing the composition.

- But the manufacturing process itself takes place in the same way - the mold is poured, the vibrating table is cast, the solidification and polishing on the polishing machine. Only here the hardness of such a composite due to the absence of mineral crumb below, therefore, a special film is pasted over the ground product, which gives it increased mechanical strength and protects against abrasion and scratches.

- Also for kitchens, single or double ceramic sinks can be used, but the concept of ceramics in this case includes either earthenware or porcelain.. Thus, faience has a lower density and is more porous material, but when making shells from it, they are covered with glaze, which makes both materials completely indistinguishable from each other during a cursory inspection.

- Ceramic products are very beautiful, they can have different colors and shades, be covered with patterns, but they are all afraid of a sharp mechanical impact (shocks, friction), and also sharp temperature drops are contraindicated to them, since they can break or crack.. In this regard, ceramic sinks are installed in the kitchen only in cases where the kitchen facade is equipped with a dishwasher.

Note. Any sink 600 by 600 by 800 centimeters or single, is selected in accordance with the interior of the kitchen room. And if stainless steel is appropriate in almost any case, then composites and ceramics should strictly comply with the design.

By installation method

So, the most common for kitchens wasted stainless steel washbasin 60x60 cm, maybe also from another material - artificial marble, granite, onyx and ceramics - this is not about him, but about the method of installation. Under the overhead installation of washing means the way when the bowl is fixed on the cabinet or cabinet with its horizontal sloping sides, that is, the container simply hangs on the furniture.

In most cases, the seat is already ready to be installed, for example, a 60x60 cm sink stand for a kitchen does not have a tabletop at all - there is only a frame - the front, rear and side walls, on which the sink is lowered. But sometimes a seat for the tank is not provided and it has to be cut in the tabletop by yourself.

To cut a hole in a package with a sink, there may be a sheet of cardboard on which the perimeter of the sink hole is drawn - all you have to do is cut out the cardboard with scissors and transfer the dimensions to the table top. But such a stencil may not be, then the container is turned upside down, depicts its perimeter, and then another line is drawn from the inside, departing from the initial mark to the width of the rim.

For cutting in such cases, an electric jigsaw is used - all the irregularities that are possible when cutting chipboard with such a tool are overlapped by the sides of the shell.

Note. When cutting the seat, the heel of the jigsaw will leave black stripes on the tabletop surface. To avoid such consequences, coat the outside of the perimeter with masking tape.

The built-in sinks look more impressive - this means that the bowl is either flush with the table top and holds on to additional fasteners, or its sides are located slightly below the surface and fixed with the help of two-component or polymer glue. That is, in this case, the capacity is not held due to the emphasis of the sides on the frame of the furniture.

If you get a built-in sink made of artificial stone and furniture with a homogeneous tabletop, then there, most likely, there is already a seat and you just have to put the container on the glue that comes in the kit. The joints after gluing are practically invisible, but to the same, you will need to wipe the strip of glue that has protruded to the outside.

Of course, there are cases when you need to cut the stone countertop with your own hands, but here it is better to invite specialists with the necessary tool.

If you embed the sink in the countertop of the chipboard, then you can take care of cutting the seat, but for this you will need a router with nozzles and, of course, some practical experience with this tool.

Most often, these sinks have a hard pattern that is attached to the countertop with clamps and through which a hole is cut, then a sharp edge is removed. After that, the table top is turned upside down and according to the configuration of the sink, the grooves are sampled by a router, where the sink is subsequently glued.

Conclusion

For complex installation (mortise embedded models) in the plumbing kit almost always have installation instructions from the manufacturer, which should always be used if you are working independently. However, you can purchase any of the types of sinks for your kitchen façade, and to install, invite an outside specialist who has the experience and the right tool.