What could be a monolithic shower tray

When a major overhaul is started in the house, many people start to worry about how to choose a shower tray, because there are a lot of options in shape, size and materials, and in all this variety it is quite easy to get lost.

But in order to dwell on something, you need to understand what the construction market generally offers in the plumbing section and what you can do yourself, as well as how it is mounted and what its positive and negative sides are.

Let's try to understand this information together, and also watch the video in this article.

Shower trays

Note. It should be noted that pallets of any shape and size and made of different materials, most often designed for fences of tempered glass or plastic, which are mounted on it using a frame made of metal profile.

Materials

- Plastic shower trays are the most common on demand and demand, and to be more precise, they are made of acrylic (a colloquial term) or polymers based on acrylic acid. Such containers can have different depths (shallow, medium, deep) and different shapes, which makes them almost ideal for the equipment of a shower stall, because they have little weight for all other advantages, are easy to install and their cost is quite democratic for the average Russian.

- Of course, such a pallet cannot be called monolithic, but we decided to mention it, because Russia can be without wood products and this also applies to shower cubicles.. For the manufacture of such containers, oak and larch are used and it is quite natural that it weighs 3-4 times more than the same plastic shower tray, but wood always has bactericidal properties. Wooden products often do deep, ranging from 15 cm and more.

- The so-called iron shower tray can be made of thin sheet (1.5 mm) or thick (from 3.5 mm and above) steel, or of cast iron. Both designs are metal products, and they are quite cold, therefore, before taking a shower, they should be doused with hot water. Its strength and durability can be attributed to the positive qualities of the metal, but any paint, which invariably covers such products, is their weak link, since it cracks and darkens over time, although it is quite possible to repaint the tray if a specialist does it. Regarding the depth of the tank, there is not much to say, as it usually does not happen more than 10-12 cm, which corresponds to the average category.

- The faience shower tray has a rather attractive appearance, but its installation requires a perfectly flat surface, since with the slightest bias of the floor, the vertical capacity load will lead to its destruction - the tray will simply break. You can, of course, buy ceramics with a stronger structure, this is porcelain, but the price of such a product will turn out to be almost twice as high as the earthenware, but you need to pay good money for good things. In depth, such models are often made shallow, with sides up to 5 cm, and sometimes even in the form of a small depression in the direction of the drain and the sides there are not there at all.

- Nowadays, composite materials have been used more and more widely, for example, such shower trays made of artificial stone, as you see in the top photo, can imitate not only marble, but also granite and onyx, and, thanks to dyes, such products can give almost any color and shades. The composite even surpasses natural stone in its strength, since synthetics make it more resilient and it does not crack when struck, but it is easy to process and has a much smaller mass, which makes it most convenient for installation work. Products made of composite materials have practically no restrictions on the operational resource with proper care - you can spoil such a container only by active mechanical action, and this is either on purpose or when the building is destroyed.

Homemade pallets

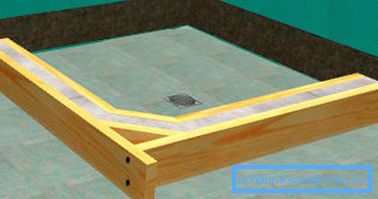

Note. You can always make a cast container of this type with your own hands, for this you need formwork and fine-grained concrete in proportion (cement M400 / sand / sifting) 1 / 1.9 / 3.7. With this ratio, you get the brand M300 or class B22.

First of all, you need to determine the height of the floor near the pallet and, according to this parameter, install a drain, so that the slope of the sewer pipe is about 2-2.5 cm per linear meter, as required by the instructions. Then collect the formwork for the sides, so that the wall thickness when casting is not less than 10 cm, and you already choose the height yourself.

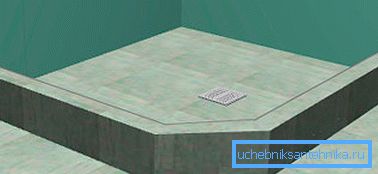

It is possible to remove the formwork in 2-3 days, but this does not mean that the structure is ready for operation - this has only completed the process of setting the mortar and the process of solidification has begun, and the full cycle of solidification lasts 28 days - four weeks.

After the final hardening of the concrete, you will only have to overlay the sides and floor with ceramic tiles, as shown in the top photo, and in a week it will be possible to start its full operation.

Conclusion

I would like to note that acrylic or, as it is called, plastic shower tray is not only the most popular, but also the most convenient among all the above analogues. It has three main qualities that people pay most attention to when buying - it is easy installation, ease of use and low cost (see also the article Deep shower trays: what is their advantage).