Why do we need a sealer for showers, and what types it is

Shower cabins, as you know, are prefabricated structures consisting of a large number of parts. To ensure the tightness of all the joints of these elements using seals. Below we take a closer look at which nodes of the booths they are used in, what types are there, and also get acquainted with the process of their installation.

General information

The main task of seals, which are popularly called rubber bands, is to prevent moisture from entering the shower cabin to the outside. Therefore, they must be installed around the perimeter of the glass and plastic walls, as well as doors.

The main requirement for seals for shower cubicles is elasticity.

In addition, they must comply with the following qualities:

- Moisture resistance;

- Resistance to temperature changes;

- Durability.

However, even in this case, the elastic bands fail much earlier than other elements of the structure, therefore, they need to be replaced from time to time. This is especially true of low-cost models of cabs, in which accessories of not the highest quality are used.

Kinds

Materials

Most often considered products are made from the following materials:

- Silicone - this type of rubber is the most common because of the high elasticity and wear resistance of products, as well as compatibility with silicone sealant. Due to the large range of silicone seals can be used at the junction of a variety of parts of the booth.

- Thermoplastic elastomer - this material belongs to rubber polymeric structures. Its peculiarity is that at room temperature it has the property of rubber, and when heated it takes on the quality of a thermoplastic. After deformation, the product returns to its original shape. In terms of performance, thermoplastic elastomer is more attractive than rubber; however, its price is higher.

- Rubber - operational qualities of rubber seals are inferior to products from other materials. However, their positive point is the low cost, as well as good mechanical strength. As for the service life, it is lower than that of products from silicone and thermoplastic elastomer.

Tip! Silicone sealing for a shower cabin can be used for glazing balconies in a frameless manner and mounting other glass constructions.

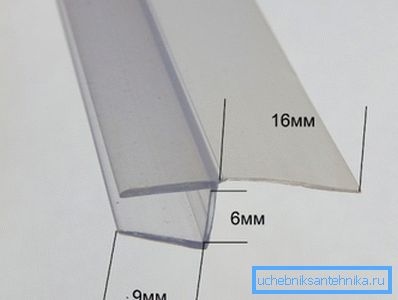

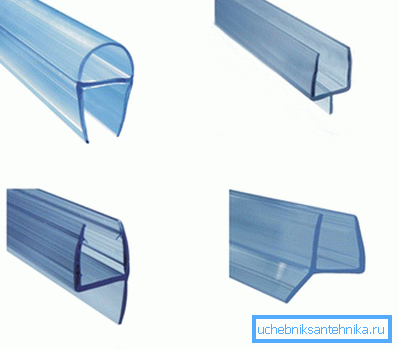

Seal Profiles

Depending on the profile, silicone seals are of the following types:

| Seal type | Application |

| A-shaped | Apply at the joints of glass with glass and glass with a wall. |

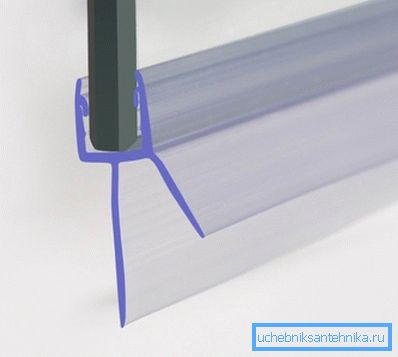

| T-shaped | This sealing rubber for a shower cabin is installed below on the doors, at the same time the side prevents the penetration of splashes from the cabin to the outside. |

| H-shaped | It can be installed in the joints of doors. |

| Drip pan | They differ in that they have two petals:

|

| Universal | Can be mounted between any elements of the booth:

|

In addition, there are highly specialized gum. These include the rubber seal on the shower tray, which is mounted between the bowl and the wall, as well as some other sealing elements.

Magnetic

Separately, it should be said about the magnetic seals. In fact, this is the same silicone gum, which is installed on the edge of the door. Its feature is the presence of a magnetic rod, which provides tight closing of the doors and their fixation.

It should be noted that each magnetic seal for a shower cabin is designed to close the valves at a certain angle.

It can be:

- 180 degrees;

- 135 degrees;

- 90 degrees.

Tip! If none of these options are suitable, you can purchase a seal-latch, the angle of which is adjustable with your own hands.

Installation Features

The process of mounting the gum is not a big deal, however, there is a certain instruction that must be followed in order to make all the connections tight.

All work is done as follows:

- First you need to clean and degrease all surfaces that will be in contact with the rubber bands. For the convenience of this operation, it may be necessary to dismantle some panels. To do this job correctly, it is advisable to familiarize yourself with the design assembly scheme.

- Then the mating surfaces must be protected with masking tape so as not to stain them during work.

- Next, work surfaces need to be treated with a thin layer of silicone and put gum on them. Excess sealer should be removed immediately, until the composition is frozen. All joints should be tightly pressed.

It is possible to operate the cabin several hours after the installation of all elements, when the sealant hardens. In order to check the quality of the seal, a water jet can be directed to the places where the sealing elements are located.

This sealing process is complete. Despite the fact that the work described is quite simple, it must be done carefully and efficiently.

Conclusion

Seals are an important element of shower cubicles, as they are responsible for its tightness. And from time to time they need to be replaced. However, as we found out, it is possible to pick up suitable elastic bands and install them without the help of specialists.

From the video in this article can be found with some additional information on this topic.