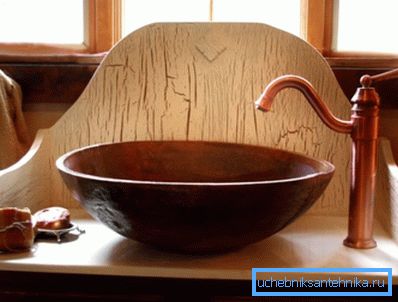

Wooden sink for washbasin and bathroom

It is not difficult to meet a wooden bath in the sauna, this place is filled with a combination of health and nature around us. Another thing is a washbasin sink, which is a rare guest not only in such establishments, but also in apartments. This is mainly due to the high cost of this plumbing. Today we will tell how to make a wooden sink with his own hands, as well as a bath, while saving a significant amount.

Wood is a natural product with an excellent insulating effect. Therefore, in such a bath the water will stay warm much longer.

They produce sinks in modern design, and the material can be combined with anything. Custom-made bathtubs and washbasins can be very expensive.

The use of wooden shells in wooden houses will only accentuate the taste of their owners. The material is environmentally friendly, waterproof, has an interesting design. If used in the manufacture of glued bamboo array, the sink can take on any shape.

In the interior

While to meet the wooden sinks in the interiors rarity. It may seem that they are generally not compatible with plumbing, but this is not the case, for which there are enough examples.

When there was no earthenware and porcelain, almost everything was done from wood, not to mention the soups, barrels and troughs. Then it was possible to surprise the guests of the bathroom from cast iron, but not from wood.

The material familiar to our great-great-great-grandfathers today is a wonder for many. At the same time, lovers of natural and eco-friendly interiors believe that this is a mandatory attribute of a stylish and expensive room design.

We have long been accustomed to the furniture of valuable wood, floors, so if you want to really surprise your friends and hit them to the depths of the soul, make or buy a sink made of wood.

| Beauty and form | The decoration of plumbing will have its luxurious and unique texture. Thanks to the skill, it can be turned into any form:

|

| Breed | It is advisable to use moisture-resistant and hard wood for manufacturing. These include:

|

| Treatment |

|

Tip: although the washing of wood and unpretentious in the care, avoid the use of cleaning products with abrasive particles in its composition.

Washbasin sinks without bottom

Manufacturers often surprise us with their models, sometimes entering into a stupor. For example, the company "Lago" proposed a version of a wooden shell, in which "there is no bottom." Of course, this is only an optical illusion and it is present, but you must agree that such an unconventional approach can lead both to delight and bewilderment.

If we study the design and execution of the model, we can say that it will be possible to reproduce it with our own hands. For this you will need a tabletop 80-90 mm thick, made of spliced wooden timber. It will need to make a rectangular hole, which will serve as a sink.

Tip: do not forget that the wood from the constant exposure to water must be protected with special compounds.

For this construction, keep the wood structure intact and cover the surface of the tabletop with several layers of lacquer. You did not forget that the most interesting in this model is hidden at the bottom?

For him, prepare a clear glass, placing under which, for example, 3D images. So you can get interesting visual effects.

If you do not use anything, then you get the illusion of the illusion of lack of a bottom. Which will also be interesting.

To obtain all the listed effects, a specially designed water drainage allows. It does not go away from the bottom, as in ordinary shells, but passes through a slot placed on the back wall of the bottom, and then flows through the chute into the siphon.

Thanks to this, we managed:

- make a solid bottom cover;

- surprise acquaintances and friends of the "lack of bottom" at the sink, if you hide the siphon and use clear glass.

Sink in solid wood

This option shows how to make a wood sink with your own hands in an array of glued bars.

Below is a process instruction:

- It is necessary to glue the bars together. Thickness depends only on your wishes.

- Mark them on them.

- Take a circular saw and cut it to the desired depth.

- Take a chisel and a hammer and remove the excess.

- Sand the resulting container.

- Making a hole for draining.

- Take the epoxy glue and mix the resulting shell.

Wooden bath

Now let's talk about a larger sink - a bathroom. Its price in retail chains is off scale, so why not make it yourself if you have time and desire?

The process cannot be called simple, but it can still be done.

Tip: choose a rectangular configuration, it is easier to manufacture and easier to seal.

- Prepare also need special woodworking tools.

- The principle of operation is one thing - you need to make a sealed wooden box. What is needed is a qualitative fit of the wooden elements of the structure to each other. You should not hope that the wood from the water swells and closes all the cracks.

- The important moment of making a wooden bath is the polished surface at the end of the stripping stage. Otherwise, it will not be safe to take water procedures in it.

Tip: outside the bath must be protected in any way, but inside it is allowed only polishing, varnishing is not applied.

Conclusion

Natural materials always decorate any interior, especially when products from them are made independently. Above, you learned how a wooden sink for washbasins is made, as well as a wooden bathtub (see also the article Sink in marble: natural stone and an artificial counterpart).

Even if you do not have certain skills, your desire will be enough to get a positive result. The video in this article will provide an opportunity to find additional information on the above topic.