Disinfection of ventilation: the need and the cleaning

Ventilation systems have been used by mankind since ancient times to maintain a certain microclimate in the room. It should be noted that during operation they are constantly clogged and this can cause a lot of very serious problems. That is why the question of how to clean and disinfect ventilation is very interested in many masters.

Necessity or myth

First, it must be said that the problems of clogging pipes of such systems are not a bloated myth of cleaning companies. This is a very serious problem that, if it is not given due attention, it can lead to property damage and even death.

Pollution effects

- Most often, such systems are clogged with household dust, grease and other substances that are peculiar products of human activity.. At the same time, they all easily ignite and can become a source of ignition. That is why the fire safety manual strongly recommends periodic cleaning.

- It is worth noting that very often the fire from one room is transferred to another precisely through ventilation.. Especially if during a fire the system is turned on and air circulates in it.

- In addition to dust in the ventilation ducts, various infectious diseases are often born. This is due to the fact that they form an environment that is excellent for the maturation of the fungus or mold, which, in turn, are the source of pathogenic bacteria and even toxins.

- The least terrible effect of contamination of such a system is that an unpleasant smell constantly emanates from it.. It can cause discomfort and cause allergies.

- The fact that a polluted system works less efficiently deserves special attention.. In this case, the electrical equipment in it is often at risk of failure. Very often, blockages cause damage to the impeller or fan wedge.

Tip! Lattices of such structures should be cleaned periodically. If they are in the premises where cooking takes place, then this should be done daily.

Self cleaning

It should be said that the disinfection and cleaning of ventilation have their own frequency and are quite complex. Given this, many people believe that it is enough to perform mechanical processing on their own and for this purpose install inspection hatches.

However, unprofessional service cannot produce the same effect that is achieved by the work of specialists, especially if we take into account the fact that after each such prophylaxis more and more garbage accumulates in the same places.

On this basis, it makes sense to make independent maintenance only in conjunction with periodic professional prevention. The fact is that specialists do not just wipe the internal cavity of the system, but at the end of this process produce special treatment with antibacterial drugs.

Tip! If you do not have experience of similar work and appropriate personal protective equipment, then you should not start this operation yourself. This can lead to infection and will not give proper results.

Phased cleaning process

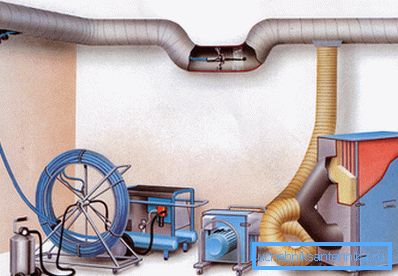

Proceeding with this process is necessary only if there is special equipment for the disinfection of ventilation and protective equipment. In this case, you may need inspection hatches that are already mounted on top of the finished system.

Training

- First of all, you need to turn off all electrical equipment that runs on the highway. Many experts recommend doing this physically by unplugging the power wires.

- Next, the entire path of the air masses is checked through the ducts and, if necessary, additional plugs and inspection hatches are installed in the system. They are necessary to connect the appropriate equipment and sealing of individual sections. It is worth noting that the disinfection and cleaning of ventilation is carried out in separate segments, which means that they need to be prepared, separated from each other.

- Also at this stage, filter grids are removed, which mechanically prevent debris from spreading. Usually they are not cleaned, but simply replaced with new ones. However, to save money, some experts simply expose the old filters to steam treatment, and then apply an antibacterial solution to them.

Tip! If during installation of technical hatches damaged ventilation segments were detected, then it is necessary to immediately replace it. Soldering or other work to eliminate the defect in this case is simply not appropriate.

Cleaning

Next, you need to make the connection equipment. If the work is done by hand, you need to clearly remember that a pump with hot water supply or a device with mechanical cleaning is attached to the input end, and a vacuum pump is attached to the other end of the section.

After both devices are turned on, the removal of grease and dust from the walls of the ventilation duct will begin. At the same time, the removal of slags and dirt, which fall on a special replacement filter apparatus. Its price is relatively low, which means it’s not worth saving or using it twice, because in some cases they are subjected to laboratory analysis.

Tip! There are special temporary standards that determine the duration of such activities with the complete absence of people living or working in the room. They should not be reduced, as this will either result in poor cleaning or harm people's health.

Disinfection

After the mechanical cleaning and rinsing has been completed, it is the turn of disinfection. Usually special sprays or aerosols are used to perform this process. They are filled with an antibacterial composition, which disappears very quickly.

It must be said that there are many different products for disinfection, which prevent the subsequent appearance of fungus or mold. However, it is necessary to use those of them that, in addition to their effectiveness, would be harmless to people.

Such substances include mixtures of the type:

- “Samarovka”,

- “Relight”,

- "BioPag-D" or the like.

It is very important to say that in the process of spraying antibacterial substances in the system, washings from the surface are collected. They are necessarily transferred for analysis to an independent laboratory, which gives its conclusion, which is an indicator of the quality of the work performed and the reason to draw up a final conclusion.

This is especially important if the structure is operated in the food industry or in administrative institutions.

It should also be noted that in certain types of premises disinfection is carried out according to a special program, which includes a whole range of works. This includes insect harassment and deratization.

When the work is completed, the whole system is again merged into a single whole and begin to carry out ventilation in the most accessible mode. This prevents the presence of people in the room, as there is evaporation of the treatment solution may be present in the main line.

Conclusion

After studying the video in this article, you can get more information about this process and its features. While taking into account the article proposed above, it is necessary to conclude that such work is best trusted by professionals who have the appropriate equipment and experience.