Examination of ventilation for timely detection of problems

The quality of work of any communication systems depends on timely testing for the level of clogging and serviceability of the main elements. As for the systems with air channels, regular control plays an important role here too. There are several reasons that encourage inspection of ventilation.

Detectable defects

Determining the defects in advance is very important, because the system is constantly exposed to aggressive effects. On the walls are usually accumulated fatty deposits, dust, biological waste and other contaminants, which directly affects the quality of air circulation.

The following is what a survey of smoke and ventilation ducts can provide.

- Determination of damaged areas allows you to make repairs in a timely manner, until the internal environment began to penetrate out.

- The determination of the level of contamination makes it possible to carry out cleaning before the violation of operational characteristics.

- During the inspection, it is possible to select the means and technologies for cleaning the system.

- Detection of problems with the equipment is also possible to identify by doing a survey of the ventilation ducts.

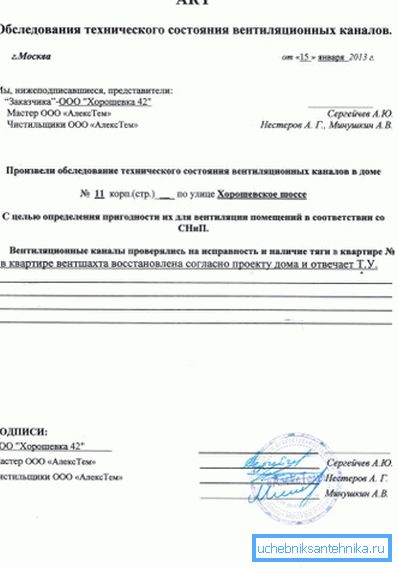

Addition! Timely inspection of airways provides an opportunity to assess the effectiveness of cleaning the system and compile all necessary documentation for supervisors.

Stages of work

All problems with a particular system can be identified by passing through several stages. All of them are listed below in order of turn, so that you can get a clear picture of working control. At the final stage, it remains to look at the inspection report of the ventilation ducts (see also the article “Greenhouse ventilation - types and characteristics).

Operations with working and project papers

The first is a preliminary study of documents for compliance with technical conditions, regulations and the main design assignment. Next is checking the optimality of the selection of equipment and the feasibility of the location of the systems. The monitoring of calculations related to the moisture content, thermoregulation of the air and calculations of the air flow are performed without fail.

At the finish of the first stage a special conclusion is issued confirming the above data. If necessary, experts give advice on the addition and modification of the project provisions.

Quality assessment of the work performed

- Examination of the ventilation systems for compliance with the basic design of all the work carried out.

- A check is made of assembly measures in order to verify the data obtained with the standards.

- The quality of adjustment and network settings is checked, because the actual air flow must match the project.

Note! When the assembly work is monitored, the welded and flanged joints are checked, the build quality of the elements and equipment is determined, the price of which is quite high.

Determining the causes of malfunction

The actual measurements of the main indicators of the air environment are necessarily made, that is, the temperature, pressure, humidity, and the flow rate are calculated. The results obtained are compared with the calculations made at the design stage.

The parameters of the air flow inside the channels are determined and correlated with the initial data. At the same stage, checking the level of network clogging. During the work using the usual endoscope.

The obtained figures should in any case comply with the provisions of SNiP 41-01-2003, which reflect the general requirements for ventilation systems and other communications. In the issued certificate there are usually recommendations for restoring the normal operation of the network.

Applicable Tools

To carry out the control, at least a minimum set of technological equipment is required. Used measuring devices must be checked every year for compliance with the established requirements. The table provides a set of the most necessary devices.

| Type of fixture | Main purpose | Verification |

| Anemometer | It is used to measure the speed of air masses. | + |

| Aneroid barometer | Allows you to determine the relative pressure. | + |

| Thermohygrometer | Measures temperature and relative humidity. | + |

| Range finder | Required for measuring channels and rooms. | + |

| Backlit video camera | Used for visual inspection. | - |

Explanation! Video control is a very effective tool, as it allows you to find collapses and debris. Especially it is very convenient if trials are coming.

About microbiological test

Special attention should be paid to the study of the walls of the system for the presence of biological mass. In the process of testing, washings are taken from surfaces located inside pipelines. Two weeks after taking a sample, you can make a decision on disinfecting the network with special chemicals.

The main result of testing can be only the conclusion of a certified laboratory. After the implementation of disinfection measures are diagnosed and re-examination. With the right approach to the process of biological waste disposal, just one treatment is enough.

As a conclusion

A survey of the channels of the ventilation system should be carried out first of all with noticeable decrease in efficiency, especially if the entire network was mounted directly with your own hands. These instructions allow you to get a detailed understanding of the principles of the work, so that each individual developer knows the importance of this procedure (see also the article Ventilation from galvanized steel is a universal solution).

The video in this article is a visual aid for studying the topic.