Farm ventilation - need, types and additional working

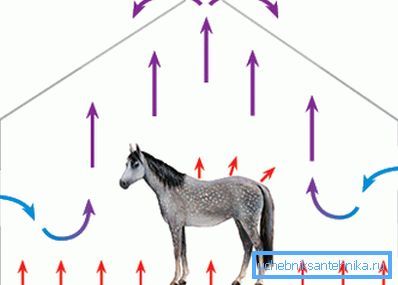

If you are engaged in raising animals, the premises for their maintenance must have good ventilation. Proper air exchange creates the necessary temperature and humidity for development, which have a beneficial effect on the livestock, reducing feed costs and increasing its productivity. Due to the ventilation of the rooms, ammonia vapors are removed from them, and the environment for the development of pathogenic bacteria is not created.

When designing a ventilation system for cattle-breeding complexes, it is necessary to ensure that there is no excessively intense air flow that can lead to drafts. This often leads to diseases of the population and a decrease in its productivity. In winter, it is necessary to choose the optimal mode of heating the air so that the economy does not spend a lot of money on it.

The need for ventilation of livestock buildings

The physiological activity in the organism of animals is greatly influenced by external conditions, among which the air environment occupies one of the main roles.

It affects the body due to the combination of the following indicators:

- temperatures;

- relative humidity;

- the speed of movement of air masses;

- radiation;

- radiant energy;

- mechanical particles;

- chemical impurities;

- microorganisms.

In the same way, an indoor climate is created in the room, which is called a microclimate.

Its development is determined by a number of technological and technical solutions related to:

- layout;

- construction;

- heat protection;

- the quality of external enclosing structures;

- technology content and nutrition;

- animal accommodation;

- air exchange, heating and sewage systems.

Because of this, the process of managing it is difficult. However, the organization of a standard microclimate indoors is one of the factors for the normal development of physiological processes.

Tip: ventilation rates in poultry houses are calculated by the formula - K = L / V, where K is the air exchange rate, L is the air volume per hour, V is the ventilation volume in m3.

Ventilation work depending on the season

Supply air volume (1 m3/ h per 1 kg of animal mass) is associated with the time of year. For example, in the warm period, the instruction allows an increase in the air temperature in the room above the calculated one up to 5 ° C, and its speed of movement up to 1 m / s. If this is not enough, you should use air conditioning or other methods of lowering temperature indicators.

Tip: when selecting a ventilation system, eliminate internal and external recirculation of polluted air, as a result of which intense dust, microbial and chemical contamination of air is possible in the room.

In this case, it is necessary to provide for the supply of clean air due to the centralized inflow system or to capture intake air masses at some distance from the point of discharge of the spent air flows. It is necessary to remove the dirty air from the room through the ventilation pipes to a height that excludes strong air pollution over the territory of the livestock breeding complex.

Tip: it is forbidden to combine or closely place the supply and exhaust ventilation channels.

Air supply and exhaust units

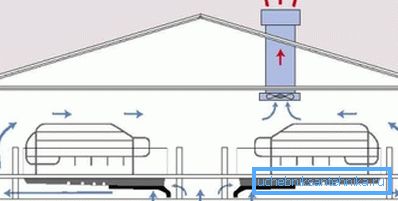

Used ventilation systems in livestock farms operate on the principle of air exchange. They have a different working principle and design features. There are vents with natural, artificially induced traction and mixed.

Natural

With natural ventilation, air masses are fed and removed from the premises by specially arranged ventilation channels due to the pressure difference inside and outside the structures. It can be pipeless (horizontal) and pipe.

Most often used last, consisting of pipes for exhaust and intake ducts.

| Section of exhaust pipes | Normal operation of the inflow and exhaust air masses depends on the correct device and the cross-sectional area of pipes and channels. Today, the section of exhaust pipes for this type of ventilation is as follows:

|

| Air flow | A prerequisite for normal operation of the hood is the organization of a sufficient flow of outside air. These channels should be located at a height of approximately 2 m in the longitudinal walls. Outside, their openings should be protected by wind shields, and the internal ones should have baffles that can regulate the amount of incoming air and its direction. |

| Pros and cons in work | Positive characteristics of natural supply and exhaust systems:

The disadvantages are associated with a small temperature difference in the warm season, which is why the system does not work normally or it can completely stop working. This is the reason for its narrow application. |

Tip: the rate of air exchange per hour in livestock farms should be 4-6 times.

Artificial

In this case, the inflow or extraction of air flows occurs under the influence of their discharge or discharge by special fans. The design and schematic diagram of the ventilation unit is determined based on the type of structure, technology of keeping and placing animals in it. Estimated power depends on the required air exchange and fan performance.

Today in livestock buildings use:

- installations for air exchange with mechanical exhaust, when fans for removal of exhaust air are placed in exhaust shafts;

- ventilation units with artificial inflow stimulation;

- systems with forced influx and exhaust.

Tip: the operation of natural and forced ventilation, conducting air exchange in a room without prior preparation of air only on the basis of biological heat, is allowed in winter to an outdoor temperature of -14 ° C.

Otherwise, the air temperature will begin to drop in the building.

Air flow heating

- For this purpose, ventilation systems with forced induction of inflow are often combined with water and steam heaters, as well as with electric ones.

- Have a heating and ventilation unit in a special chamber or directly in the room in the form of a monoblock.

- Saving heat energy is due to various heat recovery installations in the ventilation system, while the heat of the exhaust air is used to heat the incoming air.

- For this purpose, systems such as regenerative, regenerative, and others are used.

Tip: Use heated air curtains to prevent cold air from entering the room through the open door from the outside.

Noise reduction

The work of mechanical fans is often accompanied by noise of different strengths associated with the installation of equipment. If everything was mounted correctly, its intensity will be equal to 57-80 dB, in case of an unregulated system with unsatisfactory installed shock absorbers, the parameter can reach 100-120 dB.

We recommend testing the ventilation before final commissioning, paying attention to the installation of shock absorbers, as well as the connection of the fans to the air ducts using tarpaulin inserts.

Conclusion

The maintenance of animals and birds in enclosures requires the creation of a favorable air environment for them, which will make it possible to increase the productivity of livestock and reduce the cost of feed. For this purpose, natural, forced and combined ventilation of the premises is used, depending on their dimensions.

This article has been told about the general parameters of creating an animal-friendly environment.

The video in this article will help you find additional information on this topic.