Find out how to properly install the ventilation grille

Ventilation is one of the most important engineering systems necessary to ensure a comfortable climate in any type of premises. In domestic ventilation systems, the most common equipment for air ducts and ventilation shafts are grilles. They are installed in the vent channel channel directly at the entrance of the air flow into it, which has already washed the room.

Installation methods for ventilation grills

This section describes the simple installation instructions for a simple construction of the grid, which can be performed in several ways:

- Fastening with screws “flush” is perhaps the easiest and most affordable method of self-installation of vent grids. It is applicable to almost any surface of walls (concrete, wood, brick, plasterboard).

It is executed as follows:

- Mark up the place of mounting on the wall.

- In the case of concrete and brick walls, it will be necessary to drill holes for dowels with a drill or a perforator.

- The mounting holes on the grill itself are machined so that the head of the screwed-in screw lies flush with the surface of the frame.

- Next, apply the product and tighten the screws.

Note! Whatever way you do not use, the main thing in the process is a very tight attachment to the wall without cracks and gaps. In some cases, you can even use silicone sealant to insulate the duct.

- By means of a plinth or shtapik ventilating wooden lattices fasten. Other types of products are also attached, but indoors with wooden veneer or decorated with wooden objects.

- Fastening on glue of fast action like "liquid nails" (Dragon, Titan), silicone, etc.

With this method, you should act as follows:

- Squeeze the glue strip using a special device-gun along the contour of the ventilation barrier.

- Press the grille tightly against the wall.

- Fix it in this position will help mounting foam.

- The next day, the foam is removed.

- Another common and simple way is to mount on spacers.

Tip! In places where it is not convenient and possible hermetic installation of the grille in the ventilation system using an adapter for the ventilation grille.

For indoor installation, give preference to environmentally friendly, non-toxic products.

Types and purpose of ventilation grilles

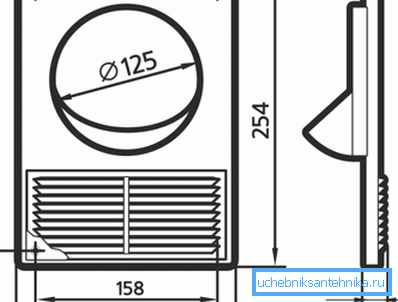

Grilles for ventilation systems are represented on the modern construction market in a wide variety of shapes, sizes, designs and materials of manufacture. Depending on the above parameters, the price of a product also changes. In the following sections we will tell you about the features of these products.

Installation location

Experts distinguish between ventilation grates on the main grounds. The main place in the classification of the products we are considering takes place and the method of their installation. By this feature, vent grilles are divided into:

- Internal - usually beautiful ventilation grilles are installed from inside the premises. Their designs are not subject to special loads, so they are made mainly of plastic.

Such products are characterized by:

- Small sizes.

- Visual appeal.

- A variety of styles and colors.

All this allows anyone, even the most demanding customer, to choose the most suitable model, organically combined with the overall interior design of the room.

In addition, the internal subclass is very simple and easy to install by hand and further exploitation. Often, the internal ventilation grille with a valve that allows you to easily adjust the direction and intensity of air in the room.

- Outdoor. According to the name, these products are mounted on the outside of the building. The purpose of the outdoor grilles is to protect air ducts from penetration of dust, dirt, insects, rodents and precipitation. These are, as a rule, ventilation louvered grilles made of high-strength aluminum, resistant to the effects of aggressive manifestations of the external environment.

- Downstream. Ventilation overflow grilles are used for air exchange between rooms. Products of this type are equipped with V-shaped blinds arranged in such a way that they overlap each other. This provides light and sound insulation between rooms. There are special ventilation grilles for doors, partitions and walls, etc.

Note! For underground ventilation channels use special ventilation floor grilles, made mainly of aluminum or wood.

Design

The next sign that determines the classification of lattices is their design features.

According to them, distinguish such designs:

- Adjustable products are equipped with movable louvers, opening and closing of which significantly affects the speed of air movement and the intensity of air exchange.

- Unregulated. The name speaks for itself. These are simple constructions without additional functions.

- Inertia grilles are able to automatically close the blinds in the absence of air movement.

Materials for production

Ventilation grilles are made from various materials.

Based on this product are classified into:

- Plastic.

They are distinguished by:

- Low cost.

- Resistance to biological effects.

- Convenience and ease of care.

- Possible change in color and shape under the influence of ultraviolet.

- Aluminum products are lightweight, durable, not afraid of direct sunlight, but more expensive than plastic.

- Wooden lattices are used exclusively indoors. These eco-friendly, aesthetic products harmoniously fit into the most sophisticated interiors. Lattices are made of solid wood, so they require special care and cost a lot.

- Steel ventilation grilles are very strong and durable. They are much heavier than aluminum structures and are much more expensive.

Interesting! In the production of kitchen and dining room sets, furniture ventilating grates are often used; these are traditionally woodwork or rattan.

Product Form

The fourth of the main features that determine the classification of vent grids is their shape.

In this case, the options are much larger than the basic geometric shapes:

- Square.

- A circle.

- Oval.

- Rectangle.

Manufacturers of ventilation grilles, especially for indoor use, do not stop in finding new forms and décor of their products.

Of course, for the design of ventilation channels from the street, simple ventilation grilles are used, round or square or rectangular. Of course, if we are not talking about special architectural solutions of the building, when every little thing should correspond to a common ensemble.

Attention! When purchasing a grill, remember that it is inherently an obstacle to the flow of air going to the ventilation duct. Choose a design that does not reduce the performance and efficiency of the ventilation system as a whole.

Conclusion

After reading the above information, you probably found the answers to the questions posed and now have an idea of what the ventilation grill is and how it is attached to the wall. Remember that airing the room is necessary not only for aesthetic reasons (to remove odors), but also good for health (air is discharged).

In the presented video in this article you will find additional information on this topic.