Flexible air ducts for ventilation: features of the device

In this article we will talk about what are flexible air ducts for ventilation, how and from what they are made and what are the features of their use. The topic of the article is of considerable interest, since, in addition to operation in industrial systems, flexible ventilation ducts are used when installing household extracts in kitchens.

Despite the fact that a wide range of rigid round and rectangular channels is on sale, the need to use flexible pipes does not become less relevant. The reason for the popularity is that the hard channel on some uncomfortable parts of the surface can not be installed.

Again, on some surfaces with a large number of protruding sections, putting a rigid structure with a large number of joints is simply unprofitable. The use of multiple taps can replace the purchase of a flexible pipe, which is characterized by a high degree of tightness and operational reliability.

Main varieties

Currently, flexible metal and plastic air ducts for ventilation are being manufactured. Both categories of products are used in the construction of domestic exhaust ventilation systems. Consider the features of the device of these species in more detail.

Plastic channels are made of the following types of polymeric materials:

- Polyvinyl chloride (PVC) with reinforcement of steel spiral is used for the manufacture of ducts with a relatively smooth inner surface.

Flexible PVC channels are made by extrusion on fully automated equipment, and therefore the price of the finished product is relatively low.

PVC channels are not abrasion resistant, but at the same time they are completely transparent, and therefore are the best choice for the device hoods in the woodworking industry. The diameter of PVC products is limited to the size range of 16-200 mm.

Important: A significant disadvantage of polyvinyl chloride air ducts is low resistance to low temperatures, so they cannot be used in intake systems combined with heating. Moreover, such products, when the temperature drops below + 5 ° С, lose their former flexibility and become brittle.

- Viniuretan with reinforcement of steel spiral is used for the production of air ducts according to the principle of welding of a polymer tape together with a metal spiral.

The advantage of such ducts is high resistance to mechanical deformations and extremely low degree of noise. This type of ventilation duct is most flexible. For example, a product can be tied into a knot without compromising its integrity.

Due to the high strength and variety of sizes, these flexible air ducts can be used both for the construction of ventilation and for the connection of air conditioning systems.

- Air ducts made of polyolefin or polyurethane (PU) with steel spiral reinforcement demonstrate average strength. Products can be used in the device of domestic extracts. A significant drawback of such products is the low aerodynamicity of the ribbed inner surface.

Important: Due to the lack of smoothness of the inner walls, air ducts made using these materials are more likely to block up than their counterparts with a smooth inner surface.

Metal products are presented in the following categories:

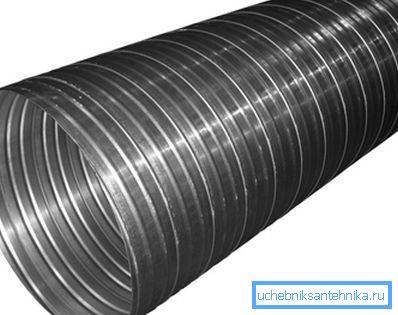

- Steel air ducts for ventilation are made from sheet steel, cut into tapes. The tape is shaped into a spiral, after which a one-piece pipe is produced from the billet.

Such designs are distinguished by a large weight with high strength. For greater durability, the steel is galvanized before the start of production work.

- Aluminum air ducts for ventilation also made of metal strip, from which a round pipe is formed. The resulting ribs are interconnected by a folding lock.

Such products can be bent almost at a right angle without damage to tightness. Moreover, aluminum products, as well as their steel counterparts, are effectively used in the temperature range from -30 ° C to + 300 ° C.

Important: Flexible metal ducts are not the best solution for multiple use. If the ventilation duct is installed and takes the necessary form, it is desirable not to straighten it later.

Operation of flexible ventilation ducts

In accordance with TU 36 736 93 for metal ventilation ducts, these products are used in various industrial fields, in arranging residential and public buildings, etc.

Modern technologies make it possible to manufacture such pipes not only flexible, but also truly airtight. Despite the increased functionality and demand, the price of flexible ducts is not much higher than the cost of rigid analogues.

An important condition ensuring the efficiency of operation of these products is the correctness of the installation work. Moreover, the efficiency of operation of air ducts can be ensured by timely cleaning the internal cavity from blockages.

Consider what are the features of the installation of flexible channels.

Features of the installation work

Connecting metal ducts for ventilation when cornering, in order to achieve optimal tension, you should use metal rigid bends with adjustable angle of rotation. The knee is rigidly mounted on the supporting structures and due to this it is possible to provide the required duct tension on the indirect sections of the line.

This mounting technology provides such advantages as:

- Reducing the resistance of the inner surface of the duct due to the fact that the inner sleeve is properly tensioned.

- The ability to adjust the bend angle in the range of 90-180 degrees;

- Maintaining the required degree of mobility of the ventilation duct during the operation of the system.

- Reliability of fastening a flexible duct when cornering.

- Low probability of breaking the flexible ventilation duct at the turning points.

Important: The use of flexible ducts is subject to a number of restrictions, including the inadmissibility of installation in vertical risers, whose height is more than 6 meters. In addition, flexible channels should not be used without taking into account such parameters as heat resistance, design features, etc.

The installation manual assumes compliance with the following requirements:

- When starting the installation work, it is necessary to fully stretch the inner duct sleeve with your own hands in order to eliminate bends and pressure losses.

- Excess flexible pipes are cut off. Do not install the ventilation system, leaving the extra length of the duct in reserve.

- Suspended brackets are selected taking into account sufficient width in which the outer diameter of the jacket (shell) will not change its shape.

- For the passage of wall structures we will definitely use metal sleeves or adapters that will ensure the safety of the flexible duct during installation and subsequent operation.

Installation work is performed as follows:

- Flexible, temperature-resistant air ducts for ventilation are cut in the stretched state with metal scissors, while the spiral part is bitten by clippers. When working with plastic channels, the polymer shell is cut with a sharp knife, while the helix is bitten off by pliers.

- The connection is made by means of a nipple type coupling, aluminum self-adhesive tape or mastic. The entry of the duct to the nozzle must be at least 50 mm

- Connection for extra strength fix the nylon or metal tie.

- The installation of semi-rigid ducts is carried out by attaching to the flanges and fixing with screws.

- At the end of the work we check the tightness of the connections.

Conclusion

Now you know what PVC air ducts for ventilation and their metal counterparts are. As a result, you will be able to select those modifications of the ventilation ducts that will meet the needs of the air exchange scheme used.

You can find more useful and informative information by watching the video in this article.