Galvanized steel ventilation is a universal solution.

A person faces the question of the proper organization of ventilation both when building a small house in the country, and when erecting industrial workshops, and when arranging office buildings. For each case, you can choose the best ventilation option, but the use of galvanized steel ducts can be considered a universal solution in any situation.

About the benefits of galvanizing

In general, ventilation pipes can be made of such materials:

- plastic - the price of this solution is minimal, but the scope is limited to private construction;

- aluminum - they are corrosion resistant, but aluminum is a rather ductile metal, so that such ventilation ducts do not tolerate possible loads;

- from galvanized steel - practically have no flaws;

- from scrap materials. For example, the air duct can be built even from ordinary thick, well-fitted planks.

Note! Deck vents can be recommended only for ventilation of outbuildings, for example, cellars or basements in the country.

Galvanized ventilation ducts can be used with almost no restrictions. They will easily cope with the transportation of hot air or vapors of aggressive substances. In addition, the steel is able to withstand high temperatures, while maintaining sufficient strength.

Plastic is completely unable to withstand prolonged exposure to elevated temperature, and he can not oppose anything to the effects of chemical substances. The only advantage of this material can be called a small weight and ease of installation.

Galvanized steel ventilation pipes can withstand:

- temperature about +80? С - without time limit;

Note! For the safety of personnel, air ducts transporting hot air are usually equipped with a heat insulating layer.

- for a short time, the air temperature may rise to +200? С. even in case of fire at the enterprise, the ventilation system will not allow the territory to smoke;

- galvanized pipes for ventilation do not require additional protection from moisture. A thin layer of zinc coating prevents corrosion.

Note! Even if the integrity of the zinc layer is compromised, for example, if a screw is inserted, the steel still remains protected. The fact is that steel and zinc form a galvanic couple, and as a result of a chemical reaction, a thin oxide film covers the cut.

Production methods of galvanized ducts

The technology directly depends on the cross-sectional shape of the pipe.

Ventilation pipes can be:

- round section - optimal aerodynamic characteristics;

- square or rectangular section - Aerodynamics is slightly worse, but the profile pipe is easier to install due to flat surfaces.

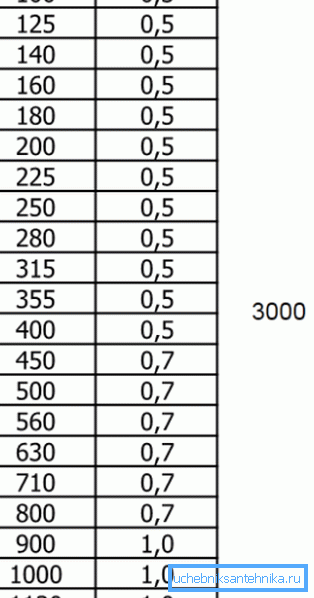

The raw material for the manufacture of galvanized air ducts is thin sheet galvanized steel. As a rule, the sheet thickness does not exceed 1.0 mm; this provides a balance between acceptable weight and sufficiently high rigidity.

The manufacture of ventilation from galvanization is performed by one of 2 methods:

- in the case of a round section, either spiral-wound technology or simple rolling of sheet products with subsequent folding of the edges is used;

- Only one technology is used for profile ducts - a galvanized sheet is passed through a series of rollers, which give it the desired shape. Then the edges of the future ventilation duct are connected.

Spiral wavy technology

Differs in extremely high efficiency, in a minute the machine processes approximately 60 m of strips. The production of galvanized ventilation with this technology consists in the fact that the machine simply bends the steel strip so that a round section pipe is obtained.

At the same time, the adjacent turns are overlapping, due to the strong tension, the edge of the strips is slightly deformed and tightness of the connection is achieved.

In addition to high performance, pipes produced by this technology are distinguished by high rigidity. A screw joint plays the role of a stiffener, so that in equal conditions such ducts will withstand a greater load than its straight-line seam.

Longitudinal pipes

Galvanized ventilation pipes produced by this technology are practically indistinguishable from spiral-wound technical performance indicators. Is that have a little less rigidity.

The whole process can be divided into 3 stages:

- the strip of the necessary length is cut;

- it passes through a series of rollers;

- The adjacent edges of the metal are connected.

As for the profile pipeline, quite often at the ends of the section everything is prepared for the subsequent flange connection. The same technology is used to manufacture ventilation ducts made of galvanized steel.

Elements of galvanized ventilation

When installing the ventilation system, not only galvanized ventilation channels will be needed, but also a number of shaped elements. For example, taps at different angles of rotation, plugs, grids, tees, etc. Without these elements, installation is simply impossible.

Taps

This is one of the most common types of shaped elements, used in cases where you need to ensure a smooth rotation of the duct. The main characteristic of the withdrawal is the angle of rotation, are the options available that provide rotation of an angle of 15? up to 90 ?.

Note! Galvanized ventilation will work much worse if the duct turns many times at a large angle. This reduces the air flow rate.

With regard to the production of taps, it uses a variable width strip. Due to the unequal width when bent, its width of the ring is different. It is theoretically possible to get any angle of withdrawal from several of these rings and the whole tap consists of adjusting the width of the strips, but for convenience they are produced in 15? Steps.

Ventilation box

Strictly speaking, the ventilation duct is just a vertical rectangular or square duct in which several smaller sections are placed. Depending on the operating conditions, plastic, aluminum or galvanized ventilation boxes can be used.

If you mentally cut this construction across, the observer will see not 1, but 3 channels. The largest - a common ventilation duct, and 2 smaller ones - ensure removal of unpleasant odors from the underlying apartment. As a rule, 1 tap is used in the kitchen and 1 in the bathroom or toilet.

Given the small area of the kitchens and bathrooms of most apartments, many people think about how to minimize the area of the box and make it invisible. Galvanized ventilating boxes can help with this.

Note! Residents of multi-storey buildings are often mistaken, considering the ventilation box as their property, and demolishing it. If it comes to trial in court, the would-be builders will have to restore the destroyed with their own hands.

Other fittings

In addition to bends, when installing ventilation, you may need such shaped elements as:

- transitions or ducks - are used to displace the duct. In parallel with the offset by reducing the diameter, you can adjust the speed of the air flow;

- plugs - used if necessary to block the free end of the pipe;

- gate valves - regulating devices;

- fire dampers;

- crosses and tees - are used to create complex nodes of the ventilation network;

- Nipples - used when installing pipes;

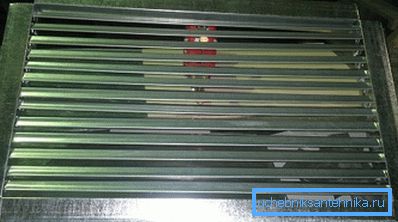

- Galvanized steel ventilation grilles - used to protect insects, small animals and debris from the ventilation channel from entering the room.

About mounting technology

Regarding the mounting of the channel to the walls or ceiling, you can do with ordinary clamps or even just hang the pipe on a metal tape. In industrial buildings for mounting the duct in the wall vsturovaetsya bracket, and the pipe rests on it.

Note! If the speed of the air is high, then fixing the duct with hose clips or with a metal tape will not provide sufficient rigidity. The pipe will rattle, so you need a more secure fit.

Special attention should be paid to the tightness of the joints of individual sections.

A connection can be made in several ways:

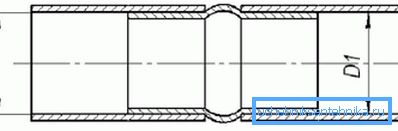

- nipple. The nipple itself - a section of the pipe of a slightly smaller diameter, is simply inserted into the duct with effort and turned. Instructions for making the coupling looks the same, and the only difference is that the diameter of the coupling is larger than the diameter of the duct;

- flange - joint strength is achieved by simply tightening the bolts;

- faltsevoe - reliable joint is provided by the joint deformation of the metal of different sections of pipes.

In conclusion

Ventilation is a guarantee of the normal functioning of any building, both an industrial workshop and a cozy living room in a country house. Currently, there are many materials for the manufacture of air ducts, each of them is good in its own way. This article focuses on galvanized ventilation, perhaps, this material can be called optimal for ducts.

The video in this article describes the process of production of galvanized ventilation pipes.