How to equip the ventilation of the boiler room of a private

Placing a boiler room in their home, some owners neglect the requirements and rules, which may lead to further disastrous consequences. During operation of the boiler in the room creates a rarefied space, which requires a sufficient flow of fresh air, otherwise there is a risk of reverse thrust. Today, our goal is to tell you how the boiler room should be ventilated according to SNiP and show it with an example.

Why do you need it

Do not forget that properly designed air exchange in the room where the boiler is installed is a prerequisite for its operation. If you neglect this aspect, the concentration of carbon monoxide gases in the boiler room can reach sizes that threaten your health, as well as all those living in the house. Methods of circulation of air masses in it can be different and they depend on the type of heating equipment (see also the article Testing Ventilation: tested values and regulatory requirements).

SNiP provides a ventilation system necessary to remove excess heat from equipment and pipelines, as well as to maintain clean air in the work area. When this cannot be accomplished with the natural movement of air currents, the installation of devices capable of forcibly conducting air exchange is required. The price of the system in this case will increase.

Boiler room ventilation rules

When designing a private house, we pay attention to every little thing that may arise in the planning and interior of each room. It is at this stage that the room for the boiler room, which is an essential element, should also be carefully designed.

Although it does not need any special design talents, since all the basic parameters have been regulated for a long time, you should still take the task seriously. Otherwise, you can put yourself at risk of fire, not to mention the fines from fire supervision for violation of work regulations.

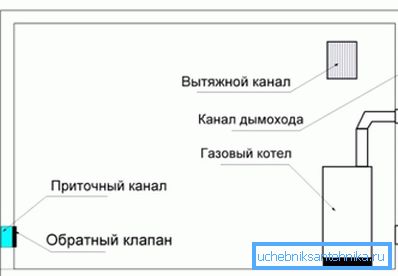

Kinds

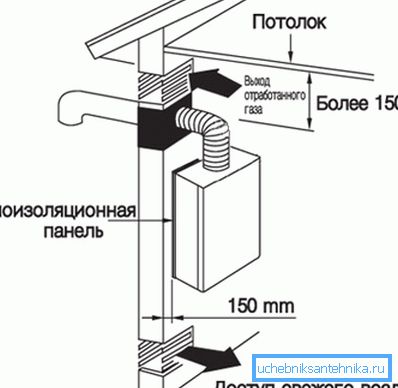

Most often, natural gas is used as a fuel in private homes, for which a constant supply of fresh air is necessary, which is capable of utilizing the combustion products sufficiently. Normal ventilation is usually enough to ensure proper ventilation. In the room where the old doors and windows are installed, air leaks through various gaps.

If the room is more or less sealed, we recommend using additional ventilation. So you can remove from the boiler room the excess combustion products and remnants of unburned gas, traces of which will be clearly visible in the form of soot on the ceiling and walls. However, the unaesthetic appearance of the boiler room is the least of the problems that poor ventilation can create.

| Natural |

|

| Mechanical |

|

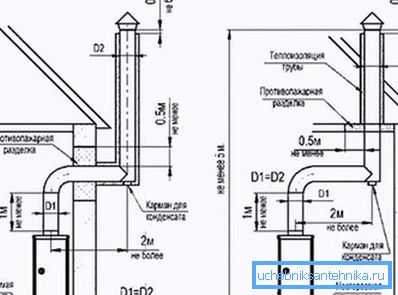

Chimney Requirements

When arranging chimneys of boiler rooms, you should also follow certain rules. Their implementation is also very important for the safe operation of a gas boiler.

Consider the requirements in more detail:

- choosing the diameter of the pipes, it is necessary to follow the equipment manual;

- Do not lift the pipes above the ridge of the roof more than 5 m;

- the installation of umbrellas on chimneys is prohibited;

- the chimney cross-section should be selected in accordance with a specific boiler model;

- the pipe must be cylindrical and made of metal, it is also necessary to provide a hole for cleaning;

- It is forbidden to make more than three bends or turns on the chimney.

Tip: Take seriously all the requirements for installing the chimney, otherwise its improper operation may cause tragic consequences.

How to calculate the ventilation of the boiler room of a private house

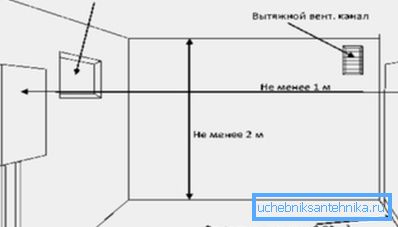

Air exchange in the room must comply with SNiP II-35-76.

It provides for such requirements in boiler rooms where there is no permanent attendant staff:

- When using gas equipment, it is necessary to provide a three-fold exchange of air for 1 hour of the boiler operation. In this case, the volume of air required to maintain the combustion process is not taken into account;

- the height of the boiler room should be 6 m. If this cannot be done, which is most often the case in a private house, it is necessary to increase the air exchange rate by adding 25% for each meter of decrease in this parameter;

- in case of insufficient air flow through the ventilation channels in a natural way, it is necessary to install a forced air exchange system.

These requirements are common for gas and solid fuel boilers. There are only slight differences in the installation locations of the ventilation system.

Tip: before you buy the necessary equipment and install air ducts with your own hands, you should carry out the calculation of the main parameters.

For household boilers, it is possible to simplify the calculation, taking into account the following parameters:

- The volume of the room.

- Air velocity (at least 1 m / s).

- The rate of increase in the rate of air exchange, which depends on the height of the ceilings.

These characteristics will be needed to calculate the required diameter of the air channel.

Example:

- The dimensions of the boiler room are 3x3x2.5 m (width, dyne, height). From here we find the volume, which is equal to 22.5 m ?.

- We calculate the air exchange rate, taking into account the coefficient: (6-2.5) x0.25 + 3 = 3.9.

Accordingly, for 1 hour with natural ventilation should be 3.9 x22.5 = 88 m? of air.

The channel diameter is calculated as follows:

F = 88 m3 / 3600 = 0.024 m2,

after transferring to square in diameter, we get a figure of 88 mm, the closest value of the standard pipe diameter is 100 mm.

In this case, we learned vent ventilation exhaust ventilation, intake must be exactly the same.

Conclusion

It is impossible to ignore the rules and requirements of building codes when arranging a boiler room in a private house, where ventilation plays one of the most important roles. In this article, we talked about the main ones, and also explained with an example how to correctly calculate the ventilation channels to ensure proper air exchange in a room with a gas or solid fuel boiler (see also the article Automatic Control of Ventilation in the Room).

The video in this article will help you find additional information on this topic.