Incubator ventilation and its features

Ventilation is an extremely important factor on which the quantity and quality of chickens released from the eggs in the incubator. The main task of the system is the uniform distribution of heat throughout the incubation chamber, in addition, it performs a number of other important functions.

In this article we will take a closer look at the device of the ventilation system in the incubator and the features of ventilation.

Why is air exchange in an incubator necessary?

With well-organized ventilation, chick output is always greater. Indeed, in addition to its main task, which is mentioned above, air exchange provides the incubation chamber with oxygen, which is so necessary for embryos. In addition, carbon dioxide is released through the ventilation holes, which is released when chickens breathe in the egg.

To understand how important ventilation is, you should familiarize yourself with the schedule for the development of the embryo in the egg:

| 6th day | The fetus begins to absorb oxygen in small quantities. |

| 16th day | Each egg requires at least two and a half liters of air per day. |

| Last day before withdrawal | Each egg requires 8 liters of air. |

If there is not enough air in the incubator, the embryos will start to die. In addition, an important condition for good output is the level of humidity, which also depends on ventilation. Let's talk about humidity in the incubator below.

Features of the ventilation device

First of all, it should be said that ventilation in incubators can be implemented in two ways:

- Permanent - using a fan creates a constant movement of air masses in the incubation chamber, resulting in a gradual change of air. In this case, uniform distribution of heat.

- Periodic - once a day the fan turns on and completely changes the air inside the chamber. At the rest of the time, air exchange is carried out in a natural way.

Note! Even if warm air flows evenly over the eggs, they still need to be periodically reversed. This ensures a uniform distribution of the protein, and also prevents the embryo from sticking to the shell.

Below is a detailed look at both principles of ventilation.

Periodic ventilation

Modern incubators are turned off about once a day and automatically ventilate inside the chamber. If the device is self-made and does not have a similar function, it is necessary to carry out ventilation in manual mode.

Tip! Ventilation in a homemade incubator can also be implemented automatically. For this you need to purchase a special controller.

Ventilation should be as follows:

- Turns off the camera heating.

- At the same time, the fan is turned on, with the help of which the air in the incubator is changed and the eggs are cooled.

- After 15-30 minutes, when the eggs are cooled to 32-34 degrees Celsius, the heating is switched on and off again the fan.

This procedure is very useful for embryos and improves their development.

Continuous ventilation

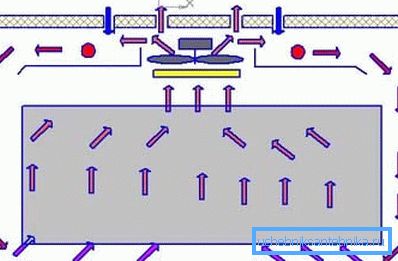

The scheme of continuous ventilation is as follows:

- The fan pumps air from the chamber towards itself, with the result that part of the flow enters the holes located above the impeller and goes outside. The main part of the air masses is reflected from the roof and then passes through the air inlets.

- In the process of movement of the air flow is captured fresh air, which is mixed with the old and passes through the heaters.

- Moving along the walls down, the air flow enters the tray with water, where it is moistened.

- Then the air passes through the trays with eggs and gives them their heat.

- After that, the air re-enters the fan, entraining the exhaust gases.

As a result, such a scheme simultaneously performs heating, ventilation and humidification of eggs. It must be said that in such incubators, the planned cooling of eggs must also be carried out.

Ventilation equipment

As mentioned above, in order for the air exchange to turn on automatically, you will need a controller. In addition, you must equip the device with a fan.

When choosing this device, you need to pay attention to the basic parameters that affect the efficiency of air exchange:

- Diameter - for a small homemade incubator will be enough 80 - 400 mm (depending on the volume of the chamber).

- Ability to work on 220 volts.

- Performance - can range from 40 to 200 cubic meters per hour. The more this value, the better. True, the price of the product also depends on the performance.

Tip! A filter should be installed in front of the fan (shown in yellow in the diagram). If this is not done, then at the output the fan will be clogged with down.

Of course, completely different equipment will be required for arranging a powerful industrial incubator. As a rule, for these purposes, use the supply and exhaust system with a heat exchanger. Such a device allows not only to provide effective air exchange, but also to save energy consumption for heating, since the outgoing air transfers its heat to the incoming heat exchanger.

This equipment is expensive, so it does not make sense to purchase it for private use.

Features of ventilation

Incubation of eggs has a number of nuances that you need to know in order to get a good hatch in an incubator with your own hands. These nuances concern and ventilation. In particular, in the first few days after laying the incubation material, the ventilation system should be closed.

This will prevent excessive cold air from entering the chamber. In addition, due to the retention of moisture in a closed space, the formation of a cold spot is prevented.

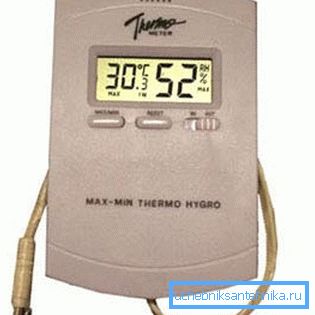

Thus, closing the vents in the first days of incubation will create a homogeneous environment for successful embryonic development. However, it is necessary to make sure that the humidity level does not become too high, i.e. In the first 7–10 days, it did not exceed 75%.

Otherwise, it will be necessary to provide compensatory weight loss in the last days of incubation by low air humidity (less than 40%). This will negatively affect hatchability and chick quality.

Therefore, experts argue that for optimal hatchability during the first 18 days, eggs should lose 11–13% of their initial weight. Weight loss occurs due to the evaporation of water and is directly dependent on ventilation, which removes moisture from the incubator.

The optimal level of relative humidity is 50%. Sometimes experts practice a gradual decrease in humidity from 60 to 45%, but not lower.

As a result, the ventilation manual is as follows:

- Ventilation should begin on the third or fourth day after laying. Moreover, the intensity should be minimal. If you do not start the system in time, there will be a risk of increased humidity over the norm.

- After a few days, the ventilation intensity should be increased and the humidity should be 50%.

- In the future, the humidity level should be stable, respectively, and ventilation works in a constant mode.

Here, perhaps, are all the main features of the organization of air exchange in the incubator.

Conclusion

The quality and quality of the chickens directly depends on the quality of ventilation in the incubator. Therefore, in the manufacture of apparatus, this system must be given no less attention than heating. In addition, as we found out, in the first days after the laying of eggs, it is necessary to use ventilation according to a certain scheme.

From the video in this article, you can get some additional information on this topic.