Industrial ventilation and its features

One of the main conditions for creating comfortable workplaces in industrial premises is the arrangement of an effective ventilation system. It provides fresh air and eliminates contaminated air masses. In this article we will look at how industrial ventilation functions, as well as the main types and features of ventilation systems.

Types of industrial ventilation systems

Depending on the conditions of industrial premises and requirements for ventilation systems, they can be implemented according to the following schemes:

| Natural | It is based on the natural penetration of air into the room and its exhaust through special ventilation ducts. The thrust force depends on the difference in pressure and temperature inside and outside the room. Therefore, the design of industrial ventilation is carried out taking into account the heat emitted by various equipment. |

| Forced | Air exchange occurs due to the use of special supply and exhaust equipment. The effectiveness of this system does not depend on external factors. In addition, it allows you to provide the kind of performance that conditions require in the production area. |

Next, take a closer look at the features of each of these schemes.

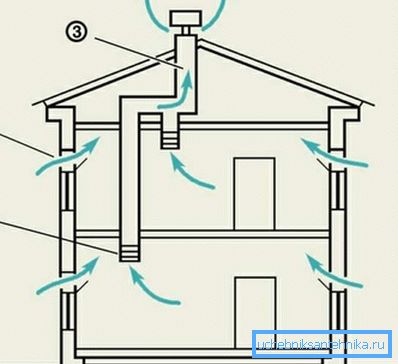

Natural ventilation

Natural air exchange is allowed in those industrial premises where production is not associated with the release of harmful substances into the environment. Such systems imply the presence of ventilation holes, which are located at different heights.

The principle of operation of the natural system is as follows:

- As the cold air descends, fresh air masses enter the room through the holes located at the top.

- Further, the air flow is mixed with the old air and heated.

- Rising up, the air flow exits through the exhaust port.

Air vents allow you to adjust the air through the valves or vents. The advantages of such a system include the fact that it does not require additional costs for electricity. However, despite this, such ventilation is extremely rarely used in industrial premises, which is associated with their low efficiency.

Even if the calculation of industrial ventilation of a natural type is carried out professionally, it will not be enough to ensure a favorable microclimate in a room where emissions of harmful substances are constantly occurring.

Forced ventilation

Industrial ventilation and air conditioning systems are most often performed using special equipment.

This solution has several advantages, such as:

- Large range, as the air masses are fed under the pressure created by the fan.

- The air exchange efficiency, as mentioned above, does not depend on the wind speed and the air temperature outside.

- The ability to heat the supply air currents, as well as expose them to cleaning, moistening or, on the contrary, drying.

- The possibility of organizing an optimal distribution of air masses, for example, with the supply of fresh air directly to workplaces.

- The ability to capture harmful gases directly in the places of their release, preventing their distribution throughout the space of the room, as well as the ability to clean the air flow from pollution before they are released into the atmosphere.

- Installation of forced-type industrial ventilation can be carried out after the construction of the building, while natural ventilation is laid during the construction phase.

Of course, along with the advantages, these systems have some disadvantages, the most serious of which are the following points:

- The high price of equipment, in addition, the operation of the system is associated with certain costs.

- Noisy work that requires some measures to combat noise.

Forced ventilation systems are of several types:

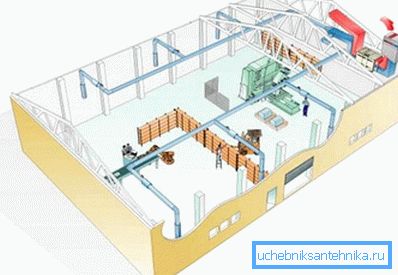

| General exchange | Provide air exchange in all space of the room. Therefore, this ventilation is used in the following cases:

|

| Local | Provide air exchange in a separate area of the room, for example, when you need to clean the air near the source of emission of harmful substances in order to prevent their spread. |

| Mixed | In addition to general air exchange, in some parts of the room local ventilation is carried out. |

As a rule, the volume of incoming air is equal to the volume of the outgoing stream. However, sometimes it is necessary to violate this equality. In this case, the inflow is made larger than the outflow, which allows you to create some excess in the room, for example, to prevent dust from other rooms from entering the “clean” workshops.

In addition, forced ventilation of industrial facilities varies according to the principle of air supply. It happens:

| Inlet | The air intake is carried out using an injection fan, while the outflow is carried out in a natural way by increasing the pressure in the room. |

| Exhaust | Air outflow is forced, and the flow in a natural way due to pressure dilution. |

| Supply and exhaust | This scheme is the most effective, since both the inflow and the exhaust are forced. |

| Recirculating | Polluted air is cleaned, and then re-introduced into the room. Thus, recirculation ventilation is a closed circuit. |

As mentioned above, the choice of air exchange scheme depends on the conditions in the room and production needs.

Ventilation equipment

Industrial ventilation equipment, in fact, differs from domestic only in power.

Moreover, all the basic elements of the system are the same:

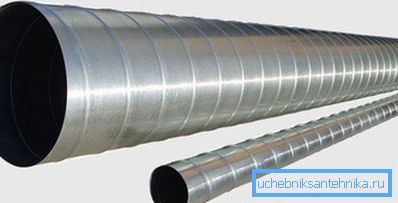

- Ventilation ducts - are pipes of different size and cross-section, which provide transportation of air flow to the place of distribution.

- Shaped parts - allow you to perform turns and branching of the ventilation ducts.

- Fans - are the main element of the forced systems, as they ensure their movement in the right direction under a certain pressure.

- Filters - provide air flow cleaning. They differ in the degree of purification - from coarse, retarding large impurities, to complete, eliminating even unpleasant odors.

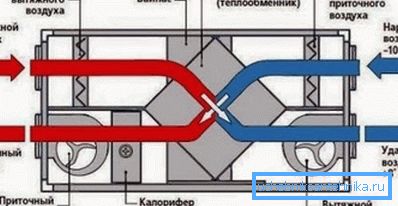

- Recuperators - provide heated air supply with warm exhaust streams. This device allows you to save on space heating.

- Heaters - designed to heat incoming flows in the cold season.

- Air conditioning systems - provide cooling of incoming flows.

Tip! Recuperators are expensive equipment, so it makes sense to use them when servicing large area premises.

It should be noted that ventilation chambers are often used in industrial systems. In fact, these are combined devices that combine all the necessary equipment for ventilation in one case. In particular, manufacturers of industrial ventilation supply them with fans, filters, recuperators, etc.

As a result, for the functioning of the system, it remains only to connect a similar device to the ventilation ducts.

Tip! In some cases, when installing air ducts, non-standard shaped elements may be required. In this case, they can be made independently. The most important thing is to correctly cut the shaped parts of industrial ventilation, after which the parts must be cut out of tin, bent according to the scheme and brewed.

Design features

Designing ventilation of industrial enterprises consists of several main stages:

- Determination of the basic conditions of the premises (their area, configuration features, equipment used, etc.).

- Consideration of climatic features (air temperature, pressure and wind speed).

- The purpose of the room - for example, local ventilation may be required along with a common supply and exhaust system.

On the basis of the data obtained, a calculation is carried out, which includes:

- Determination of duct section;

- Calculation of the frequency of air;

- Determination of the area of the ventilation holes;

- Calculation of power equipment;

- Determining the number of materials required.

It should be noted that the design of ventilation of industrial premises is extremely responsible and at the same time quite a challenge. Therefore, without having certain knowledge, it is not necessary to undertake this work with your own hands.

The choice of materials and installation

In addition to the design, it is very important to choose the right materials for ductwork. For example, at fire and explosive objects it is necessary to use non-combustible materials for installation of channels, for example, galvanized steel. It can also be used in rooms with high temperatures.

If the main requirement is corrosion resistance, for example, when the duct has to work in an aggressive environment or in rooms with high humidity, then it is better to use PVC pipes of the desired diameter.

In areas with a complex configuration of highways using flexible corrugated pipes. However, if it is possible to install hard knees, it is better to give preference to them.

The advantages of the latter are in strength and durability. Corrugation also allows you to assemble the system, even in the most inaccessible places.

Tip! When choosing corrugated pipes, it is better to give preference to steel products, since they are more heat-resistant and have greater strength.

Of course, the installation of the system is not limited to the assembly of ventilation channels. In addition, the installation and connection of equipment.

The assembled system must be tested and adjusted before operation. Instructions for the implementation of these works are also quite complicated, so specialists must also deal with them. Here, perhaps, are all the main features of air exchange in industrial conditions.

Conclusion

Industrial ventilation on the principle of operation does not differ from household, however, its design and device requires a much more careful approach. In addition, for the construction of such systems, special powerful equipment is used, which is able to provide effective air exchange over large areas.

From the video in this article, you can learn some additional information on this topic.