Installation of ventilation for a gas boiler in private

Any heating equipment cannot be operated without good air exchange. Especially important is the ventilation for a gas boiler in a private house. There are no trifles here, because it is about the life and health of people. Incorrect installation can lead to the admission of carbon monoxide into a residential area, which is deadly and has no color, no odor, with all the ensuing consequences.

A few words about the documents

Gathering permits was never a pleasant experience. But, as is well known, all the norms and rules are written on the basis of real mistakes, so their non-observance can lead to big troubles, and the fine is the most innocuous thing that can happen.

The installation of gas equipment in residential areas is regulated by several documents. Firstly, it is SNiP 42-01-2002. As for the ventilation of boiler rooms and furnace rooms in private homes, these requirements are set out in SNiP 11-35-76.

Tip: There is another useful document called Gas supply, based on SNiP 2.04.08-87. At the moment, it is no longer officially valid, but contains a lot of useful information, in addition, on its basis, existing standards were developed.

Highlights and arrangement requirements

Before purchasing the boiler itself and other gas distribution equipment, it is necessary to determine the place of its installation. Perhaps the most important here is the organization of good air exchange.

Requirements

In rooms with gas distribution equipment, in which there is no constant professional supervision, according to the norms, the following rules for the installation of ventilation are adopted.

- For insulated boilers located in residential buildings, complete air exchange for 1 hour should occur at least 3 times.. Moreover, the important point is that these data are derived without taking into account the air flow into the boiler furnace.

- According to the requirements, the ceiling height in the boiler room should be 6m. But in private housing construction it is practically unreal, therefore, for every meter of lowering the ceiling, the air exchange in the room should be increased by 25%.

- As a rule, such a number of air exchange cycles in a small room is very difficult to provide in a natural way, therefore in most cases an artificial inflow should be installed.

Important: these recommendations are true for both gas and solid fuel systems. There is only a slight difference in installation.

Calculation of system parameters

Competently performed calculations are the key to a long and safe operation of the equipment. Professional projects are quite complex, they include the accounting of all parameters. But for private housing, it often turns out to be superfluous, it all comes down to a couple of formulas with which you can calculate the basic data with your own hands.

To find out what diameter of the duct you need to ensure natural air exchange, you need to have the following data.

- First of all, it is the volume of the room itself, which is measured in cubic meters.

- It is also necessary to consider the speed with which the air in the pipe will move; for natural ventilation, this parameter is 1 m / s.

- And the last component is the same rate of increase in the number of air exchange cycles, depending on how much lower the ceiling height compared to the reference 6m.

Next, for clarity, let's consider the calculation of the duct on a specific example.

- Suppose a room has a width of 4, a length of 3m, and the height of the ceilings is 2.7 m. Multiply the data and get the volume of 32.4 m.

- As for the air exchange rate factor, we will calculate it as follows: (6m - 2.7m) x 0.25 (decrease percentage) + 3 (number of cycles for 6m) = 3.8.

- Now we can calculate how much air should come out of this room with natural ventilation in 1 hour: 32.4m? x 3.8 = 123m?

- With this data, we calculate the section of the duct for natural air exchange. To do this, divide 123m ?, into 3600 (the number of seconds in 1 hour). We obtain that the ventilation of a room with a gas boiler must be carried out through a duct of 0.034 m ?.

As you can see, the instruction is quite simple. Often, the ventilation pipes for gas boilers are taken round, as their price is significantly lower. Experts recommend PVC sewer pipes. For the above example, this will be a cross section of 204 mm.

It is often inconvenient and impractical to mount air ducts of large sections. In such cases, standard channels with a cross section of 100-150 mm are mounted and forced pressure is installed on them. The easiest way is to mount intake and exhaust fans of the same power. Depending on the volume of selected equipment power.

Important: the calculation was made for one duct, but in the room there are 2, inflow and exhaust. Both of these channels must be of the same diameter, in this case 204 mm.

Installation Recommendations

It is up to the owner himself to decide on forced or natural ventilation, based on the characteristics of his equipment and the parameters of a particular room. We showed how to carry out the simplest calculations, then you can proceed to the installation of the system itself. There are also limitations and rules.

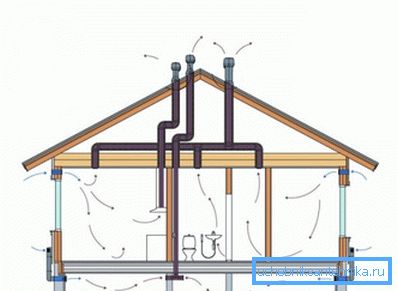

As you know, air ducts can be laid horizontally or vertically. As for horizontal installation, it is valid only for systems with forced injection. Plus, they must be straight, without any twists or turns. The length of the line depends on the parameters and power of the equipment.

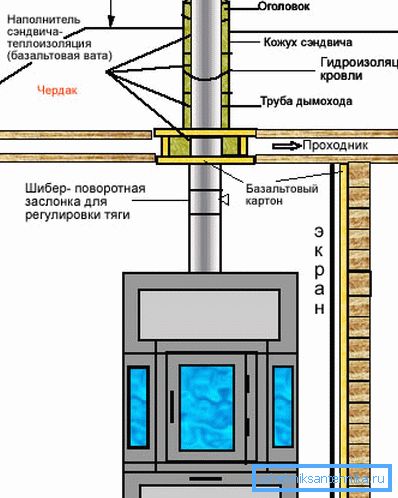

Vertical ducts can be used for both artificial and natural ventilation. The minimum length of a straight vertical channel must be at least 3m. Otherwise, there may be interruptions with a natural burden.

Experts recommend installing a combined system, in case of failure of forced ventilation, you can reduce the load on the equipment. As a result, the system will be able to work with natural air exchange.

Regardless of which system you prefer, the volume of air removed from the room must be equal to the inflow. You should not rely only on the supply fan, you should also install artificial injection on the hood.

The location of the inflow and exhaust is determined depending on where the boiler is located. But the inflow is always done directly near the boiler or behind the unit.

The hood should be placed in the upper part of the room, preferably as close as possible to the ceiling or directly in the ceiling. At the same time, the distance between the inlet and exhaust ducts should be as long as possible. Ideally, diametrically opposed.

For powerful units installed in cottages with a large square and several floors, their ventilation outlet should be separately equipped. As a rule, it has a forced discharge, is mounted on the outer wall of the building and goes above the ridge of the roof.

On the video in this article you can see the details of the installation.

Conclusion

Although the installation of the ventilation system in a private house is not particularly difficult and can be done by hand, the calculation should be taken seriously. If you are not confident in your abilities, you should trust this to professionals.