Installation of ventilation: how to equip the ventilation

In the construction of a private residential building, in addition to running water, sewage, electricity and other engineering networks, it is necessary to provide for the arrangement of the ventilation system. It is a very important factor to ensure comfort and coziness in the house. Installation of ventilation does not make any special difficulties, however, during the work it is important to consider some nuances and peculiarities.

The instructions provided in this article will help you understand them.

Variants of ventilation

Before buying components for the installation of ventilation and to begin its manufacture, it is necessary to understand the principle of its operation and to distinguish between natural and forced schemes of its operation.

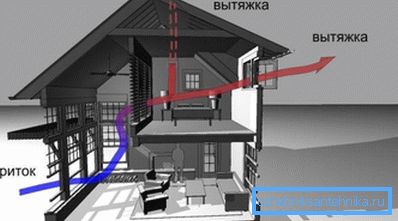

For the organization of effective air exchange in most cases, natural ventilation is sufficient. In this case, the flow and removal of air is due to the difference in pressure and temperature outside and inside the ventilated area.

Despite the fact that the cost of installing ventilation that works on this principle is small, this ventilation system has several drawbacks:

- The effectiveness of its work depends largely on weather conditions. In order for the thrust to form, the indoor temperature must be higher than the outside. Therefore, in the warm season, its performance is greatly reduced.

- To organize the outflow of air, a direct ventilation shaft of sufficiently large cross section and length is necessary. Not in all cases there is the possibility of its manufacture.

These disadvantages are devoid of forced ventilation, where the air flow is organized with the help of fans. However, in this case consumables for the installation of ventilation will cost a bit more expensive, since it will be necessary to purchase various electrical equipment.

Also, the price of its operation will be higher (the power consumption required to power the fan motors will increase).

Note! The work of the forced ventilation system is accompanied by noise. When designing it, among other things, you should take care of high-quality sound insulation, otherwise it will create discomfort to the inhabitants of the house.

Installation of engineering network

Materials used

The quality of the engineering network being constructed directly depends on the ducts used. Their choice depends on the functional purpose of the ventilation system, the area of the ventilated premises and the parameters of the air being moved.

The most common air channels are round and rectangular, made of steel.

Its thickness and coating depends on the chemical composition and temperature of the air passing through the ventilation:

- when the ambient temperature is below + 80 degrees Celsius and humidity up to 60%, galvanized steel with a thickness of 0.5 to 1 mm is used;

- if the parameters of the air environment exceed the above, are used ducts made of stainless or carbon steel with a wall thickness of 2 mm;

- If it is necessary to transport air containing aggressive gases, it is recommended to use in the ventilation system parts made of metal-based or aluminum with a wall thickness of 1.5 to 2 mm.

In addition to direct air channels, modern industry produces many shaped parts that allow you to construct ramifications, contours, turns, and so on.

If an open channel lining is envisaged, you can choose products made of copper, textile or plastic that have an attractive appearance.

Connection types

The air ducts, in order to avoid air leaks, must be interconnected absolutely tightly.

To do this, there are the following methods:

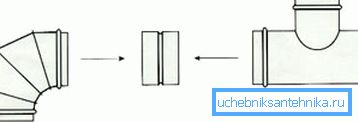

- Flange. It is made from a steel strip or angular steel. It is fixed on the steel duct with flanging.

- Bandage. Special piece that is worn on the air channels with pre-edged edges. To achieve the greatest tightness, the bandage can be filled with hermetic mastic. This method is more often used for designing ventilation systems in chemical production.

- Nippelny (muftovy) connection. Most common in individual construction due to ease of installation. If the nipple is not equipped with a gasket, when installing it, the joint should be additionally sealed with adhesive tape.

- Trumpet. An even more convenient and easy way to dock air channels with each other. In this case, the end of one part is inserted into a specially extended end of the other. Its disadvantage is insufficient tightness, which requires additional efforts to seal the joints.

Installation Features

Instructions for the installation of ventilation is understandable to even an inexperienced master.

Here are a few tips, using which you successfully do all the work with your own hands, getting a reliable and durable system of organizing air exchange in the house:

- Before you begin, you need to decide on the type of fasteners used. For installation of ventilation ducts of small diameter, a mounting vent bracket is suitable. If the project provides for the use of more massive air ducts of large cross-section, a mounting tire for ventilation is required, consisting of a strip and two studs attached to the ceiling. The number of brackets is determined individually, based on the weight, material and length of the air ducts.

- Also, you can not start work without mapping the ventilation network. It is best to draw it on the floor plan of the house. Remember that the air must pass the way from the premises to the economic and auxiliary. Otherwise, polluted air masses from the toilet and kitchen will penetrate into the bedroom and living room, which does not add comfort.

- Do not forget about the supply channels. Installation of a compulsory ventilation system requires at least one duct sucking fresh air from the street. It is also possible to equip the subwindow intake valves with or without fans, which will compensate for the lack of air resulting from its removal.

- When constructing a ventilation network, remember that in the winter, moisture condenses on the inner surface during their work. Therefore, the pipes should be positioned so that the liquid does not get inside the room or on the electrical equipment (fans, heaters, and so on). It is advisable to use special moisture condensers, which will also help fix the tire for mounting ventilation.

- The horizontal sections of the exhaust air ducts must be equipped with exhaust fans without fail. Self thrust is not enough to bring polluted air masses out.

- If the ventilation system you are installing has a branched structure with many inlets, it is necessary to install check valves to prevent the discharge of exhaust air into the living space. Thanks to them, the desired direction of air movement is created.

Note! Safety precautions for the installation of ventilation must be strictly observed. Otherwise, there is a great danger of damage to the equipment and components, as well as serious harm to the health of people involved in the installation of air ducts.

Conclusion

After reviewing the above information, you learned how to install ventilation and air conditioning. Additional information regarding the installation of heat recuperators, filtration plants, control electronics systems, and so on can be found in the video in this article.