Local ventilation: types and calculation

Such a definition, as local ventilation automatically indicates its scope of application - these are separately taken small working areas in production and even in our everyday life. Such exhaust devices are mounted above the work tables, where it is possible to emit any gases, above blacksmith forges and various furnaces, and in everyday life you meet such equipment over cooking (gas or electric) stoves. But such units may differ from each other in the direction of the air flow, and we will talk about this, as well as demonstrate the video in this article.

Ventilation on the ground

Note. If indoors at some place there are emissions of harmful gases and this problem can be solved with the help of general ventilation, then it is often the local ventilation systems that are installed. Their advantage in efficiency - such a device requires less energy, and in addition, the local solution of the problem does not allow gases to spread beyond the workplace.

Kinds

- The most important difference between the types of ventilation for local use is, as already noted, the movement of air flow, therefore, it can be either fresh air or exhaust air..

- Exhaust option is used in cases where it is impossible to prevent the spread of harmful or foul-smelling volatile substances from a localized location throughout the room. The essence of the operation is to capture these same substances by means of the movement of the air flow and throwing them into open space, that is, on the street. In such situations, we are talking about invisible gases, as well as smoke and dust, polluting the nearby space.

- At home, this type of ventilation is familiar to everyone as a kitchen hood. and those who had to disassemble such a unit with their own hands could see one or several fans there. Their blades are turned in such a way that during rotation they seem to suck the air, especially if it rises to the place with a warm stream.

- But local ventilation is used in the form of an air shower., where the colder air flows are directed to any parts or local workplace and for this it is also called blowing. Also, in some factories in the hot workshops, real oases have been created, representing booths 2-2.5 m high, into which cool air is injected, which allows for significant energy savings compared to if the entire workshop had to be cooled.

- But airflow is not always cold, it can also be warm or even hot., for example, such air barriers are created at the furnaces, which in practice looks like a screen through which the furnace heat does not spread (a similar, but weaker effect occurs with a heating radiator located under the window). For blacksmiths and furnaces of various types, aggressive directional air flow helps to maintain combustion or, at higher speeds, increases its intensity.

Note. Both exhaust and intake ventilation can be of two types - individual or central. In the first case, the system is located above one local workplace and has a fairly narrow scope of processing. In the second case, the system can be located above a group of jobs.

Calculation for local exhaust systems

By and large, the calculation of local exhaust ventilation is carried out using formulas and taking into account the many parameters of the room itself, air temperature, harmfulness, engine power, and so on, although this applies only to production, and that is not always the case. But if it comes to calculations, then we will be interested in the exhaust umbrella - it is precisely this that must be taken into account first of all, so that all the harmful substances go up to him, and not near.

The umbrella is the most convenient device for local exhaust, especially for blacksmith forges, cooking stoves, open fire stoves, hot baths, and so on - the heated air rises under the dome itself, where it enters the ventilation duct. Of course, the umbrella, as required by the instructions, should be located as close as possible to the source, in any case, as much as possible.

The starting value for the flow velocity in the working opening of this umbrella is considered to be a value from 0.15 to 1.25 m / s. The speed is directly proportional to the amount of toxic gases and the area of overlap - the more gases and the smaller the dome, the more intense the suction should be.

The capacity of the unit (m3 / h) or the volume of exhaust air is calculated using the formula L = 360abv - here, the symbols a and b mean the perimeter of the working aperture in meters, and the symbol v in the speed of the air flow (m / s) in this aperture.

Separate calculations are also necessary for welding tables and surfacing installations, since it is impossible to hang an exhaust umbrella over such a place (it will simply interfere), therefore, funnel-shaped or slit-like suckers with a length of 250 mm to 350 mm are installed here, depending on the need. In such situations, another formula is used for calculations, which looks like L = ko3vI, here the value of ko is the coefficient for the slot or funnel suction (slot - 12, funnel - 13.2), and the symbol I denotes the welding current in amperes ( BUT).

For the workplace of a welder, this type of ventilation can be performed differently, although, according to the same principle, for example, it can be a pipe with an umbrella connected to the side, but it can also be in the form of a grate on the working table, where gases are sucked in the opposite side. The second option is most favorable for the person working there, as in this case, he practically does not inhale harmful gases. The capacity of the unit for pumping air (m3 / h) should be calculated by the number of electrodes that the welder is able to use for an hour, as well as by the presence of any harmful substances in them.

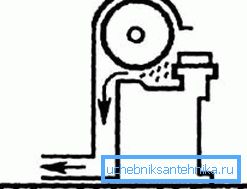

From grinding, grinding and polishing wheels, which are installed on the respective machines, when using them, a lot of dust is emitted, therefore exhaust ventilation at these machines is necessary to preserve the health of workers. To remove dust and small particles of abrasive materials released during operation, the circle is covered with a casing, which, in turn, is connected to an air duct, at the end of which is an exhaust fan of a certain capacity. It is very important that the air channel is directed parallel to the line of movement of dust and abrasive, that is, that this waste flies in the forward direction, without obstacles.

The faster the air flow passes through the duct, the more effective the protective cover will be. But it increases even more if a special visor is mounted in the front part of the casing, which does not allow dust and abrasive particles to rise up (the cost of ventilation will not increase much from the installation of the visor).

The need for a certain ventilation power (capacity in m3 / h) directly depends on the diameter of the circle. Here, the formula L = 1000DA is used - the value of D is the diameter of the circle, and the value of A is the coefficient depending on its diameter. So, if D = 0.25 m, then the coefficient is 2, if D = 0.6 m, then the coefficient will be 1.8, and so on. Between these values you can find the arithmetic average.

Conclusion

You will not need calculations at home, whether it is an extractor hood over a cooking hob or in a home workshop above your workplace. If ready-made units are sold for kitchens, then local ventilation is usually assembled independently in the workshop and its power is usually determined by testing.