Manufacturing of ventilation in a private house: process

For private and multi-storey residential buildings, industrial and public buildings, schools, kindergartens and medical institutions, the manufacture of a ventilation system takes place on the same principle and from the same materials when it comes to metal. The main part of these structures consists of air ducts, which are made on special machines mainly from galvanized sheet steel and aluminum alloys (such pipes can also be made in small quantities in an artisanal way).

In addition to rigid pipes, they also make corrugated pipes, as well as make supply and exhaust umbrellas and slots, tees and corner fittings for turns. All of this below, and to help - the video in this article.

Ventilation

Note. Ventilation systems can be inlet, exhaust and intake-exhaust, each of which can be either natural or mechanical (forced). In addition, intake and exhaust systems can be of general or local purpose. The second option is most often used in production, as the price of energy costs in this case is much lower.

Machine tools

Tubeformer 2020 is a spiral-winding mill made by the Swiss company SPIRO (the price corresponds to the quality of products) for the production of large-sized air ducts, both for the needs of air exchange and for the manufacture of polyurethane foam shells for mines and bridges.

The range of cross-section of manufactured pipes ranges from 80 mm to 2000 mm, with a wall thickness of 0.4 mm to 2.0 mm, but the length of the product is not limited. The machine consumes 11kW, 3380V and 50 Hz of electricity.

Tubeformer 1602 PRO is a spiral-wound mill made by the Swiss company SPIRO for the manufacture of large-sized air ducts, both for the needs of air exchange and for the manufacture of polyurethane foam shells for mines and bridges.

The range of cross-section of manufactured pipes ranges from 80 mm to 1600 mm, with a wall thickness of 0.4 mm to 1.5 mm, but the length of the product is not limited. The machine consumes 15kW, 3380V and 50 Hz of electricity.

Plasmacutter Florett is a plasma cutting machine with a wide range of sheet metal produced by SPIRO and equipped with a computer control program that is customized with your own hands to provide three-dimensional modeling of parts, in particular, exhaust umbrellas, slots and various (round, oval, rectangular) fittings.

The desktop of this model has 30001500 mm, on a common surface of 39902140 mm, traverse, with a speed of movement of 40 mm / min and a cutting accuracy of up to 0.5 mm. At the same time AC Servo 4000I, 50 / 60Hz and 2.5kVA, and Plasma 60A, 230 / 400V, 3 Phases 11kVA, with a total weight of 780kg.

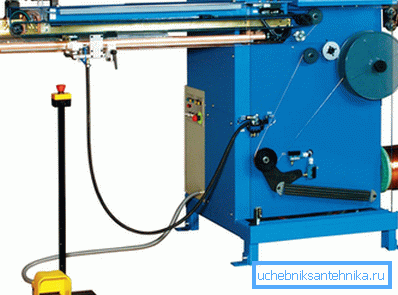

Gorelocker COMBI T, as in the photo above, is a machine for manufacturing segment bends and other fittings made by the Swiss company SPIRO and in this area is recognized as the leader among manufacturers of such equipment.

The outlet diameter is from 125 mm to 1250 mm with a wall thickness from 0.4 mm to 1.5 mm for black steel, from 0.4 mm to 1.0 mm for stainless steel, from 0.4 mm to 1.5 mm for aluminum and from 0.4 mm to 1.25 mm for copper. Power supply parameters 5kVA / 400V / 50Hz, 3 phases.

Stitchwelder 1000/1270/1540 are high-quality seam-welding machines manufactured by the Swiss company SPIRO and used to weld pipes without damaging the front part of the metal being processed. This allows not to resort to hermetic painting products.

Depending on the modification of the unit 1000/1270/1540, the length of the weld can be 50/1000/50-1270/50-1500 mm, overlap 6/8/8 mm, respectively, with a metal thickness of 0.4-1.0 mm, diameter blanks 75-1000 mm. The diameter of the copper wire with a round cross section for welding is 2.0 mm, and the weld welding speed is from 3 m / min to 1212 m / min (instructions for mode selection are attached).

Round and rectangular section

- At industrial enterprises, as a rule, it is the circular section of ventilation that is used - the manufacture of ventilation ducts of this section lowers the aerodynamic resistance when transporting air in the channels, and also, very importantly, significantly reduces the noise level. Isolation of such products is either not spent at all or is minimal, which in both cases saves the budget of the enterprise or organization. To operate the entire system, we do not need too powerful engines for fans, therefore, the economic effect is also observed from this side.

- The density of the joints of such ventilation ducts is very high, which ensures minimal air leakage, therefore, it reduces heat loss. If a company producing such equipment has a complete set of all machines (this article lists only the main ones), then you can order a system of any complexity.

- The main advantage of a rectangle over a circle is its smaller height with the same cross-sectional area, therefore, products with a square section are most often used for installation in low rooms. In addition, a rectangle is easier to place in a smaller decorative box.

Note. For installation of ventilation in a private house, rectangular air ducts are usually used, although some elements may be circular, for example, connecting a kitchen hood with a ventilation window.

Conclusion

In conclusion, we can say a few words about the manufacture of ventilation grilles. They can be rigid and adjustable, with one or two rows of louvers or shutters. Made from plastic, galvanized steel and aluminum alloys.