Operation of ventilation systems: technical requirements and

The topic of this article is the rules of operation of ventilation systems. We will have to study the existing regulatory documents, which stipulate both the technical aspects of the maintenance of ventilation and the limitations associated with the safety of work in enterprises.

So let's get started.

Foreword

The requirements for commissioning, maintenance of ventilation, the order of its on and off since the Soviet era remained somewhat ambiguous situation. Each ministry issued its own regulatory document with its own individual list of recommendations. Any general rules that are relevant to any ventilation system simply do not exist.

Please note: the reason for this is not the inclination of officials to excessively bureaucratize someone else’s work. Agree that the requirements for defense enterprises, the production of toxic insecticidal drugs and, say, for the post office will inevitably differ.

Here are some examples of industry documents.

- In 1977, the Ministry of Communications approved the Instructions for the operation of ventilation and air conditioning systems at communication enterprises.

- In 1997, RAO United Energy Systems of Russia issued a model instruction manual for the operation of heating and ventilation of thermal power plants.

- 1983 dates from the recommendations adopted by the Ministry of Transport Construction for the design, installation and operation of ventilation systems in the construction of tunnels.

The object for our study will be a relatively old, dating from 1974 and retaining relevance in our time a document called BCH 316-73. It was chosen because the requirements and recommendations set forth in it are quite universal: the instruction manual for the ventilation devices of industrial enterprises of the Minmontazhspetsstroy is not tied to any highly specialized production conditions.

In addition to operational requirements, we will address restrictions related to occupational safety at work. They are exhaustively described in GOST 12.4.021-75 Occupational safety standards system. Ventilation systems: general requirements.

BCH 316-73

The instruction manual for the ventilation systems is divided into several thematic sections. We will study them in the same order in which they are presented in the document.

Organization of operational services

Responsibility for the condition and efficiency of ventilation is assigned to the chief engineer; The technical management of the operation and repair is carried out by the chief power engineer (chief mechanic) of the enterprise.

The maintenance service deals with:

- Development of work instructions for each individual production site;

- Monitoring compliance with these instructions;

- Verification of compliance with the actual performance of ventilation design standards;

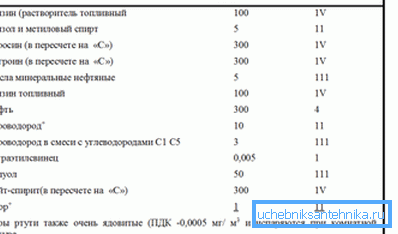

- Monitoring compliance with sanitary standards (in particular, on the limiting concentrations of potentially harmful substances). For periodic checks of the composition of the air, employees of the chemical laboratory of the enterprise or third-party organizations are involved;

- Drawing up technical documentation for scheduled repair and reconstruction of ventilation;

- Supervision of the technical condition of the equipment.

In the staff list of the department of the main power engineer, the staff unit is personally responsible for the work of ventilation. Position is determined by the number of repair units of equipment:

| The number of repair units of ventilation equipment in the enterprise | Position responsible |

| Less than 600 | Ventilation Brigadier |

| 600 - 1250 | Ventilation Master |

| Over 1250 | Ventilation engineer |

On and off

The intake and general exchange exhaust fans are turned on 10-15 minutes before the start of the work shift. The order of inclusion must be strictly defined: first, the hood is turned on, then the inflow.

Switching off is performed 10-20 minutes after the end of the shift in the reverse order: the hood is turned off after flushing. If the company is equipped with a heating and ventilation unit, then after the end of the work shift, it is transferred from the air exchange mode with the street to the recirculation mode.

Local exhaust hoods (umbrellas over the machines, welding zone, etc.) are switched on 3-5 minutes before the beginning of the shift and off after 3-5 minutes after its completion. When the supply air is stopped for a long time (for the duration of the ventilation repair or when production is stopped), the water is completely drained from the heaters.

The price of non-compliance with this requirement is a high probability of defrosting the circuit in winter.

An important point: to drain the circuit, you need not only to open the vents in its lower part, but also to open the vent at the top. Without air leaks, the coolant will inevitably hang in the pipes.

Explosion and fire hazardous production

- All work with ventilation is carried out only with the permission of the foreman.

- The ventilation chambers are checked by the ventilation workers at least once per shift with the obligatory recording of the inspection results in a journal. All defects that can lead to the accumulation of flammable or explosive substances are eliminated immediately after their detection.

- Air ducts, dust separators, chambers and filters are periodically cleaned from dust, other contaminants and combustible objects. The cleaning time is recorded in writing.

- Storage of any materials and tools in the rooms of ventilation units is prohibited.

- All work on the repair and reconstruction of ventilation is carried out during off-hours (preferably on weekends) after cleaning the equipment from flammable and explosive deposits. For the repair, the written permission of the workshop or shift supervisor is required.

- Fire-retardant valves in the wall must be securely without gaps, sealed with mortar. The valves themselves are periodically cleaned and lubricated if necessary.

- In case of fire, the ventilation stops and all valves are moved to the closed position.

Fans

Fans should have a smooth and silent as possible. Strong vibration in the process of work is unacceptable.

The direction of rotation of the radial fans must match the shape of the cochlea.

Hint: the direction of rotation of the closed impeller is easily determined by the free end of the axis of the electric motor.

The impeller blades should not have visible deformations that can lead to a beating. Infringement of balancing is also prohibited. It is easy to check the balance by spinning the impeller a few times with your own hands: it should stop in different positions, and not only in the initial position.

The impeller should rotate freely by hand, without touching the casing. The bolts securing the fan casing to the base must be securely tightened. The presence of lock nuts required

The maximum allowable amount of beating of the impeller fan depends on its size:

| Fan number (equal to the impeller diameter in decimeters) | Radial beating, mm | Axial thrust, mm |

| 2 - 6.3 | one | 2 |

| 6.3 - 12.5 | 2 | 3 |

| Over 12.5 | 3.5 | five |

The gap between the impeller and the suction nozzle of the centrifugal fan should not exceed 1% of the diameter. The gap between the impeller and the shell at the axial fan is limited to 0.5% of the diameter.

Bearings must be inspected and lubricated:

- When pouring mineral oil - at least once a month.

- When using thick lubricants (grease, etc.) - at least every 3-4 months.

Replacing the lubricant with flushing the bearing housing with gasoline should be carried out:

- For mineral oil - at least every six months.

- For thick lubricants - at least once a year.

Important: the temperature of the bearing housing should not exceed 70C. If this value is exceeded, the bearing requires flushing and lubrication.

Impellers and housings need periodic cleaning from dust. When they are quickly contaminated, the covers should be provided with airtight hatches for cleaning.

Electric motors

The motor housing must be grounded.

The power supply to the motor immediately stops under the following conditions:

- Accident related to the operation of the ventilation equipment.

- Strong vibration. She most likely talks about the destruction of the bearing.

- Detected fan failure.

- Strongly heated motor housing or bearings.

- Smoke or fire from the motor itself or its starter.

Heaters

They are periodically cleaned with compressed air powered from a highway or cylinder.

In the presence of coarse filters in the contours of the heaters, they need periodic cleaning and washing of the nets.

If leaks occur on flanges or covers, gaskets must be replaced. At the working temperature up to 100 ° C, the gasket board boiled in linseed oil is used; at temperatures above 100 ° C - paronite (hard heat-resistant rubber). New gaskets before installation rubbed with graphite.

Air ducts

The condition of the bolts on the flange connections should be periodically checked. All bolts must be fully tightened; the nuts must be located on one side of the flange.

Air ducts transporting air with aggressive gases or vapors need to be periodically checked for tightness. Hatches, manholes, holes for cleaning should be tightly closed.

If a flange joint is leaking, it is moved and the gasket is replaced. At temperatures up to 70 ° C, porous or monolithic rubber is used; at a working temperature of 70 ° C and above, asbestos cord or asbestos cardboard should be used.

GOST 12.4.021-75

In this standard, as we recall, contains instructions for the operation of ventilation systems related to safety at work.

Some of its points partially duplicate the previous document; not to repeat, we will exclude them from consideration.

- The rooms in which the ventilation equipment is located must be locked. Doors are marked with signs prohibiting entry for unauthorized persons.

- The thickness of the walls of the air ducts in contact with aggressive media is checked at least once a year.

- Flame retardant valves are also checked at least once a year. The results of the inspection and verification are recorded in the passport of each device.

- Bearing lubrication is carried out only after a full stop and de-energizing the devices.

- Methods for cleaning air ducts, impellers and housings for fans, filters and chambers at fire-hazardous and explosive industries should exclude the possibility of explosion or ignition of accumulated materials.

Conclusion

We hope that our brief review of existing regulatory documents will be useful to the reader. As usual, in the attached video in this article you can find additional thematic materials (see also the article “The project of ventilation: stages of development”).

Successes!