Passport of the ventilation system: the purpose of receipt,

What is the certification of ventilation systems? What are the requirements for ventilation by current regulations? What should be the passport of the ventilation system for SNiP?

Let's try to answer these questions.

What it is

The passport of the ventilation system is a document establishing the legal right for its commissioning. He confirms that the entire cycle of works - the drafting of the project, the installation of equipment and its commissioning - were carried out in full compliance with the current regulatory and technical documentation (see also the article “Roof ventilation” is a simple but important step in home improvement).

What is it for?

- For official registration of purchased equipment. Even if the air handling unit or another ventilation element is purchased abroad and does not have domestic certification, the ventilation passport will certify its compliance with current requirements.

- To argue your position in any disputes with supervisory authorities. For example, in case of a building smoke, the owner will always be able to prove that the cause could not be caused by malfunctions or imperfect ventilation equipment.

Important: even if you have all the certificates for equipment that complies with national GOST, you will receive a passport of the ventilation unit only on the basis of a set of tests.

Regulatory requirements

What requirements must the ventilation system itself meet? What do her tests look like? Most of the information we are interested in can be found in SNiP 3.05.01-85.

Requirements for ventilation and air conditioning systems

Air ducts are installed in accordance with the project, regardless of whether the contractor has the necessary equipment for installation work at the desired height and using the selected technology. Simply put, explaining that the ventilation channel has shifted down due to the lack of scaffolding of the required height does not touch anyone.

If the air duct transports air with high humidity, there should be no longitudinal seams in its lower part. Areas where dew may fall are laid with a slope to the drainage; slope should be taken equal to 1 - 1.5 cm per linear meter of length.

When flange joining parts of the gasket on the flanges may protrude outward, but not inward. Gasket material is regulated depending on temperature conditions:

| Air temperature | Sealing materials |

| Up to 70C | Foam rubber; porous or monolithic rubber (thickness 4-5 mm); polymer mastic rope |

| Over 70С | Asbestos cord; asbestos cardboard |

Important: if the production conditions involve the transport of air saturated with vapors of acids, acid-resistant rubber or plastic is used as gaskets.

For flangeless joints, the list of sealing materials is also negotiated depending on the conditions:

| Conditions | Applicable Materials |

| Temperature up to 40С | Gerlen sealing tape |

| Temperature up to 70C with a round section of the duct | Mastic Buteprol |

| Temperature up to 60 ° C with a round section of the duct | Shrink Cuffs |

All bolts on the flanges must be tightened. Nuts are located on one side of the flange. With the vertical orientation of the flange their location is not regulated; with horizontal orientation it is recommended to place the nuts on the bottom.

The duct attachment points (suspensions or supports) can be located:

- With a flangeless connection and the largest size (diameter or side) less than 400 mm - with a maximum step of 4 meters.

- With a flangeless connection and the largest size of more than 400 mm - in 3 meter increments.

- With a flange connection and the largest size of 2000 mm - with a pitch of 6 meters. In this case, suspensions and extensions should not be attached directly to the flange.

- With the vertical orientation of the duct - in increments of no more than 4 meters.

Nuance: when the height of the floor is less than 4 meters, the vertical channel is fixed in the ceiling. The maximum allowable deviation from the vertical is 2 mm per linear meter.

The air ducts are connected to the fans with flexible inserts, excluding the transmission of vibration. As a rule, fiberglass sleeves are used in this quality. Vibration inserts are installed in the last installation, just before the tests.

When assembling the vertical bell-shaped canal, the sockets should face upwards. Hemp harnesses impregnated with asbestos-cement solution with casein glue are used to seal the socket. The remaining cavities are filled with asbestos cement mastic.

After the mastic has hardened, the joint is pasted over with a cloth and painted with oil paint. Radial fans are attached to the foundations and anti-vibration bases with anchor bolts. At the same time, vibration isolators themselves are not attached to the floor; but when they are installed on the metalwork fixation is necessary.

The gap between the suction nozzle of the radial fan and its impeller must not exceed 1% of the wheel diameter. The shaft of the radial fan should be strictly horizontal. Vertical orientation is necessary only for fans mounted on the roofs of buildings.

When mounting the fans, the electric motor and the impeller must be strictly aligned. When using belt gears, pulley axles are mounted in parallel. Motor skids are mounted horizontally, level, and touch the base of the whole plane.

Couplings and belts between the electric motor and the working part of the fan are guarded by protective covers. Protected by a metal grid with a mesh size of not more than 70x70 mm and the suction nozzle of the fan, not connected to the duct.

Industrial air heaters and air conditioners are installed strictly horizontally and mounted on rubber gaskets; their bodies and main assemblies are assembled with a strip of rubber 3–4 millimeters thick. The instruction is designed to prevent the transmission of vibration to the walls of the building and other equipment.

Ventilation valves should open and close with minimal effort, so that they can be easily turned with their own hands, without levers and tools. In the closed position, the valves of the valves should fit snugly to the stops.

Test requirements

As we remember, the certification of ventilation systems implies their testing.

How are they carried out?

- The design and condition of the ventilation systems are checked for compliance with the working draft and the requirements outlined above.

- Checked for tightness hidden areas of air ducts.

- All equipment having its own drive, dampers and valves is checked at idle.

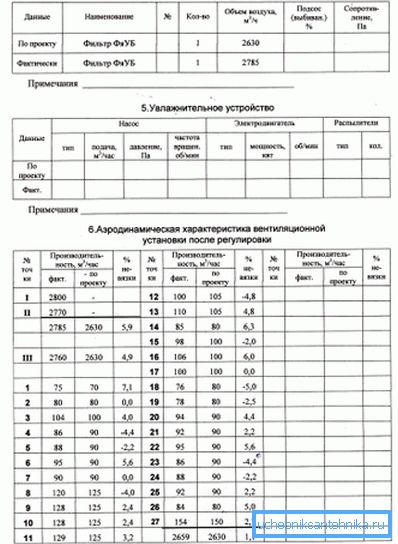

- For fans, they are checked for compliance with the declared passport data (revolutions, air flow, generated pressure).

- The efficiency of air exchange as a whole and its compliance with the project is assessed. Among other things, certification of ventilation requires verification of the natural circulation of air.

- The noise level is measured at several design points of the room.

The maximum deviation from the design air flow, which does not interfere with obtaining a passport for the ventilation system, can be + 10%, provided that the air flow into the premises is adequate.

The form

What data should contain a passport to the ventilation system? The answer can be found in Appendix 2 to the same SNiP 3.05.01-85.

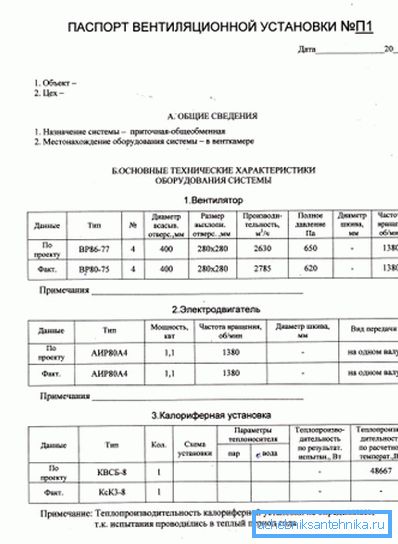

General information

- The object and its location.

- The purpose of the ventilation system and the location of the equipment.

Characteristics of the equipment

For fans are indicated:

- Type of.

- The diameter of the impeller.

- Air flow.

- Total pressure

- Rotation frequency.

- For devices with a belt drive - the diameter of the pulley.

For electric motors:

- Type of.

- Power.

- Rotation frequency.

- Type of transmission.

- Pulley diameter (if available).

For heating and air conditioning equipment:

- Type of.

- Circulation of the coolant and air.

- Type of coolant.

- The test results of heat exchangers for working pressure.

For filters:

- Air flow.

- The percentage of capture.

- Resistance to air flow.

For humidifiers:

- Type of.

- Air flow.

- Pressure before the sprayer.

- The frequency of rotation of the motor and impeller spray.

- Its type and power.

In addition: the dimensions of the duct sections, the actual air consumption and its compliance with the project are indicated in the passport.

The cost of certification of ventilation systems starts from 3-4 thousand rubles and, for obvious reasons, strongly depends on the complexity of the system. Some organizations prefer to evaluate their work on the area of the ventilated room. In this case, the price varies from 50 to 100 rubles per square meter.

Conclusion

We hope that we were able to answer all the questions that have accumulated in the reader (also read the article Ventilation valve - views and features).

As always, a certain amount of additional thematic information can be found in the video in this article. Successes!