Plastic ventilation duct - types, characteristics and

When making a choice between metal and plastic ventilation, many homeowners doubt the reliability of the latter, although its low weight greatly attracts them. Today, synthetic material is used in many areas of our activity, thanks to which it is possible to reduce the mass of objects that have recently been bulky and heavy. Today we will look in detail at what a plastic vent is, where it is used and what its features are.

Beauty and practicality

If we take the conditions of our present reality, in a private house plastic ventilation is more profitable than galvanized or aluminum air ducts. It can be round or rectangular, and also differs in its appearance.

The consumer is given the opportunity to choose products from a large range of colors that will be in harmony with the interior of the house. The price of plastic ducts is significantly lower than metal counterparts, and the installation is extremely simple and accessible even to a non-professional.

Plastic ventilation pipes in recent years have been able to become leaders in terms of production and sales. In fact, this indicates that buyers had time to evaluate their reliability and ease of use.

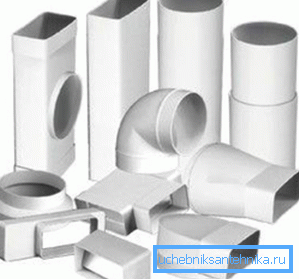

In addition to pipes for air ducts, other elements of the plastic ventilation system are also offered to consumers, including:

- adapters;

- couplings;

- caps;

- lattice.

Shaped elements of the appropriate form make it possible to connect rectangular in cross-section of air ducts with round ones.

Materials used for plastic ventilation have their own characteristics:

- polyethylene - flexible and durable;

- polyvinyl chloride - resistant to flammability and insensitive to UV radiation;

- polypropylene - it has good strength and chemical inertness to aggressive media.

Pros and cons of plastic ducts

In the past, galvanized tin or aluminum was the most common material for ventilation ducts in private homes (quite rarely). When manufacturers offered an alternative to customers - plastic ventilation pipes, the preferences of engineers and owners of private houses were given to them.

Below we consider the advantages in more detail:

| Corrosion Resistance | The structure of the material is such that there is nothing to rust in it. Therefore, such a vent exhaust pipe will be indispensable in conditions of constant humidity in the room. |

| Inner surface |

|

| Weight | Even if you need to transport a lot of ventilation pipes and fittings, you do not need to order a multi-ton truck. The weight of the products is so small that whatever their size, they can easily be lifted and turned with their own hands during the installation of the ventilation system. |

| Installation and operation | Installation of parts and assemblies is much easier than installing heavy metal boxes. Periodic prevention and cleaning of the ventilation channels will also not be difficult. |

| Cost of | The low cost of plastics compared to metal can significantly reduce the cost of the ventilation system. |

Tip: do not use plastic pipes in an environment where the air temperature may exceed 80–90? С, for example, in a sauna, bakery or boiler room.

Shape and size

Usually in private homes, ventilation is made of round or rectangular pipes. There is also an intermediate option - with oval.

Round air ducts can be rigid and smooth, as well as corrugated, due to their flexibility it is possible to make installation of complex ventilation channels. The choice of form depends on the location of the duct, but also on the design project, which is of no small importance.

Manufacturers produce plastic ventilation pipes of standard sizes. This unification allows you to quickly pick up to them the necessary accessories. We recommend to use pipes 2.5 m long for laying air ducts in the cottage, which makes it possible to carry out the installation without using unnecessary connections.

Tip: when drawing up a ventilation plan, remember that the throughput capacity of a rectangular ventilation channel will be slightly lower than that of a round one due to the resistance created.

Layout of ventilation in the house

If you have never dealt with such issues before, we recommend that you seek the help of specialists to help them correctly position the elements of the hood. In addition, the correct calculation of system performance will be of great importance, otherwise the power of the devices may simply not be enough for their comfortable work.

In the end, the result will not satisfy you and you will have to redo everything anew.

To prevent this, discuss the following with the wizard:

- distribution of exhaust holes - for each room (bathroom, living room, kitchen) it is necessary to make a separate duct;

- Condensate drain - through time, moisture will begin to accumulate in the ventilation pipes, therefore, although plastic is not afraid of water, therefore special holes should be made for its removal;

- placing additional devices on long sections - in this case we recommend to equip horizontal pipelines with additional electric fans, which will work to bring exhaust air out of the premises.

Tip: install a check valve in the necessary places of the system, then the electric fan will not drive air in vain from one room to another.

When constructing ventilation from plastic pipes, it is also necessary to use various turns, couplings and tees to connect them. However, we recommend counting the gasket so that each box lies as flat as possible and with the least amount of turns. Make sure that there are not too many joints in the duct system, it is better to use solid pipes as much as possible.

The optimal configuration of the ventilation channels allows you to:

- increase the speed of the air flow and reduce noise if there are fewer sharp turns and junctions;

- reduce overall costs, as you do not have to spend money on numerous fittings.

The size and shape of plastic pipes for ventilation inside the room should be selected after the drafting. For example, with open laying of air channels, you can focus on the color of the interior. Although very often homeowners seek to hide any air duct under a decorative casing or ceiling.

Another thing - exhaust kitchen pipe, which often goes openly. In this case, we recommend to color it in the chosen color for the design harmony. In the kitchen to carry out ventilation is not difficult on their own.

Tip: treat the inside of the plastic pipe with an antistatic compound so that dust does not stick to the plastic, fat drops and static electricity does not accumulate on it.

How to assemble plastic pipe ventilation

The assembly process will not cause difficulties for those who are at least a little familiar with conventional construction tools.

The instructions below will help to deal with the work in more detail:

- Cut plastic pipes into pieces at the installation site.

- For the connection, you can use two methods - one-piece (with welding) and detachable (with flanges and fittings). We recommend the second option in order to facilitate the task of repair.

- Connect the elements of the duct and fasten them using the supplied fasteners and silicone sealant.

- Assemble the structurally complex components of the ventilation system on the floor, and then lift them to the place of installation.

- Fix the air ducts to the ceiling with special clamps. Since their weight is small, one attachment per piece is sufficient. If you use large and heavy plastic rectangular boxes, you will have to fix them every 1.5 m.

Tip: to verify that the ventilation system is installed correctly, pay attention to whether windows in the cold weather sweat at home. If not, then you did everything right, otherwise the mistakes were made at the design stage.

Conclusion

This article was devoted to the ventilation of plastic pipes. Its basis is - round, oval or flat ventilation duct with connecting fittings. It has its advantages - it does not rust, it has a small weight, and also disadvantages - it can not be used at air temperatures above 80-90? С.

The video in this article will help you find additional information on this topic.