Plastic ventilation is all about perspective material.

There were times when the vast majority of air ducts were metal irretrievably gone. Nowadays, plastic ventilation is becoming increasingly common, and there is a logical explanation for this - in terms of performance, a plastic duct is almost as good as a metal one, with several advantages.

Reasons for popularity

In general, it is allowed to use:

- metal ventilation (either galvanized steel or aluminum is used);

- asbestos pipes;

- plastic air ducts for ventilation - in this case, special attention is paid to the fire safety rules.

Plastic is quite popular for several reasons:

- its inner surface is perfectly smooth, so that the resistance to air flow is minimal;

- plastic is a fairly light material, and since the special strength of the duct is not needed, even a small wall thickness is sufficient;

- Special plastic with antistatic properties is produced for air ducts, so that the dust does not settle on the inner surface, therefore, such pipes need to be much less frequently than an ordinary steel pipe;

- This material is very easy to handle, so when installing, you can always cut the desired piece of pipe with a regular hacksaw;

- absolute indifference to moisture can also be added to the asset of this material.

As for the shortcomings, only one significant negative can be identified - low resistance to high temperature. In addition, the price of high-quality plastic pipes (with antistatic coating) may exceed the cost of ordinary galvanized, so that the relevance of such a decision may be questionable.

Application area

As for the possibility of using plastic ducts for organizing ventilation, the experts did not come to a common opinion.

You can say the following:

- at the industrial enterprises there is no place for plastic. This material is not comparable with the metal in strength and resistance to high temperatures. In addition, small particles of abrasive may be contained in the air, and plastic ventilation systems have poor resistance to abrasion;

- even in home ventilation systems such material cannot be used, for example, as a kitchen hood. The reason is still the same - poor resistance to heat;

Note! You can find mention of plastic that can withstand high temperatures, but you need to understand that all the same, when heated, there will be a decrease in strength and the duct may simply not sustain its own weight.

- quite often, the vaunted antistatic coating does not fulfill its function, and the pipe is actively overgrown with dust, no worse than the metal one;

- At the same time, SNiP 31-02-2001 for small houses (if their height does not exceed 2 floors) does not put forward special requirements for fire resistance and fire safety. Therefore, plastic ventilation in private construction can be used at the request of the owner, but in apartment buildings you need to take into account the fire resistance class.

Plastic ventilation elements

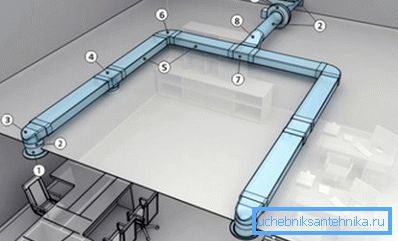

Not only the air ducts themselves are made of plastic, but also all shaped elements.

For the installation of ventilation systems will need:

- the pipes themselves;

- check valves;

- tees for the device of complex nodes;

- hatches;

- transitions.

Plastic air ducts

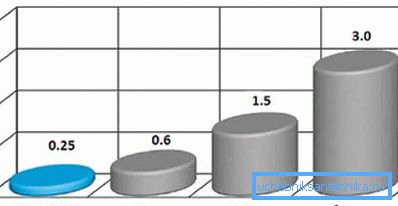

The dimensions of the plastic air ducts for ventilation are selected on the basis of the required air exchange and the speed of the air flow. Also, when choosing, it is necessary to take into account the shape of the ventilation channel, there are traditional round pipes for sale and square or rectangular versions.

Usually the shape of the pipeline is chosen based on the method of installation and the type of ventilation.

The following considerations are guided by this:

- round duct is more difficult to disguise behind a partition (for example, behind a suspended ceiling). If we compare a rectangular and a round pipe, then the height of a rectangular section will be less than the diameter of a round pipe, and the area of the pipes will be the same. Saving even 20-30 mm can be invaluable;

- when the installation is done by hand, rectangular pipes are preferable, they are easy to put in the upper corner of the room and then hidden behind a multi-level suspended ceiling;

- but from the point of view of aerodynamics round pipes are out of competition. In the profile duct dust will accumulate more actively;

- besides, plastic rectangular ventilation will not allow installing a duct fan in the duct.

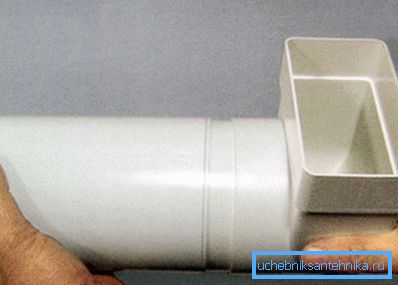

Plastic transitions

This element is necessary in 2 cases:

- when it is necessary to ensure the connection of 2 ventilation channels of different cross-section (sometimes, when laying ventilation channels, both round and square / rectangular pipes are used);

- if necessary, ensure the connection of 2 pipes of different sizes.

Externally, plastic transitions for ventilation look like a truncated 4-angle pyramid or a truncated cone (when 2 square / rectangular ducts are connected). In rooms with a complex geometry, transitions with an offset are sometimes used — in this case, both holes are not on the same axis.

Note! Transitions with an offset are used in cases where the 2 sections of the duct are slightly displaced relative to each other and there is no point between them to lay an additional section of pipe.

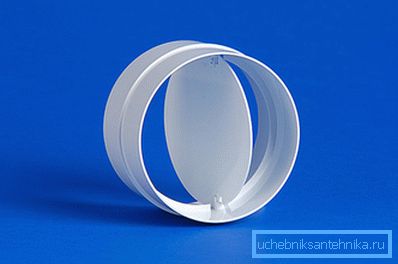

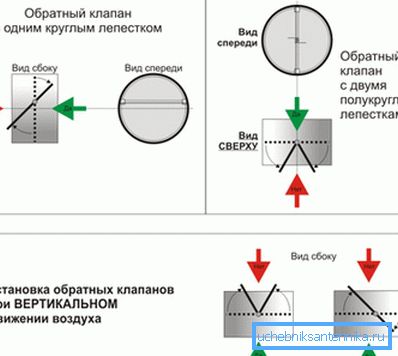

Check valve

This device can be attributed to the category that are used to improve ventilation and eliminate some of the problems with its functioning. As a rule, they are installed in the duct in order to solve the problem with the reverse of the plunge.

For example, in the kitchen there is an excessively powerful hood that, when turned on, not only polluted air from the kitchen is pulled out, but also causes the craving to disappear in other rooms. Most often this is accompanied by the entry of polluted air into the rooms. A plastic check valve for ventilation can solve this problem.

It can be imagined as a frame in which a blade is fixed on the axis, in the closed state completely blocking the duct, this blade can open only in one direction. When the thrust is normal, then nothing interferes with the air exchange; in the event of a reverse thrust, the ventilation channel is blocked.

Note! If the channel in the channel is constantly small, then these valves can be used as control valves.

Other components

In addition to those already listed, you will need such plastic components for ventilation as:

- elbows - are used in cases where the ventilation channel changes direction, they can be both round and square / rectangular. Provide a smooth rotation at an angle of up to 90 ?;

- hatches - plastic plastic ventilation hatches are used to facilitate access to communications;

- such shaped elements as tees will be needed in complex branched ventilation systems.

Note! Plastic tees for ventilation require increased attention to the calculation of the ventilation system. In the case when at one point converge, for example, 2 exhaust ventilation channels it is necessary to ensure that none of them “overtighten” the other.

- lattices - The exit from the duct into the room is usually closed with a grill.

About the installation of plastic ventilation

Installation of plastic ventilation should not cause any particular difficulties.

Instructions for performing work looks like this:

- if a pipe was cut, then any burrs need to be removed, the cutting edge should be perpendicular to the longitudinal axis of the ventilation channel;

- In order to connect the individual pieces of the ventilation duct into one piece, plastic couplings are used (as a rule, they are included in the delivery package). Some, to guarantee tightness, coat the joint with sealant and even screw the screws into the sleeve, but this is an unnecessary measure. Moreover, such a connection becomes one-piece;

- to the ceiling or walls and plastic round ventilation, and rectangular mounted with clamps. Since the weight of the structure is small, it is possible to use 1-2 clamps on the section of the ventilation channel.

Note! In order to perform the work more conveniently, it makes sense to assemble the entire structure on the floor, and only then raise it to the desired level.

Summarizing

It is impossible to call plastic an equivalent replacement for metal, after all, the fire resistance of the same galvanized steel cannot be replaced by it. But in private construction in rooms where air temperature is low such ventilation can quite be used. However, the growing demand for plastic air ducts speaks about the popularity of such material.

The video in this article shows an example of installed plastic ventilation.