Smoke-free ventilation: the main characteristics and

In this article we will talk about what constitutes a smoke-free ventilation system, according to what criteria it is calculated, and what are the features of its device.

Probably, there is not a single building object that would be completely protected from unauthorized ignition. In order to quickly and effectively remove smoke from the room in case of fire and limit the spread of combustion products, smoke exhaust ventilation system is used.

Application features

The standard anti-smoke ventilation system is used to supply air outside the object to the stairwells, elevator shafts and vestibule locks to prevent the spread of combustion products through these rooms (see also the article Ventilation for metal tile - purpose and installation).

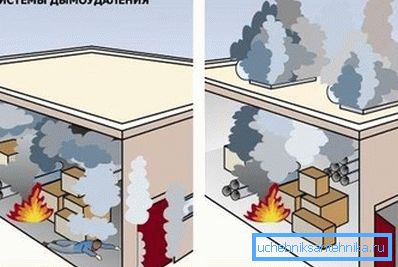

A properly designed intake system can effectively remove smoke and carbon monoxide both from rooms that are directly serviced in case of a fire, as well as from ancillary rooms, such as halls, corridors, etc. As a result, people can relatively safely leave the room where a fire was detected.

Devices responsible for smoke removal, in accordance with fire safety requirements, are mandatory for installation in such premises as:

- closed underground and aboveground parking;

- production workshops and storage facilities;

- rooms with permanent crowds of people;

- trading rooms and pavilions;

- theaters and cinemas;

- building atria above 28 m;

- passages;

- corridors over 15 m long that do not have natural light (according to SNiP 41-01-2003)

- waiting rooms at airports at train stations, etc.

Among the additional functions of smoke removal systems, we note the following:

- the creation of optimal working conditions for personnel responsible for the maintenance of special equipment operating in a continuous cycle;

- providing the conditions required for effective action by fire brigades when extinguishing fires and during rescue operations;

- ensuring the conditions necessary for the full functioning of a number of high-precision technological equipment.

Construction features

The design of anti-smoke ventilation is carried out taking into account the peculiarities of ventilation equipment designed to work with gases heated to high temperatures. In addition, the design and construction of such systems is carried out on the basis of the need to ensure the coordinated work of all the elements involved in the ventilation systems.

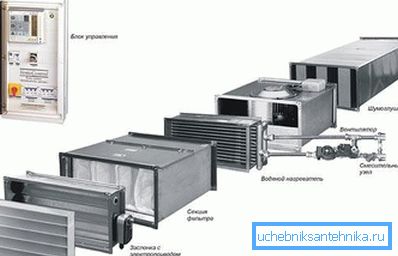

For the functioning of effective smoke removal schemes, such elements as:

- fans, specially designed and manufactured with the expectation of operating in particularly difficult operating conditions;

- ventilation ducts (manifolds, air ducts and mines) manufactured in accordance with the norms of fire resistance;

- open and closed fire dampers, including smoke and fire retardant modifications;

- smoke and gas fireproof doors and screens.

Important: Design of smoke exhaust ventilation systems in the corridors of residential and public buildings is performed separately from other systems used to protect the premises.

Calculation of smoke removal system

The instruction manual for smoke exhaust systems provides for the discharge of combustion products from smoke zones. In the standards of the times of the USSR, the area of such zones was estimated at 1500 m ?. Time passed and smoke removal according to SNiP 41-01-2003 provides for a smoke zone with an area of up to 3000 m ?.

Designing with your own hands systems for premises whose area exceeds 3,000 m ?, the smoke zone must be divided into several zones with an area of up to 3,000 m?, As stipulated in the relevant standards.

The calculation of the basic parameters of smoke-free ventilation of buildings is carried out in accordance with the requirements given in MDS 41-1.99 “Recommendations for smoke protection in fires”.

Important: In addition to these standards, the features of escape routes, their length, the simultaneous number of people who can take advantage of these ways during evacuation, etc. are taken into account.

The calculation of smoke-free ventilation has a single purpose, namely, the determination of the flow rate (quantity) of supply air, which is enough to smoke above and did not fall below the height of the upper zone of the corridor during the entire time required to evacuate people.

What you need to pay special attention to, conducting such calculations?

- We take into account the possibility of fire in rooms located not in one, but in each fire compartment of the building.

- We take into account the fact that, on average, the exhaust installation of smoke removal is characterized by a capacity of up to several thousand cubic meters per hour. At the same time, the flow rate in the fresh-air smoke protection system can reach tens of thousands of cubic meters per hour.

- We take into account the fact that the maximum air velocity in the smoke-free air ducts reaches 11 m / s, while the recommended speed ranges from 9 to 11 m / s.

Recommendations for equipment selection

- When choosing and purchasing smoke-proof equipment, savings are inappropriate. The fact is that the price of such equipment, even in the most expensive version, is an order of magnitude lower than the cost of equipment that can be evacuated during a fire.

It is unnecessary to remind that human life is priceless!

- Choosing fans to complete the system, we give preference to special modifications that are designed to work with gases heated to critical temperatures (up to + 600 ° С). As a rule, special roof anti-smoke or explosion-proof modifications are designed for operation in such conditions.

- The installation of anti-smoke fans is allowed only in rooms isolated from conventional fans.. If there is no isolated room for such needs, the equipment can be installed on the roof of a building.

- In systems of smoke-free ventilation, the use of ducts and ducts made of non-combustible materials corresponding to class "P" (fire resistance EI 30, EI 150).

- Lattices for the device of receiving openings for air intake from the outside should be located no closer than 5 meters from the place of the supposed discharge of combustion products from the ventilation systems.

Features of the organization of the management of smoke ventilation systems

In order for the smoke ventilation test to be successful, it is necessary to establish effective system management.

Modern smoke control ventilation system operates in two modes:

- in automatic mode, the ventilation is started after the fire alarm is triggered;

- in remote mode, ventilation is activated by pressing a button at the emergency exit from the floor.

Important: Smoke control systems should be designed in such a way that when the fans start up during a fire, the general ventilation and air-conditioning systems located and operating in the room where the fire occurred are automatically turned off.

Conclusion

So, we have reviewed general information related to the construction and operation of smoke-proof ventilation (see also the article Filtering system: the purpose of the device, the device, the study of samples).

You will find more useful information by watching the video in this article.