Ventilation ducts and air ducts in apartments and houses

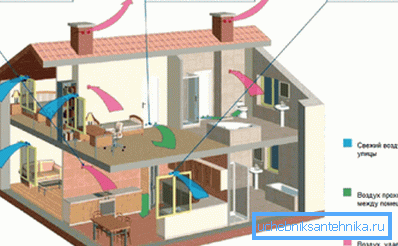

No construction of a dwelling house is complete without installing and connecting a natural or forced ventilation system. In multi-storey buildings, built-in air ducts made of brick or solid concrete are used most often for the removal of exhaust air from a residential area into the atmosphere, which are installed immediately during the construction of a house. When the ventilation stack is clogged, or if it is necessary to transfer the duct to another place, new metal or plastic rectangular ventilation ducts are used for external installation.

Rules for arranging ventilation ducts

When performing repair or installation work, you should be aware that the arrangement of a new, or re-equipment of the existing ventilation system with your own hands must be performed in strict accordance with established building codes and regulations.

In order to make it easier for the reader to deal with this simple task, this article will provide a brief overview, which describes the main features of the arrangement of main ducts and ventilation ducts in private homes and apartments.

Varieties of ventilation ducts

According to their design features and the relative positioning of the ventilation ducts relative to the bearing walls of the building, all air ducts can be divided into several types.

- Built-in ventilation ducts of rectangular or square cross-section, as a rule, are laid in the supporting walls of a building during its construction. In their manufacture, hand-laying of ventilation ducts from bricks, or the formation of special reinforced concrete blocks intended for the installation of such systems, is most often used.

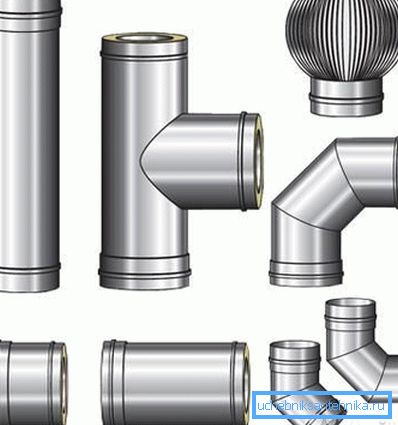

- False or suspended air ducts most often represent flat ducts for ventilation in the form of prefabricated box-shaped structures made of galvanized sheet steel.. Installation and connection of such systems is carried out after the completion of construction and finishing works, and in the case of redevelopment of the premises - after the completion of reconstruction, according to a specially developed technical project.

- External or in other words, additional ventilation ducts are a detached building structure that is installed on the outside of the building.. Such a system can be made of brick, solid concrete, as well as precast metal pipes made of galvanized or stainless steel.

Tip! Air ducts in private homes are recommended to be laid parallel to the furnace chimney, in close proximity to it. Such an arrangement, due to the upward flow of warm air can significantly increase cravings, and accordingly improve the efficiency of the ventilation system.

Material selection

At present, a large number of various materials are offered for the installation of air ducts, the price of which can vary significantly, but the right choice mainly depends on the specific conditions of construction and the specific use of a room.

- Built-in air ducts of monolithic concrete are of high strength and durability, easy to maintain, and in addition, with a uniform monolithic fill, they have little resistance to the movement of the air flow.

- Solid brick has similar operational properties, however, in most cases, the brickwork of the ventilation ducts can create turbulent turbulence, which significantly reduces cravings, so it is recommended to use it when installing ventilation systems with forced air circulation.

- Metal and plastic channels for ventilation are free from this drawback, but they are less durable, therefore, they need to be protected from external mechanical impact. In addition, all metal products (except stainless steel) are subject to atmospheric corrosion, and therefore need additional protection from moisture resulting from the formation of condensate.

- For installation inside a brick or concrete wall, built-in asbestos-cement ducts are also used. From the point of view of aerodynamics and performance, this material is most suitable for the installation of built-in ventilation systems in the process of building a brick or solid building.

- For installation of a ventilation system in a confined space, such as behind suspended ceilings or behind wall panels made of plasterboard, flat ventilation ducts of small thickness, made of plastic or metal, are well suited.

Tip! When self-assembly free-flow ventilation with natural air circulation, it is recommended to use round plastic ventilation ducts, because, due to their shape and smooth inner surface, they create minimal resistance to air movement.

Independent manufacture of the duct

As mentioned above, it is best to use a round asbestos-cement pipe for the installation of an integrated duct, therefore, step-by-step instructions for installing such a ventilation duct in a brickwork wall will be presented below.

- Carrying brick wall and a half and a half brick lay out in the usual way to the level of the location of the vent.

- At the bottom of the asbestos-cement pipe, cut the front wall to the axial line, to a height of 120 mm so that a stepped window is formed at its end.

- On the upper plane of the brickwork, install the asbestos-cement pipe with the window cut out into the room, and temporarily fasten it to the building structures (columns, beams, ceiling) with a knitting wire.

- Continue the brickwork in the same way, placing the brick on the edge in front and behind the asbestos-cement pipe.

- Thus, you need to bring the upper end of the asbestos-cement pipe with the surrounding brick to a level that is not lower than the upper part of the ridge of the roof.

Tip! To connect a horizontal ventilation duct to a vertical riser on other floors, in the right place of the asbestos-cement pipe, it is necessary to cut a rectangular or square window with a width equal to its diameter and a height of at least 120 mm.

Regulatory technical requirements

When independently performing installation work, it is necessary to comply with generally accepted norms and rules that relate to the arrangement of ventilation systems, and the shape of the internal section and the dimensions of the ventilation channels must strictly comply with the requirements of regulatory documents.

- The exhaust vent in the room should be located as close as possible to the ceiling, and the distance from the top edge to the ceiling should be no more than 100 mm.

- If the outlet of the pipe on the roof is located no further than 1500 mm from the ridge of the roof, its height must be at least 500 mm higher than the ridge.

- To improve natural thrust, and to protect the vertical riser from precipitation, its outlet should be equipped with a special stainless steel deflector.

- Vertical risers with natural air circulation should have a cross-sectional area of at least 140-180 cm?, Which roughly corresponds to a pipe diameter of 120-150 mm.

- The cross-sectional area of vertical risers with forced air circulation should be at least 90-130 cm ?, which corresponds to a diameter of a circular pipe of 100-130 mm.

- All vertical and horizontal ventilation ducts that pass through staircases, attics, or other unheated premises should have thermal insulation made of expanded polystyrene sheet or mineral wool, with a minimum thickness of 50 mm.

- To ensure normal thrust, in systems with natural or forced air circulation, all connections must be completely tight and free from visible signs of damage.

Conclusion

Regardless of the selected material and manufacturing technology, all air ducts and ventilation ducts according to SNiP 2.04.05-91 "Heating, ventilation and air conditioning" must fully comply with the technical characteristics specified in this regulatory document.

To get more detailed information on this issue, you can watch the video in this article or read the relevant regulatory and technical documentation on our website.