Ventilation flap: purpose, design features, operation

Damper valves for ventilation, or throttle valves, are designed to regulate and distribute the air flow in the ventilation ducts. This is one of the main ways to configure and control the system as a whole and its individual parts. We will tell about the device and features of throttle valves.

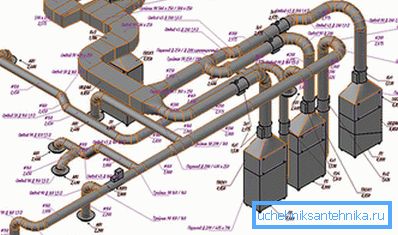

Throttle valves for ventilation ducts

Device

The air damper for ventilation is a frame that follows the shape of the channel section on which the blade or blade system is installed. The blades or paddle mounted on a rotary axis, the rotation of which provides a smooth adjustment of the position of the latter (also read the article Ventilation valve for plastic windows - the key to a healthy microclimate in the house).

The axis itself comes out at one end through the housing to the outside, where the control handle or the electric / pneumatic drive is located. The frame can be built into the channel as a shaped part or superimposed like a lattice. Connections can be flange, bandage and nipple.

Rotation of the axis ensures the mixing or opening of the channel, thus adjusting its throughput. In the extreme closed position, the blade is parallel to the plane of the section of the duct, in the extreme open - almost perpendicular.

Note! To rotate the axis more than 90 degrees, there is no point, as in this case, while maintaining the direction of rotation, the result will start to change to the opposite.

In the case of a system of blades, when the channel is blocked not by one blade, but by a design like a blind, the turning axis is not one, but as many as the blades. All these axes are also brought out at one end, where they are joined by a common pitch, by acting on which all the blades can be turned at the same angle.

Species

Valves are classified according to several parameters: purpose, form, type of control drive and main functions.

By appointment, all valves can be divided into the following groups:

- Air valves. Designed to adjust the movement of air masses without admixtures of flammable gases, aerosol suspended solids and smoke at temperatures up to 80 degrees. The maximum pressure in the channel is 1500 Pa. Used in ventilation systems of warehouses, vegetable stores and other household objects;

- Fireproof. There are two types - fire-retardant and smoke, while the former are usually normally open, the latter are normally closed. They protect the openings in enclosing structures from flame penetration, and also remove combustion gases from the premises;

- Explosion proof. Can be attributed to a variety of fire-fighting devices, but their main difference is work in explosive environments. The design is made so that the occurrence of a spark during its operation is excluded;

- Unified. The most common type of damper is used in the ventilation and air conditioning systems of civil and household objects, as well as in air heating systems.

In form, these devices repeat the contours of the channel section, and therefore there are three main types:

- round,

- rectangular,

- square.

Can also be embedded and overhead.

By the nature of the drive there are such varieties:

- Mechanical with a manual drive (marking - "P"). The rotary axis is equipped with a lever or a profile tip for gripping with a wrench. Often the lever is made in the form of a handle with a protractor, which shows the angle of rotation of the blade;

- Motorized ventilation flaps (labeled "E"). The control mechanic is driven by a servo mounted on the device body. Used in automatic systems and in channels of large cross section;

- Valves with pneumatic drive (marking - "P"). Differ from electric drive design.

In addition, devices are divided into different functional groups:

- check valves;

- emergency devices;

- normally open;

- normally closed;

- spring loaded, etc.

Control can be carried out by means of automation, a signal through a centralized remote control or manually.

Note! The price of each particular product is highly dependent on its purpose, size, type of drive and manufacturer. The cheapest species can cost from a few hundred rubles.

Features of regulation and adjustment

The main task of setting up and debugging ventilation systems is to ensure that the air flow parameters set by the project are set at all sites of the network.

It’s quite difficult to do this with your own hands without a set of basic knowledge, but if you do decide, our abstract instructions will help you:

- The total pressure and fan performance must be adapted to the design data. This is done by adjusting the frequency of its rotation;

- Next, with the help of adjusting devices configure the branches that are closer to the fan. The performance of these branches must match the design. By smoothly closing the dampers, the desired flow resistance is achieved;

- Excess air is transferred to those parts of the chain where there is a low productivity with respect to calculations. In those places where there are no adjustment devices, steel diaphragms can be installed to create a constant resistance;

- When the air flow rates in the head section of the circuit, as well as in the inlet and exhaust devices are brought to design values with an error of no more than 10%, the regulation can be considered successfully completed.

Note! Attention should be paid to increasing the power consumption of the fan motors with increasing their performance.

Conclusion

Ventilation valves and dampers allow you to configure the system and adjust its parameters in real time. Automatic mode and manual control of damper actuators are possible, which allows you to create sophisticated intelligent solutions for climate systems.

The video in this article clearly illustrates everything said.