Ventilation of industrial premises: tasks, types and

The creation of comfortable conditions at the workplace not only contributes to an increase in labor productivity, but is also a mandatory requirement of sanitary authorities. Therefore, ventilation systems for industrial premises are as important as normal lighting and central heating networks.

Their installation, in view of complexity, cannot be done by hand, however, an understanding of the principles of development, design and operation is unlikely to be superfluous.

The device of ventilation of industrial complexes

Tasks

Ventilation and air conditioning of industrial premises is carried out with the help of complex engineering systems, which, in addition to air ducts, include a lot of additional equipment: fans, filters, recuperators, heaters, coolers and so on.

Regardless of the type of production, the area of workshops and the level of air pollution, the ventilation system should perform the following tasks:

- provide workers with clean and fresh air;

- remove dust and odors from the room;

- filter harmful impurities that may be formed during certain technological operations.

For air exchange in industrial workshops, natural and mechanical ventilation, designed according to SNiP 41.01-2003, is used.

In addition to a comfortable air environment, the design of ventilation of industrial premises should pursue the goal of creating a temperature acceptable for operation. It is also provided for by the regulatory documents governing the sanitary condition of workshops in factories and mills.

Note! In the manufacture of certain types of products (for example, drugs or products of oil refining) substances hazardous to human health may be released. In this case, the ventilation system must ensure their quick and effective removal.

Design Principles

The calculation of the ventilation of the production premises should be carried out only by highly qualified engineers. It is necessary to take into account the nature of production, the area of the premises, the number of workers, climatic conditions and many other parameters.

However, each industrial ventilation system is built based on the principles listed below:

- Any ventilation system consists of exhaust and intake devices, air ducts and equipment that creates a comfortable indoor microclimate (air heaters, air conditioners, humidity stabilizers, and so on).

- A mandatory component of the ventilation of industrial premises is equipment that removes dust, aerosols and gases from the air, which are the result of the work of process equipment.

- Some industries (pharmaceuticals, high-precision electronics) require special environmental conditions. In this case, additional components are included in the ventilation system (for example, special filters or powerful air conditioners).

- The instruction manual for certain types of equipment provides that sections of workshops where hazardous fumes may appear should be equipped with special extractors-traps separated from the general shop network.

- Part of any air exchange system are devices that perform sanitary and hygienic control of ventilation systems of industrial premises. Depending on the readings of those or other sensors, additional equipment is connected that cleans the air or removes harmful impurities.

- When designing industrial ventilation networks, such a parameter as the price of their operation is taken into account. It is desirable that the hot air leaving the room is used in heat exchangers, and cold air is used to cool machines and other equipment.

Species

Depending on the tasks performed, industrial ventilation is divided into the following types:

- General exchange - provides the general replacement of air in rooms. An example is a conventional axial fan inserted into a window or wall vent. The power of the equipment is selected on the basis of the section and length of the duct.

- Individual (local) - cleans the air directly at the workplace. It is an extract that removes harmful impurities, dust, smoke and other substances that can cause harm to human health.

- Emergency - used for emergency cleaning of air from smoke, gas or other dangerous impurities. Requirements for ventilation of industrial premises used only in emergency cases differ from general standards, and will not be considered here.

In addition, according to the method of organizing the air flow industrial ventilation are:

- natural;

- mechanical.

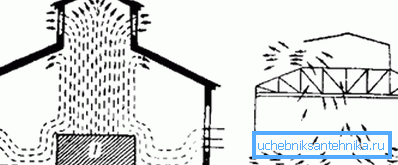

With a natural ventilation scheme, the influx and removal of air masses is due to the burden arising from the difference in temperature and pressure outside and inside the production room.

The effectiveness of such ventilation is influenced by:

- the temperature difference between the outside and inside the shop;

- the difference in atmospheric pressure in the area of the floor of the production room and the outlet of the exhaust channel;

- the speed of movement of air masses on the street.

The advantages of the natural ventilation system include efficiency, environmental friendliness and noiselessness. However, under certain weather conditions, its effectiveness drops sharply.

Mechanical ventilation is free from this drawback. In addition, it can move the air flow to any distance along the ducts of any section and configuration. In addition, in this case it is possible to install equipment that performs heating of the air, its cooling, dehumidification, humidification, filtration, and so on.

The most commonly used combination of natural and mechanical ventilation systems.

Regulations

The ventilation norms of industrial premises are fixed by SNiP 2.04.05-91 and 41-01-2003. According to these documents, the ventilation system should be installed in all industrial premises without exception, regardless of their functional purpose, area and number of people working in them.

The power of the equipment should be such as to quickly clean the air in the room in case of smoke or release of hazardous substances.

In addition, the design should take into account the following parameters:

- room functionality;

- square;

- climatic conditions;

- the presence and amount of pollutants;

- air humidity;

- temperature inside the workshop;

- fire safety and so on.

Note! The main parameter that must be considered is the rate of providing each employee with fresh air.

It is equal to 30 cu. meters per hour when the area of the room is equal to or less than 40 square meters. meters. In large industrial complexes, the standard increases proportionally.

Calculating the technical characteristics of the ventilation system, you should also pay attention to the following nuances:

- The noise emitted by the ventilation system should not stand out against the background of the sounds emitted by machine tools and technological equipment, otherwise it will be uncomfortable to be in the workshop.

- The air exchange network should not lead to additional air pollution in the production area. This often occurs when a long-mounted system has not been periodically cleaned of dust and other impurities that have accumulated there.

Installation of industrial ventilation

Selection of the optimal scheme

The modern market of engineering systems offers a huge selection of various ventilation systems, which make it possible to create the most comfortable conditions at the workplace. A wide range of devices that differ in both cost and functionality, is able to satisfy the needs of even the most fastidious customer.

When designing industrial ventilation, it is necessary to take care of acquiring and installing not only supply equipment that supplies clean air inside factory workshops, but also exhaust systems that remove air polluted from smoke, dust, harmful substances and, sometimes, pathogens from workplaces.

The choice of a particular type of equipment is made individually, taking into account the features inherent in a particular industrial facility.

The finished ventilation system should be:

- economical;

- effective;

- reliable;

- fast-paying.

Clean and cool air in the workshop not only has a beneficial effect on the performance and mood of employees, but also extends the life of the process equipment and tools used.

It is also economically feasible when developing a project to immediately provide for the inclusion of a device for creating a comfortable microclimate in the composition of the ventilation network, regardless of external conditions.

Tip! To control the operating parameters of the ventilation system, it is recommended to use automatic computerized systems that change certain parameters taking into account the data received from external sensors. So maximum efficiency and profitability of work is achieved.

Installation of equipment

When installing industrial ventilation systems, it is necessary to take into account the many nuances and features that affect both the efficiency of its operation and the durability of the structure. Therefore, only highly qualified specialists with relevant knowledge and experience should install individual elements of the air exchange network.

It is also important to choose the right places for the installation of electrical equipment: heat exchangers, fan installations, filtration systems, and so on.

In the future, from this room is distributing ducts.

Installation of air ducts

Ventilation ducts in industrial premises are usually attached to the ceiling. After that, they can be masked by hanging decorative panels. In commercial premises, it is advisable to use air ducts made of plastic or copper, which have a more attractive appearance.

In modern construction uses two main types of air channels:

- Hard. Manufactured from multi-layered aluminum, galvanized and fiberglass. Of these, almost the entire ventilation system is mounted. For arranging turns, contours, branches, special shaped parts are used. If it is intended to transport air containing aggressive impurities, it is necessary to use air ducts with increased wall thickness.

- Flexible. Their main purpose is to connect individual sections and suction openings with main ducts. Often, flexible aluminum hoses are used to install local ventilation that cleans the air near each workplace.

The order of installation of ventilation ducts in the premises for production purposes is as follows:

- First of all, you should calculate the wall thickness and cross section of the air channel. Then, on the basis of these data, the weight of each element of the ventilation system is calculated. In some cases it is not possible to install square channels due to lack of space. If you are faced with this situation, it is recommended to opt for rectangular ducts.

- After that, at the place of installation it is necessary to designate the fastening points of the air ducts. This allows you to count the number of brackets and other necessary hardware. Remember that the mounting brackets installed should exclude fluctuations in the length of the network sections during the passage of air through them. It is better to provide an excessive number of fasteners that can withstand the weight of the channels in case of increased load.

- After fixing the main channels, installation of individual nozzles and suction devices is performed. In this case, the use of flexible hoses of the desired section is recommended.

Conclusion

Design and installation of an industrial ventilation system is a very complex and demanding process. The finished engineering network must fully comply with strict rules laid down by applicable building codes and regulations.

On this depends not only the efficiency of its functioning, but also the health, and perhaps the life of the workers. You can learn more about this question from the video in this article.