Ventilation units: technical characteristics and

Any building needs high-quality ventilation. In residential high-rise buildings and industrial complexes, special ventilation units help to implement it. They are lined up in whole systems, uniting all residential and utility rooms. Next, we analyze the wonders of engineering in more detail.

General provisions

First of all, let's pay a little attention to the ventilation process itself, or rather the question: why is it needed? Here you can highlight the two most important factors:

| Factor | Significance |

| Person | Indoors accumulates carbon dioxide, excessive moisture, various emissions used during the construction of materials, furniture structures and other household accessories. If in small doses, all these impurities do not threaten human health, then without sufficient air circulation such a “cocktail” can lead to the emergence of various ailments. Especially the situation is aggravated in the presence of heating systems that distribute the products of combustion of energy carriers, which represent the greatest danger. |

| Building | Of all of the above, which threatens a person, the building is most likely to be damaged by an excessive amount of moisture. The accumulated moisture spreads the fungus, mold, causes the processes of decay and corrosion. Intensive movement of air masses copes with the drying of the room, greatly extending its operational life. |

Thus, we see that the implementation of proper ventilation is incredibly important both for the residents and for the building itself. And if in private houses one pipe is mainly used to perform this task, then in large buildings with many rooms it will be more rational to create a ventilation system at once in the walls using the considered blocks.

Description and application

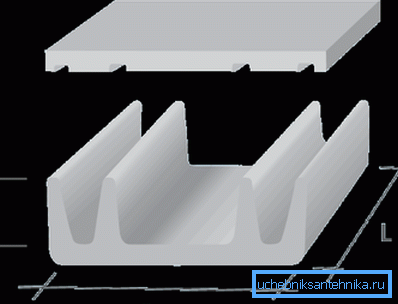

The ventilation unit is a self-supporting element of the building structure, which has various types of ventilation ducts. Fastened predominantly to the bearing walls or floor slabs using a welding machine and cement mortar. The combination of many such sections and forms a single effective system for the exchange of air masses (see also the article “Roof ventilation” is an uncomplicated but important step in home improvement).

Structural differences

The following types of ventilation units are used:

- Monolithic. They are created from one main component, including a collecting channel and inclined satellite channels, and two additional components, equipped only with vertical channels. Additionally, they are equipped with special embedded elements, with the help of which the fixing of blocks to bearing surfaces is realized. Such models are characterized by high reliability and efficiency due to absolute sealing.

- Prefabricated. They are assembled at the installation site by connecting two components with the help of a welding machine. Thus, transportation and installation of such products are much easier. Their price is also predominantly lower. But it should be noted the drop in performance indicators due to the appearance of docking seams.

Raw materials options

The composition of the raw materials used in the manufacture of ventilation units may differ, which affects their functionality.

Let's look at the most common:

- Reinforced concrete. Reinforced concrete is characterized by increased strength and reliability due to the presence of a metal "skeleton". But it also gives it a very large weight, which in turn requires a reinforced foundation and adds additional difficulties in the installation of their own hands.

- Gypsum concrete. The presence of gypsum in the composition can significantly ease the mass of the whole structure due to some loss in strength. In general, the ventilation system made of such material comes out more economical, since it is not necessary to reinforce the base, and installation work in some cases can do without the use of expensive lifts.

- Claydite. Adding claydite to concrete can significantly reduce the thermal conductivity of the finished product. In addition, such products have a very high fire resistance, which is never superfluous in the construction of both residential and industrial facilities.

Tip: in buildings with a weak heating system, it is recommended to use keramsit concrete blocks when creating ventilation. Due to the thermal insulation properties of this material, the outgoing air masses will cool more slowly, guaranteeing a high flow force.

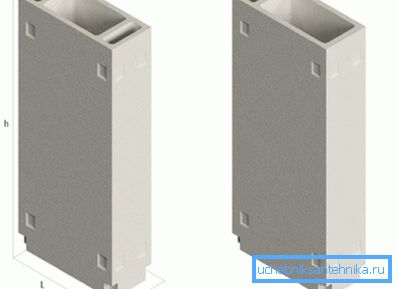

Dimensions

The linear dimensions of the ventilation units are presented in the following table:

| Mark | Length (h), m | Width (l), m | Height (b), m | Volume m3 |

| BV-28 | 2.78 | 0.8 | 0.4 | 0.39 |

| BV-29 | 2.83 | 0.8 | 0.4 | 0.4 |

| BV-30 | 2.98 | 0.8 | 0.4 | 0.42 |

| BV-31 | 3.13 | 0.8 | 0.4 | 0.44 |

| BV-33 | 3.28 | 0.8 | 0.4 | 0.46 |

| BV-28.93.2 | 2.78 | 0.93 | 0.5 | 0.43 |

| BV-30.93 | 2.98 | 0.93 | 0.5 | 0.52 |

| BV-31.93 | 3.13 | 0.93 | 0.5 | 0.55 |

| BV-33.93 | 3.28 | 0.93 | 0.5 | 0.57 |

| SVB-1.2 | 2.78 | 0.88 | 0.3 | 0.35 |

| SVB-1.4 | 3.58 | 0.88 | 0.3 | 0.45 |

Assembly work

Tip: even if you do the installation of the ventilation units with your own hands, it is still recommended to use the services of a professional architect. He will be able to calculate the optimal design taking into account all the features of the building, which ultimately will save on materials and ensures high efficiency of the future ventilation system.

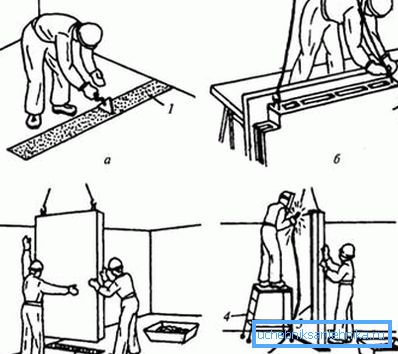

To perform all the necessary work, two installers and one scaffold are required.

The instruction of their activities is as follows:

- The first step is to remove all possible debris from the bottom support, on which the installation will be carried out, in order to avoid distortions and increase adhesion performance.

- Then the surface is wetted and closed with a special frame-plug, which will avoid the penetration of cement mortar into the ventilation ducts.

- Mixed solution of cement and sand in the ratio of 1: 3.

Tip: It is recommended to use the factory cement-sand mixture, as it has a higher quality and accurate proportions.

- The resulting homogeneous mixture is superimposed on the template with a spade.

- The solution is stretched with a trowel at the end of the underlying product, after which the frame is removed.

- Now the services of a scaffold are required, which, inspecting the block, slings it off and allows it to be lifted.

- The installers take the ventilation unit to the installation area and make sure that all the holes coincide with the previous section, and the end parts are lowered strictly onto the cement bed.

- The vertical level is controlled by the vertical structure. This is a very important point, since the assumption of the smallest error can lead to its geometric progression on the blocks installed in the future.

- With the help of crowbars made the necessary adjustments to the position of the product.

- Next is tacking embedded parts of the welding machine to the wall partitions. The unit itself during such a process should be followed to avoid possible bias.

- The final stage is processing and sealing the horizontal seam with trowels, after which you can proceed to the next section.

Conclusion

High-quality, properly functioning ventilation is needed in every building. Without it, not only the health of people, but also the integrity of the building itself is endangered. Concrete ventilation units allow you to implement a durable and reliable system (read also the article “Passport of the ventilation system: the objectives of the receipt, the form and regulatory requirements for the system).

Today's manufacturer offers many variations of such products, differing in structural features, technical parameters and materials of manufacture. Above are the most common of them, as well as with features of the installation work.

The video in this article will provide you with additional information that is directly related to the materials presented.

Ventilation units - the best way to create ventilation in high-rise buildings and industrial complexes.