Ventilation with heat recovery: device, performance

What kind of device is a heat recuperator? How does energy-saving supply and exhaust ventilation work - ventilation with heat recovery plate or rotary units? How quickly will the recuperator purchase pay off? Can I make it with my own hands? Let's try to answer these questions.

What it is

Principle of operation

Speaking somewhat simplified, we have a conventional heat exchanger. It takes away some of the heat from the exhaust air that is removed through the exhaust ventilation system, and transfers this heat to the air flow in the intake duct. The goal is pretty obvious: house ventilation with heat recovery is designed to reduce the cost of heating homes.

Specify: in the summer heat recovery will reduce the cost of air conditioning. The heat exchanger is able to work in both directions: heat is transferred both from the exhaust duct to the intake duct and from the intake duct.

Problems

There are not so many potential problems associated with recovery.

Some of them are usually decided by the manufacturer, some are a headache for a potential buyer.

- Condensate. When passing the exhaust air through a relatively cold heat exchanger on it will inevitably condense moisture. Worse: at temperatures significantly below zero, the fins will frost up, catastrophically reducing the efficiency of the device.

- Energy efficiency. Virtually all heat recovery ventilation units are volatile. Obviously, their purchase will be meaningful only if they save significantly more energy than they spend.

- Payback period. If it exceeds 10-12 years, the recuperator becomes a dubious acquisition: during this time, as a rule, some parts of the structure (at least fans) will require replacement, which will increase overhead costs. The payback period of 20 years clearly indicates that the purchase is meaningless.

Execution options

How can recuperation ventilation system work? We list the basic schemes with their brief description.

Lamellar

Exhaust and intake channels pass through a common body, divided by a partition. The partition is permeated with plates of the heat exchanger - most often aluminum, less often - copper.

Reference: copper has twice the thermal conductivity, but it is much more expensive than aluminum.

Heat is transferred between the channels due to the thermal conductivity of the plates. It is obvious that in this case the problem of condensate will rise in full growth. How is she solved?

The recuperator is supplied with an unpretentious icing sensor (usually thermal), at the signal from which the relay opens the valve - bypass. Cold air from the street begins to flow around the heat exchanger; warm flow in the exhaust channel quickly melts the ice on the surface of the plates.

This class of devices belongs to the lowest price category; The retail price is almost linearly dependent on the size of the duct. We give the prices of the Ukrainian online store Rosette at the time of this writing:

| Model | Size of ventilation | Price |

| Vents PR 160 | Diameter 160 mm | 20880 r. |

| PR 400x200 | 400x200 mm | 25060 r. |

| PR 600x300 | 600x300 mm | 47600 r. |

| PR 1000x500 | 1000x500 mm | 98300 r. |

With heat pipes

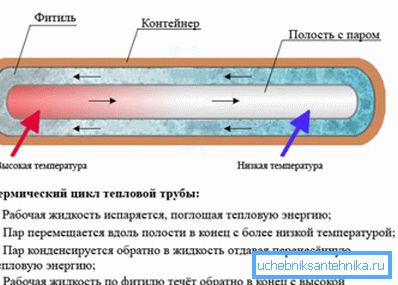

The device of the heat exchanger is completely identical to that described above. The only difference is that the heat exchanger plates do not penetrate the septum between the channels; they are pressed onto the heat pipes passing through the partition.

Reference: heat pipe is a non-volatile device for heat transfer. Freon evaporates at the warmer end of the sealed copper tube and condenses in the cooler end; condensate is returned through the capillary wick.

Due to the heat pipes, parts of the heat exchanger can be separated for some distance.

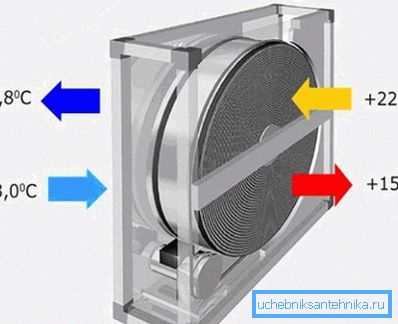

Rotary

At the boundary between the intake and exhaust ducts, the rotor with lamellar fins slowly rotates. The plates heated in one of the channels give off heat in the second channel.

What does the rotor heat recovery in ventilation systems in practical terms?

- The efficiency increase from 40-50%, typical for plate devices, to 70-75%.

- Solving the condensate problem. Moisture deposited on the rotor plates in warm air completely evaporates when heat is transferred to the cold air flow. At the same time solves the problem of low humidity in winter.

Alas, the scheme has several drawbacks.

- The greater complexity of the design means reduced fault tolerance.

- For wet rooms rotor scheme is not suitable.

- The chambers of the heat exchanger are separated by a non-hermetic partition. If so - the smells from the exhaust channel can get into the intake.

Intermediate heat carrier

For heat transfer, a classic water heating system with a circulating pump and convectors is used. The complexity and rather low efficiency (usually not more than 50%) are justified only in cases where the supply and exhaust ducts due to the architectural features of the building are separated by a considerable distance.

Effectiveness study

How justified is air recovery? We will explain this by the example of a small study of a private house.

Given

- It is estimated that about 25–35% of the heat is carried away through winter ventilation. Take the average value - 30%.

- The floor of a house inhabited in winter is heated round the clock by a single inverter air conditioner with a nominal effective thermal capacity of 3.2 kW. The average real power consumption, judging by the meter readings, is about 500 watts.

To clarify: the place of action is Sevastopol with an average January temperature of + 3.5 degrees. It is clear that in colder regions, the energy consumption for heating will be much greater, and the very possibility of using an air heat pump will be questionable.

- When using a plate heat exchanger, the energy consumption for its operation will be limited by the consumption of electricity by a pair of channel fans with a total capacity of about 30 watts.

- Efficiency recovery will take a very real 40%. The duration of the heating season, during which it will provide any effective savings - from November to March, 5 months.

Note! Efficiency will decrease when the delta of temperatures between the room and the street falls; however, to simplify calculations, we ignore this fact.

Payment

Let's calculate the average monthly savings that the simplest heat exchanger will provide, and its payback period at a cost of 20,000 rubles.

- Since only 30% of the heat is carried away by ventilation, it would be logical to multiply by 0.3 the average electricity consumption of air conditioning. We get the amount of energy that flies uselessly into the ventilation channel. 500 * 0.3 = 150 watts.

- The efficiency of recovery, we agreed to take equal to 40%. 150 * 0.4 = 60 watts.

- Forced ventilation will eat 30 of them. In the useful balance - 60-30 = 30 watts. This is the constant electrical power that the heat exchanger will save in the heating season.

- In a month we will save 30 watts / hour * 24 hours * 30 days = 21600 watts. With the current cost of a kilowatt-hour in the Crimea at 1.64 rubles, the monthly savings in the heating season will be 21.6 * 1.64 = 35.424 rubles.

- For five months of the heating season, 35 * 5 = 175 rubles will be saved. Since in summer, with a minimum temperature delta with the street, the recuperator practically will not work, it is precisely this amount that can be safely considered as the savings for the whole year.

- The payback period (note, without taking into account the cost of installation) will thus be 20,000/175 = 114 years (assuming unchanged electricity tariffs, which is unrealistic).

Conclusions, it seems, are obvious.

crazy hands

How to reduce the cost of the purchase? Can a ventilation system with heat recovery with the help of scrap materials be created?

The instruction is quite simple.

- Cut aluminum tubes with a diameter of 10 mm.

- We cut two plates from sheet aluminum with a thickness of 4 mm and drill holes in them for the outer diameter of the tubes.

- We assemble the heat exchanger on silicone sealant and place it into an assembly from a ventilation pipe and three tees.

- Install channel fans in such a way as to organize the air flow in the directions indicated in the scheme.

Conclusion

We hope that acquaintance with the concept of heat saving through recuperation and the above calculations will help the reader.

As always, he will find additional subject materials in the video in this article. Successes!