What are heat exchangers for ventilation: the differences

Replacing the air in the room when the temperature difference inside and outside is always threatened with discomfort, and sometimes even unacceptable. Therefore, the manufacture of heat exchangers for ventilation in some cases is essential for creating civilized conditions.

Such constructions can work from electricity, from water and from the natural heat of the top layer of soil, but their cost, which is quite natural, will differ greatly from each other. We now pay attention to cheaper options and completeness of information will show you the video in this article.

Heat exchangers

Note. Electric, ground or water heat exchanger for ventilation is designed to stabilize the temperature of the air drawn in. So, passing through a heated or cooled device, the air flow can be heated or cooled, depending on the temperature conditions of the unit.

Differences

- As we have said, there are three types of heat exchangers according to the method of maintaining their temperature:

- electric (converts electricity into heat or cold);

- water (uses the temperature of the liquid coolant in the heating system or air heater);

- groundwater (uses the natural temperature of the earth’s upper layer).

- In addition, underground units can also be different, that is, channel and channelless. Channel installations imply a system of pipes (ducts) buried beneath the ground through which the intake air passes.

- But for pipe-free installation, pipes are needed only for sucking in air from the surface and drawing it into the room - heat treatment takes place in a special niche, usually filled with gravel, but more on that below.

Note. There is one more type of heat exchanger - it is a recuperator, which in translation from Latin literally means receiving back or returning. This is a surface installation that uses the heat of the gases coming from the room. That is, the air drawn in contact with the ejected flow through the thin wall, thus maintaining a constant temperature.

Water systems

A two-, three- or four-row water heat exchanger for fresh air can be embedded in the heat supply system - this is exactly how our industry produces them (it is possible that there are other options somewhere). A larger number of rows helps to increase the area for contacting the intake air with the heat-transfer fluid (through the wall).

But the more pipes for air, the less space is left for the transmission of the liquid coolant, therefore, here you need to either significantly increase the size of the mixer, or find a middle ground.

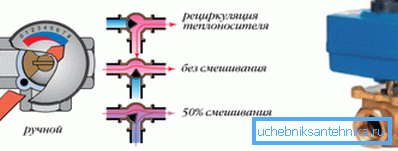

The main problem of heat exchangers of this type is the inability to regulate the temperature of the intake air - it is completely dependent on the heating of the heater, but there is a way out. In order to be able to regulate the temperature of the flow, install a three-way valve, which directs the heat-transfer fluid along a large or small circle.

And it can also generally stop its movement with sufficient heating of the large circle, as required by the instructions. That is, if the sensor indicates that the room has heated up sufficiently, the coolant is sent to a small circle, thus the circulation continues, although the heat transfer area is practically canceled.

Three-way cranes are:

- mechanical, where the coolant flow control is done manually;

- automatic, where the flux is directed by a servo driven by 220V (its price is, of course, much higher).

The last option allows you to set a certain temperature, and the heating adjustment will occur in automatic mode, thereby maintaining not only the water temperature, but also the temperature of the intake air that passes through the mixer.

Groundwater (underground) systems

Financially beneficial is the ground heat exchanger for ventilation, since you spend money solely on its installation and materials, and you get the thermal energy for free from the bowels of the earth.

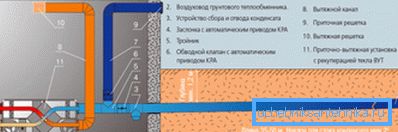

Most often for the installation of such a system, polyvinyl chloride (PVC) pipes with a diameter of 200-250 mm are used. They are designed for laying sewers - they are relatively cheap and they are very convenient to install thanks to the sockets and sealing bands. In addition, laying of sewage pipes on turns does not require any welding work or gluing - such differences are possible due to fittings (angles, tees, quadrangles and reductions).

When laying pipes underground, it is necessary to adhere to a certain depth, which depends on the level of soil freezing in the region. For example, if in your area the soil in winter time freezes to a depth of one meter, then it will be warm half a meter lower.

Therefore, the installation should be carried out at a depth of one and a half or two meters, where the temperature does not fall below 10? C. It is also necessary to observe a slope of approximately 2 cm / 1m running to allow the condensate to flow inside.

But if you want to install such a system for your own home, you can make it channelless. That is, instead of pipes buried under the ground, you will use a niche filled with rubble, which will serve as a place for heating the intake air.

To do this, again, you need to know the depth of soil freezing in your region, so that, stepping back from it 0.5-1m, dig a pit at 3.5-4m depth and somewhere 80 cm wide. The pit is filled with gravel (the larger the fraction, the better air exchange) is exactly 3.5-4 meters, and the rest is covered with soil.

A vertical pipe is installed for air intake, and another pipe at the outlet of the stone filter is used to feed the room. It is noteworthy that the repair of ventilation heat exchangers made of this type is practically not required. And if suddenly there is such a need, it is more associated with cleaning or replacing the suction pipe, which is not difficult.

Conclusion

As you can see, of all the listed types of heat exchange systems, it is easiest to build a ductless air duct with your own hands The advantage of it is that it filters the flow of air, but this is also its disadvantage, since the filter slows down the flow.