What is exhaust ventilation - features and types

Ventilation is one of the engineering life support systems responsible for the efficient circulation of air in any type of room. The absence of a properly organized ventilation system can lead to stagnation of air, changes in the humidity level at which the formation of mold, fungi, and unpleasant smell in the room is possible. Let's take a look at how exhaust ventilation works and how good it is.

Purpose of exhaust ventilation and its types

The main task of this system is to circulate the air flow in the premises. It is carried out by organizing the movement of air entering the room from the outside and its subsequent smooth removal.

Note! Air flow from the street is based on the principle of exhaust ventilation. Without this, in the room with a working hood, air will be rarefied.

Household ventilation systems

The system of exhaust ventilation of dwellings and, for example, office premises can be divided into:

- Customized, that is, serving one or more adjacent rooms. Usually for residential premises it is a kitchen and a bathroom, or the ventilation of a country private house. Where natural air exchange is impossible, the installation of exhaust ventilation with coercion is necessary. For this, a fan (centrifugal or axial) is built into the ventilation channel.

- The removal of air from the bathrooms usually takes place through small chimneys for ventilation, laid in the construction of ceilings or directly to the street through the outer wall.

- It is possible to combine extracts from several bathrooms into a common canal.

Note! The fan, as a rule, is easily connected with your hands in parallel with the light switch. Sometimes, an additional time relay is installed, prolonging the fan operation after turning off the lighting, for a while.

- The fans are equipped with a special valve that allows the air to move when the unit is turned on and locks the passage when it is turned off.

- In kitchens, to locate the removal of smoke and steam above the stove, an umbrella is installed that also carries a decorative load. The hood is equipped with a fan and a filter consisting of:

- Fat and dirt grids.

- Cartridge with substances that neutralize unpleasant odors. This is usually a sorbent, for example, activated carbon. This device should be replaced about 2-3 times a year as it gets dirty.

- Central. These are arranged, for example, in apartment buildings, where exhaust ventilation in the apartment is carried out through a system of separate channels that have access over the roof of the building. This is especially true of reinforced concrete precast high-rises, where the design of individual exhaust systems is difficult.

- Each apartment in the bathroom and the kitchen has an exit with a built-in ventilation grille to the vertical ventilation channel.

- All channels go to the roof where fans are installed above them.

- You can combine the vertical channels in one on top of the building and install one powerful fan.

- If there is a technical floor in the house-building, vertical ventilation channels are assembled into a common main air duct in this room. It can serve the engine for exhaust ventilation, installed in a superstructure above the engine room of an elevator shaft.

Interesting! A feature of the central ventilation of apartment buildings is the provision of sound insulation. So that the neighbors do not hear each other through the ventilation channels, special sound absorbers are installed in them.

- Combined exhaust systems are endowed with the advantages and disadvantages of central and individual ventilation.

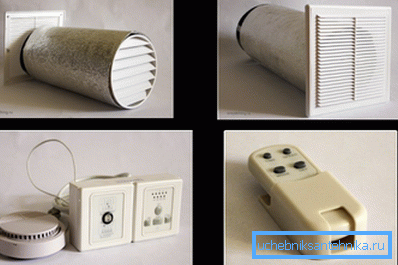

In addition to the fans, installation into the ventilation systems of an exhaust ventilation valve or a simple grille providing air exchange without coercion is practiced. The ventilation valve is an adjustable damper, with a fastening element, responsible for the intensity of air removal from the room.

All of the above devices are mounted directly at the entrance to the ventilation duct.

Attention! In rooms where wooden windows on metal-plastic have not yet changed, you can not worry about the natural flow of air even with the windows closed. When replacing windows with plastic, try to acquire designs with an integrated air valve.

Ventilation of industrial premises

Industrial exhaust ventilation in addition to creating a comfortable working environment performs several tasks, depending on the purpose of production:

- Removal of fumes in particularly hazardous areas.

- Ensuring sufficient traction in the boilers.

- Additional blowing hot parts, etc.

Ventilation systems in production are designed taking into account many factors:

- Purpose of the enterprise.

- Area of industrial premises.

- The number of people working in a particular room and their type of activity.

- The number and nature of equipment operating in workshops, etc.

Note! When calculating the ventilation, the climatic features of the region in which the production is located must be taken into account.

According to the principle of operation exhaust ventilation in production can be:

- Natural.

- Forced.

- Mixed type.

Natural ventilation in production, as in everyday life, is carried out with free air penetration from the outside and its removal through the ventilation ducts.

The thrust with this method of ventilation of rooms depends on the conventions of the surrounding atmosphere:

- Pressure.

- Temperature differences.

- Wind speeds

Utilization of air flows through the holes in the ventilation ducts. In the production premises, these openings are located at a height of 180 and 400 cm from the floor.

The forced system is equipped with special equipment - axial fans, which help to actively remove exhaust air from the room.

In the case of the use of forced-air forced ventilation circuit, the fan provides additional air supply in the required volume, increasing the efficiency of air exchange.

Fan power is selected based on the design calculations of the required air exchange.

Tip! When choosing a suitable unit it is not advisable to deviate from this value in a big way (with a margin), since the price of an industrial fan directly depends on its power. In addition, this would entail an unnecessary cost overrun in its further operation.

Ventilation system design

As well as the creation of any other engineering communications, the exhaust ventilation device is preceded by calculations and design.

This process is performed according to the technical specifications and consists in:

- Determining the ventilation power optimal for a room with a specific volume and purpose.

- Calculation of lengths and sections of air ducts.

- Completion of duct fittings and additional devices.

- Calculation and selection of equipment.

- The choice of consumables.

Determination of air exchange

The main technical instruction for the design of ventilation is a SNiP 41-01-2003, which regulates the normative rate of air exchange for various rooms, depending on their functional purpose. Also, this document provides for the following norms of hourly air consumption by one person, depending on the occupation:

Note! It is due to the rules and regulations that exist for air exchange systems, it is recommended to install exhaust ventilation with the help of specialized workers.

- For production premises:

- With natural ventilation - 30m3.

- Without natural ventilation - 60m3.

Standard multiplicity of air exchange - a value without a unit of measure, indicating the number of times a complete replacement of air in a particular room within one hour:

- For residential premises - air exchange rate is 1, but not less than 30 m3 / h per person.

- For bathrooms and kitchens - air exchange rate is 1.5, but not less than 60 m3 / h per person.

Knowing these values and parameters of the room, it is possible to calculate the design capacity of ventilation in two ways:

- The first with the use of air exchange rate according to the formula L = n * V, where:

- L is the calculated ventilation power.

- n - normative frequency of air exchange.

- V is the volume of the room, equal to the product of its area and height.

As a rule, the required rated power of the ventilation system falls into the range:

- 100-500 m3 / h for apartments.

- 1000-2500 m3 // h for private houses.

- 1000-15000 m3 / h for administrative, warehouse and industrial premises.

The composition of the ventilation system

Having received the design capacity of ventilation, you can begin to draw up the layout of its main elements.

The composition of a typical ventilation system includes:

- Exhaust ventilation hose - round air duct, or a box with a rectangular cross section, for air distribution in all rooms. Its length, configuration and cross-sectional area depend on the layout of the premises, as well as on the design features of a particular system and its purpose.

- The air intake grille is mounted directly at the entrance to the ventilation duct.

- Fan for guaranteed sufficient air exchange.

- Filter for air purification from mechanical and chemical impurities. Filters are used both in hazardous production (in garages, car services, etc.) and in everyday life. There are two types of filters:

- Replaceable for single use.

- Cleared. They can be dismantled, cleaned and put back in place.

We remind you that the design and installation of the ventilation system is better to provide in the hands of professionals.

Conclusion

Now you know the difference between natural exhaust ventilation and artificially created, equipped in rooms with high humidity. In this case, it is better to build this system before the end of the repair, so that it would be easier to hide the unsightly branching of the duct.

In the presented video in this article you will find additional information on this topic.