Why do we need and how are commissioning works of

If we talk about a more or less serious and responsible approach to the creation of ventilation systems at home, then without such a stage as commissioning of ventilation is indispensable. Because it is at this stage that errors or deviations from the existing rules and regulations are detected.

Contractor Relationships

If the company that will do the ventilation in your house or building refuses to test the system as it should be in the future, then it is worth it. Indeed, during such work, installers and designers are somehow improved by identifying errors — each time there are fewer and fewer blunders.

In addition, the “testing” of the system also speaks about how professionally and harmoniously the relationships of installers, designers and managers within the hired organization are built. After all, after testing, the installers are discharged and if something is wrong, then those who planned the ventilation immediately connect to the problem.

In a sense, the presence in the contract of a clause to carry out such work is a signal that you are dealing with a really serious organization whose leaders understand the importance of this stage.

Unfortunately, the situation when commissioning is not performed at all and is not provided for in the contract is not uncommon. Be sure to pay attention to the presence of this item - its absence most often indicates that the staff of a particular company simply does not have specialists with a clear understanding of the laws of aerodynamics.

Be sure to check with what tools, instruments will be commissioned.

A sign of professionalism is the use of, for example, such tools:

- anemometer and thermometer;

- micromanometer;

- differential type manometer for ventilation ranges;

- barometer and tachometer;

- pneumometric tubes, sound level meter, etc.

That is, simply put, the commissioning of ventilation is not a primitive action, like turning on the start button on the subject “it works — it doesn't work”, but, in fact, the whole process.

Please note: It is highly desirable that commissioning should be carried out by the organization that carries out the installation of the system and its design. If for this stage to look for another contractor, then the risk is high to delay the start-up of ventilation. Very often, due to the fact that there is no normal contact between the two firms, quick contact (and sometimes mutual understanding) can delay the time to correct defects, supply the necessary parts, etc.

Of course, if we are talking about a fairly simple ventilation system - for a single-story private house, for example, this stage may not be so important. However, with the implementation of more or less serious projects - full testing is really necessary.

And besides, later, in case of inefficient ventilation, it will be much harder to carry out the tests, since communications can be closed by facing, the room will be occupied by people, etc.

Let's look at the minimum actions that installers should do at their own stage.

Commissioning step by step

It should be noted that as illustrative examples we will analyze the actions that are usually carried out for fairly large-scale systems.

But in principle, the instructions provided below can be taken as a basis for testing less serious ventilation, since at each stage we will explain the main essence of the actions, that is, for what it is generally needed and what it affects.

Let's start with the simplest.

Check fan operation

Ideally, of course, to check the fans before they are embedded in ducts - such a preliminary check is usually done on a special stand.

In general, during such work, approximately such defects and deviations are revealed:

- The performance of the start buttons and those that regulate the power of discharge or suction of air;

- The width of the gap between the wheel device and the suction cone. This indicator should not be more than 1% of the total diameter of the wheel. As practice shows, with a larger gap, the fan is simply not capable of delivering the declared power of pressure.

- The correctness of the direction of the wheel. This factor affects not only the evenness of the air flow in a given direction, but also the performance of the device itself. If the wheel is installed and rotates in an uneven position, then there is a high risk of vibration and, accordingly, loosening of fasteners, nuts, etc.

Note! Incorrectly set position also affects the noise level of the instrument. The more accurate the installation, the smaller the number of decibels will penetrate the room.

By the way, if we are to be completely objective, then one detail can be noted - imported fans make much more noise than domestic products. Not for nothing, in the end, the price of devices is different.

So - if an imported fan started to buzz in your system, then 90% that these are consequences of improper installation, and not the “fault” of the device.

Now let's take a look at how to check the operation of the mounted ducts without the presence of test instruments.

Traction test "popular" ways

These are, in fact, the simplest actions that can be done to approximate the effectiveness of a system made.

First, you need to simulate a situation close to reality - that is, to create the conditions of the situation in which you plan to operate the hood. For example, you can close all the doors that are supposed to be closed — or, on the contrary, open them.

Points of air flow need to be checked by hand - just bring them to the hole - if the air pressure is really noticeable, then in principle the "inflow" functions normally.

As for the exhaust directly, you need to check the draft not with paper, as many advise, but with smoke. The fact is that the paper can be drawn into the canal even due to the pressure difference in the room and in the air ducts.

But if, for example, a person lit a cigarette and the smoke does not spread around the room, but is pulled into a ventilation grate, then this is the first sign that everything has been done normally.

But, of course, for greater certainty, instrumental control will not interfere.

Consider what is the point, and what is the instruction action.

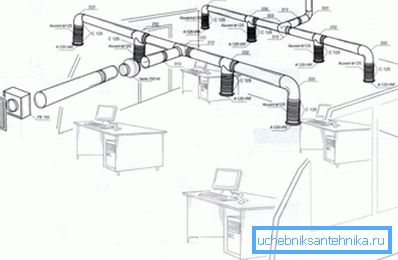

Verification of system performance using instruments

It turns out that we need to make a simplified adjustment, after which we will be able to determine the air flow.

This is done approximately according to this scheme:

- The site of communications without bends is selected.. Its length should ideally be at least 6 meters.

- At the point of nearest resistance, a hole is made to insert the pneumometric tube.. The hole can then be closed in an elementary way - with a cork or clamp.

Advice: if similar commissioning works on ventilation are carried out at an industrial facility, then it is possible not to engage in sealing of such openings at all. Because their presence in fact does not affect the performance of a system with a large diameter duct at all.

- A pneumometric tube is inserted into the hole and as it were led from wall to wall. At the same time, changes in dynamic pressure are observed near each of the walls — if the indicators are approximately the same, then this section is suitable for further tests and measurements.

- Next is determined by the mobility, air velocity - this can be done using an anemometer. If the data obtained coincides with those laid down in the project documentation, then in general, we can assume that everything has been done correctly.

In the case when the performance deviates too much from the norm - you need to move on to more complex operations. Typically, the full and dynamic pressure of the flow is measured before the fan starts and after it is turned on - thus, air flow figures are obtained. If the difference between them is 5% or slightly less, then on the whole it is very normal.

If the indicator is more than 5%, then it is worth trying to find sections of the highway that are clogged, or inside have any obstacle to the normal passage of air flow. In addition, you need to check the entire line for compliance with the scheme - perhaps somewhere the diameters of the elements do not match or there is a shortage of any device.

If everything is clean, normal, then you can simply try to increase the power of the fan speed if the technical conditions and standards of documentation allow it.

And consider another stage of testing such a highway.

Leak test

This work is not always performed and is often considered optional, additional. Whether or not to check a particular system depends on its features and your tasks. But in general, this is usually not provided for and if done, then the cost of commissioning works on ventilation increases accordingly.

How such a check is carried out is easiest - discussed in the table below.

| Act: | The essence of the action: |

| 1. Close all air grids. | This is then necessary in order to create the most suitable test environment. Agree, with open holes it will be almost impossible to determine the point of loss. |

| 2. Turn on the fan. | The device begins to inject air into the channels and, in principle, if it is clear that there are significant losses, then the place of the large “hole” is calculated fairly quickly. If it is clear that there are deviations, and there is no way to find a loss point, then instead of air, smoke is started in the system - its leakage will definitely be noticeable. Most often, leak points are poorly connected elements. |

Note! Checking the line for tightness only in words seems simple, simple work. In fact, here, too, requires great experience and technical skills - at a minimum, it is necessary to understand the essence and nuances of actions. Therefore, if this stage must be completed, it is better not to risk it, but to entrust everything to professionals.

These are the rules and tips.

On this, our review came to an end - we got acquainted with the general points and the principle of technology, now we can summarize.

Conclusion

We figured out what it is for and according to which scheme the ventilation is commissioned. We considered a simplified method of testing the system's performance, as well as one where devices are already used.

We hope that the information provided will help you, and if you can not do everything yourself, then at least check how well the hired team is working.

If you want to know even more, we recommend watching the additional thematic video in this article.