About connecting to the water supply system of a submersible

The water supply system in a private house is solved in several ways - it is water intake from a well (well), a tie-in to the general mains, as well as an unauthorized connection to the public water supply, which is highly undesirable because it entails penalties.

So only the first two methods are suitable for us, although in most cases the private sector (especially outside the city) has its own water sources in almost every yard, we will use a submersible pump. This will be discussed below, as well as we will demonstrate the video in this article.

Water in the house

Rules of connection to the centralized water supply

Note. Under the Federal Law of Russia, responsibility for unauthorized unlawful connection to a centralized drinking water supply system is punishable by an administrative fine. So, for individuals it ranges from 1,000 to 1,500 rubles, for officials from 2,000 to 3,000 rubles and for legal entities from 20,000 to 30,000 rubles

- The ability to legally connect to the centralized water supply system is determined solely by the local Vodokanal branch, therefore, first of all, you need to apply there for help.. Performance of work can be carried out both by Vodokanal and third-party organizations, often recommended by the same Vodokanal, except that the price for installation is usually too high. The high cost, as a rule, is motivated by the presence of a license for the production of such works.

- Nevertheless, the instruction allows an independent tie-in, even if you do not have a license for it, but again, the final decision will depend on the organization, in whose department the system is located.. But, in total, this is a question that can be solved, although sometimes it does not do without a certain bribe, so that there is an opportunity to collect a full package of documents.

- But, again, the tie-in process itself will have to be done in the presence of a Vodokanal representative, or they simply do it themselves - all you need to do is pipe liner.. Of course, there is always a certain red tape with documents, but a tie-in to the centralized system will save you from many troubles in the future.

Submersible pump connection

In the case of a well, it is possible to connect the hydrophore to the water supply - as a rule, the distance from the water mirror to the ground level of 7 meters or less is sufficient for this (such pumps are designed to rise up to 9 meters, although there are special depth units operating at 30 meters depth) .

However, now more and more often, submersible pumps are used for wells and boreholes - they are somewhat more expensive, but such instruments are more powerful and have practically no diving limits (they provide water intake even in the deepest wells, more than 50 m).

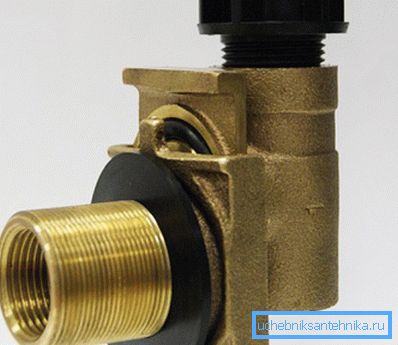

So, we will connect the water supply system from the well or well using a submersible pump and in the well ring, below the freezing point of the soil, you will have to make a hole for the pipe, or rather, there will be a compression corner fitting in the hole connecting the pipe from the pump and the house.

A non-return valve is screwed onto the pump, to which the 32 mm HDPE pipe (low pressure polyethylene) is connected and then it is connected to the corner. In addition, the unit is fixed on the cable, one end of which is displayed outside the well circle outside (the electric cable is run into one hole with the HDPE hose).

To move the HDPE pipe in the borehole, it is much more convenient to install an adapter that will replace the corner compression fitting. This is such an adapter, consisting of two parts, which are fastened to each other with the help of a sliding system such as a sled. Special grease at the junction of the skid holds water.

In the production pipe of the well you will need a diamond crown cutter to make a hole of a suitable diameter with your own hands, but if there is still a casing there, then the hole for access to the production pipe can be cut by a grinder. Now, without connecting the pump.

We start the adapter into the hole to the hole using a rod, which can be made of HDPE with a direct compression fitting at the end (the inside of the adapter has a special place for the threaded connection - in the photo it is black). Fix the adapter nut.

After that, we disconnect the adapter and fasten a pump with a non-return valve and a polyethylene pipe to its removable part - everything here is exactly the same as with well mounting. The assembled unit is lowered into the well, adjusting it with a rod to connect the two parts of the adapter. If the docking does not work out the first time - do not despair - you will surely be able to do this in several attempts.

The pump is fixed with a cable to the wellhead, in addition, there are connecting terminals on the tip to build up the electrical cable, which you will not have enough in any case. You can also connect the cable directly to the trench, only here it is advisable to close the twist with thermal nozzles - first, each twist separately, and then the entire cable, in general.

Note. The bottom of the trench is necessary to fill the sand cushion, approximately 2-3 cm in height - this will evenly distribute the load on the pipe and cable from the pressure of the soil. From above, communication should also be covered with sand so that it covers at least 4-5 cm - this protects the pipe and cable from sharp objects that may be in the ground (stones, glass, wire, etc.). In order not to tamp the sand cushion, it is just poured abundantly with water - shrinkage occurs instantly.

Pumping station

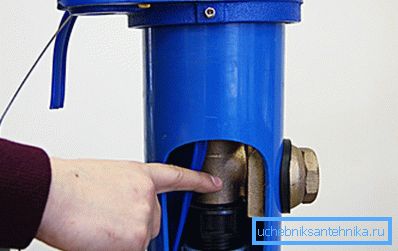

If you use a submersible pump, then you will need to equip a pumping station (usually this is done in a pit that is brickled and concrete), but if you crashed into a centralized water supply, after installing the HDPE, just install one faucet and a coarse filter.

So, let's start from the HDPE wound up in the caisson - if you are afraid of its freezing, then for this purpose install a special tee with a heating cable and a drain valve, and after it set the general shut-off valve.

This is followed by a coarse filter, and then a membrane tank is installed, which provides backup pressure in the system and a unit with a pressure switch and a dry-running sensor. But it is better if these two devices, the relay and the sensor, are installed separately, so in case of failure, you will have to change only one node, and not two at once.

Of course, you can not install the dry-running sensor at all, but then you will not have an emergency shutdown of the engine, if it turns out to be not in water, but in air (when air passes through the device instead of water - it opens the circuit).

Now you just have to install a fine filter (usually it is a flask with a cartridge) or you can even put 2 pieces if the water is dirty and start wiring from this place.

Layout

Note. In the absence of hot water, some people try to use a thermal steam with a connection to the water supply system, but such actions are extremely inefficient and, first of all, because this is a regular kettle, with only constant heating. As economical heaters it is best to use flow-through devices, or a small (10 l) electric boiler.

Currently, hot and cold water cabling is most often performed with polypropylene pipes, but it is marked by its ability to withstand a certain pressure and a constant temperature — these are PN-10, PN-16, PN-20 and PN-25.

The first two types of pipes are used exclusively for distributing cold water, and the second - for hot and heating. But experienced plumbing for plumbing, as a rule, use the PN-20 - it is good, both for cold and for the hot line.

| Diameter in mm | Solder depth in mm | Heating time in seconds. | Cooling time in min. |

| 20 | 14–17 | 6 | 2 |

| 25 | 15–19 | 7 | 2 |

| 32 | 16–22 | eight | four |

| 40 | 18-24 | 12 | four |

| 50 | 20–27 | 18 | four |

| 63 | 24–30 | 24 | 6 |

| 75 | 26–32 | thirty | 6 |

| 90 | 29–35 | 40 | eight |

Table of welding parameters of SPR pipes

Pay attention to the table - you will see there the time of soldering and also the optimal immersion of the pipe in the fitting. Compliance with these parameters will allow you to maintain the permeability of the pipes as much as possible and the pressure in your taps will always be good.

Conclusion

In conclusion, I would like to say a few words about the bathrooms, for example, make sure you connect the toilet bowl to the water supply, faucet on the bathroom, sink or electric boiler through the taps. This will allow the prevention, repair and replacement of a node, without disconnecting the entire plumbing in the house.