Adjusting the water pressure switch for the pump

The pressure switch is a key element in the automation of the pump or pumping station, it gives a signal to turn on and off the pump. Depending on the manufacturer and model, the factory settings may differ, but, as a rule, the lower threshold for switching on the pump is set at a pressure of 1.4–1.8 bar, and the threshold for switching off is 2.5–3 bar. But sometimes these settings threshold of operation is not sufficient for the normal operation of plumbing devices, so it is necessary to adjust the water pressure switch for the pump, to choose individual parameters for its on and off.

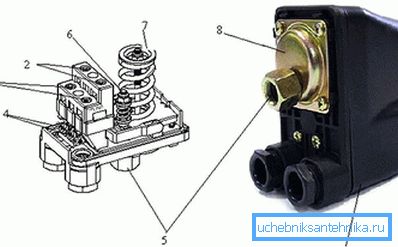

Design and principle of operation

Before you start setting up the relay, you need to understand the design and principle of its work. The design of the relay is quite simple and consists of contacts, spring-loaded plate, which is affected by water pressure.

- Housing

- Contact group for pump connection.

- Terminals for mains connection.

- Grounding terminals.

- Nut for connecting the relay to the water supply.

- Spring differential pressure adjustment.

- Spring adjustment minimum pressure.

- The node where the piston and membrane.

On a metal base is fixed at one end of a metal platform, which can rise and fall under the action of the piston. The piston is driven by water pressure. The platform has two springs (6,7), a large spring (7) counteracts the force of the piston (water), thereby balancing it. The small spring (7) does not take effect immediately, but after the platform rises to a certain height, and as soon as the platform touches the smaller spring, the piston is countered by the forces of both springs and the resistance of the piston force increases, from that moment the platform needs to rise quite a bit. the contacts open and the pump is turned off. For opening and closing the contacts meets a small hinge with a spring. As soon as the platform rises above this hinge, the contacts bounce down and the electrical circuit opens, as soon as the action of the piston (water) force weakens, the platform goes down and the contacts close.

A large spring is responsible for turning on the pump, that is, for the lower limit of pressure, and with the help of a small spring, the moment the pump is turned off is controlled, or rather, the difference between switching on and off is set.

Customization

Based on the principle of the relay, its setting is to change the stiffness between the platform, which is affected by water pressure and contacts. Adjustment is carried out by changing the stiffness of the spring, which is either compressed or weakened, by adjusting nuts. Before starting the adjustment, it is necessary to fix the indicators of the pressure gauge during switching on and off of the pump. Next, disconnect the relay from the network, and remove the housing cover. Using a wrench, unscrewing or twisting the nuts, adjust the necessary parameters:

- if it is only necessary to change the lower switching threshold (increase or decrease), then it is necessary to press or release the nut on the spring (7);

- to increase or decrease the upper limit of the pump shutdown, it is necessary to fasten or unscrew the nut on the spring (6), when tightening - we raise the cut-off limit of the pump, and when unscrewing, on the contrary, lower it, increasing the difference between on and off;

- if you need to change two parameters at once, then the lower limit is first adjusted using a spring (7), and then we set the difference using a spring (6);

All changes need to be monitored with a pressure gauge. It is worth considering that by changing the pressure difference, we reduce or increase the duration of the pump, and this will appear on the change in pressure in the water supply network. If the pressure difference is small, the pressure in the network will be “smooth” without visible drops, but the number of pump starts will increase, which may affect its service life.

Features of adjustment

When adjusting, you need to remember that the upper pressure should not be higher than the maximum pressure that a pump can create (you can see it in the pump’s rating data). The upper pressure must not exceed 80% of the maximum allowable pressure for a specific model, and these parameters are indicated in the instructions for the relay. Also before setting you need to check the air pressure in the pear of the hydraulic tank - it must be less than 0.2 bar lower threshold of the pump. Another requirement for adjustment is the difference between the on and off pressure, it should be within 1–1.5 bar. Changing the parameters, you can not tighten the nuts until it stops, this can lead to the fact that the relay stops altogether.

Video

This video shows how to adjust the pressure switch for a pump: